Piezoelectric electroacoustic transducer

An electro-acoustic transducer and piezoelectric technology, applied in piezoelectric/electrostrictive transducers, piezoelectric/electrostrictive/magnetostrictive devices, sound-emitting devices, etc., can solve the problem of low production efficiency, vibrating sheet Changes in characteristics, low sound conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

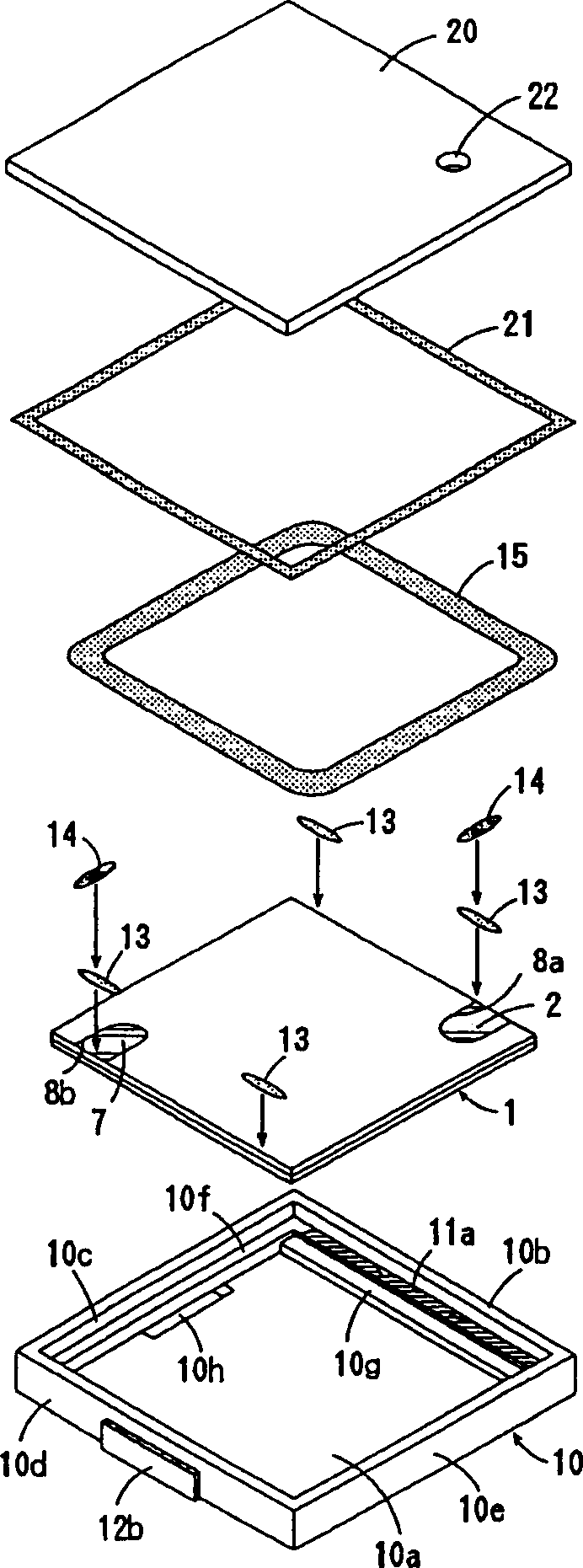

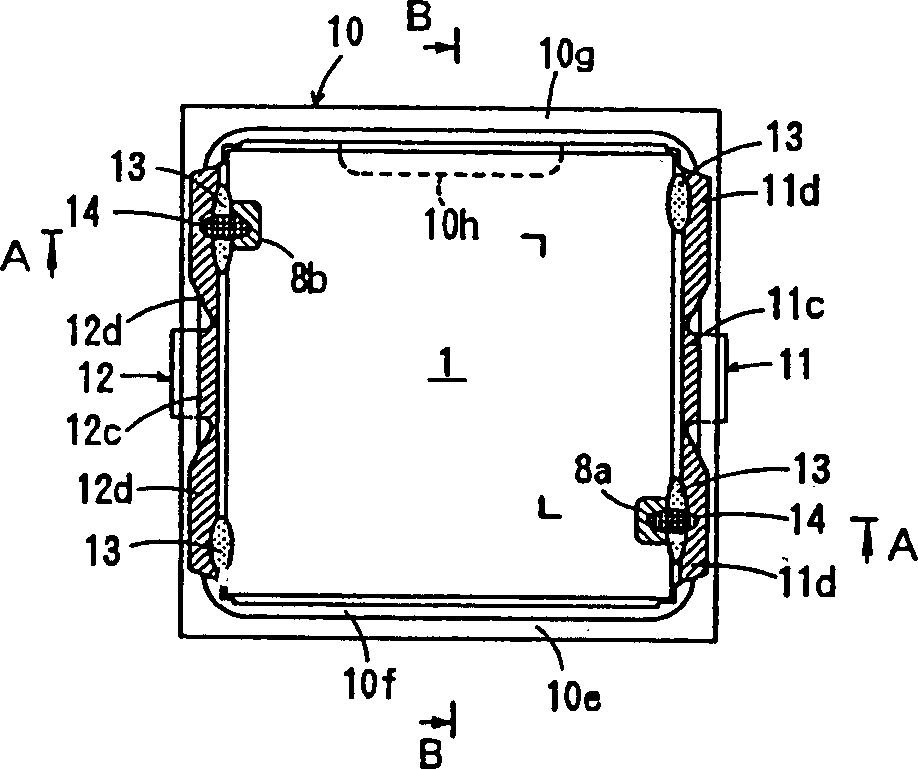

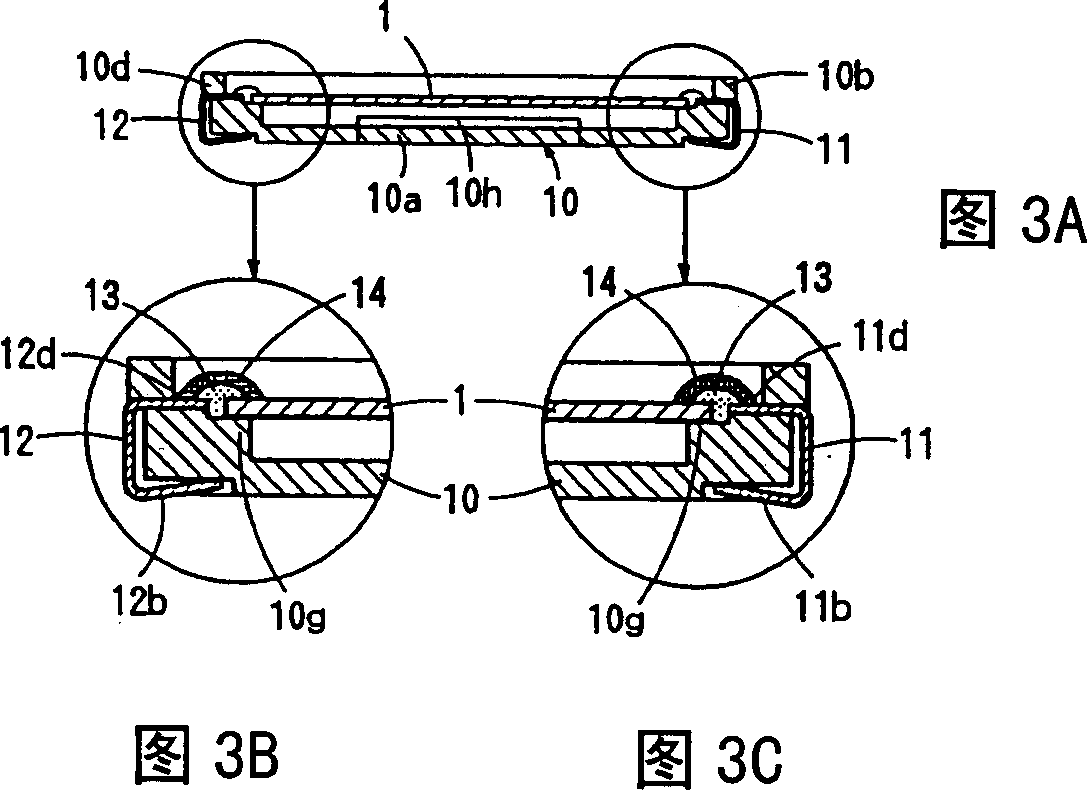

[0025] figure 1 - 4B represents the surface-mountable piezoelectric electroacoustic transducer according to the first preferred embodiment of the present invention.

[0026] The electroacoustic transducer of the first preferred embodiment is suitable for devices used in a wide frequency range, such as a piezoelectric receiver, and includes a piezoelectric vibrating piece 1, a container 10, and a cover plate 20 having a laminated structure. The combination of the container 10 and the cover plate 20 gives the housing of the piezoelectric electroacoustic transducer.

[0027] Such as Figure 5 and 6 As shown, the vibrating plate 1 is preferably formed by laminating two piezoelectric ceramic layers 1a and 1b. At the top and bottom surfaces of the vibrating piece 1, two main surface electrodes 2 and 3 are provided on the main surface thereof, and an internal electrode 4 is also provided between the ceramic layers 1a and 1b. Such as Figure 5 and 6 As indicated by the thick arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com