Fiber cutting machine used for producing staple fibers

A technology of fiber cutting machine and artificial filament, which is applied in fiber cutting, fiber processing, textile and paper making, etc. It can solve the problems of blade wear, low hardness, and inability to cut neatly, and achieve the effect of reducing bending load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

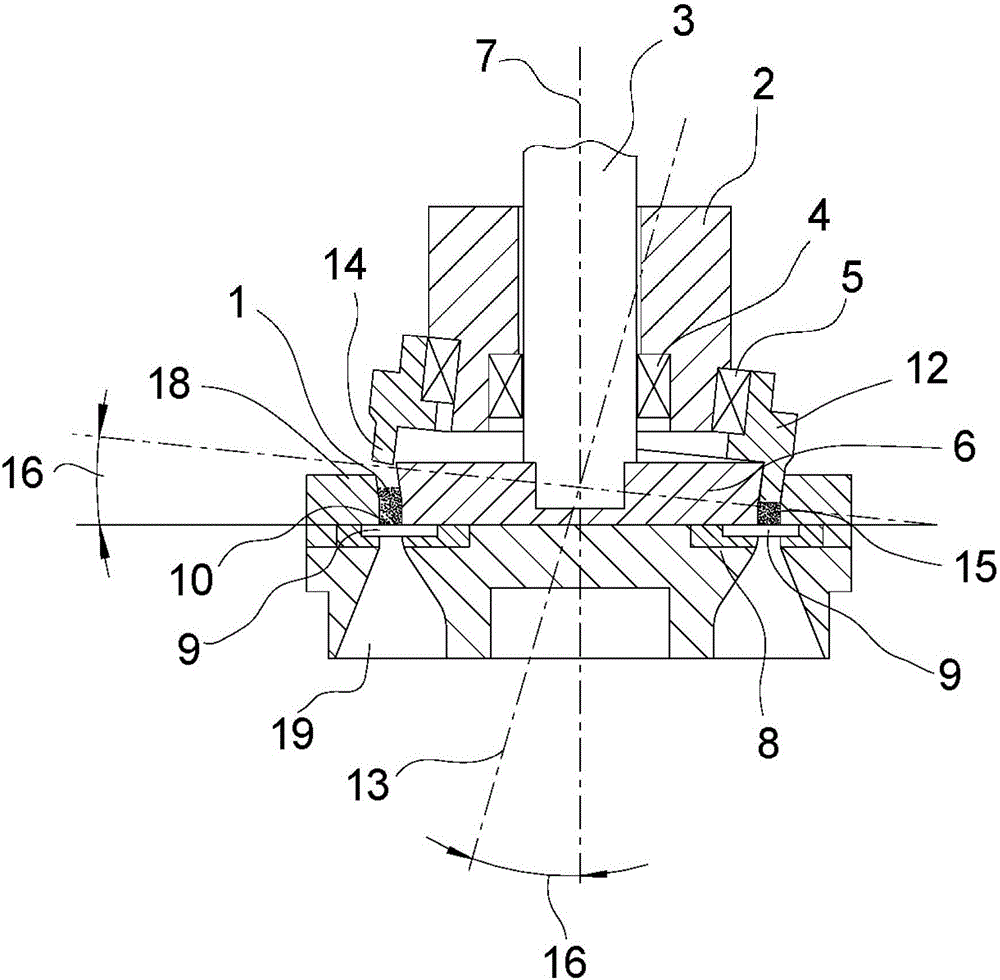

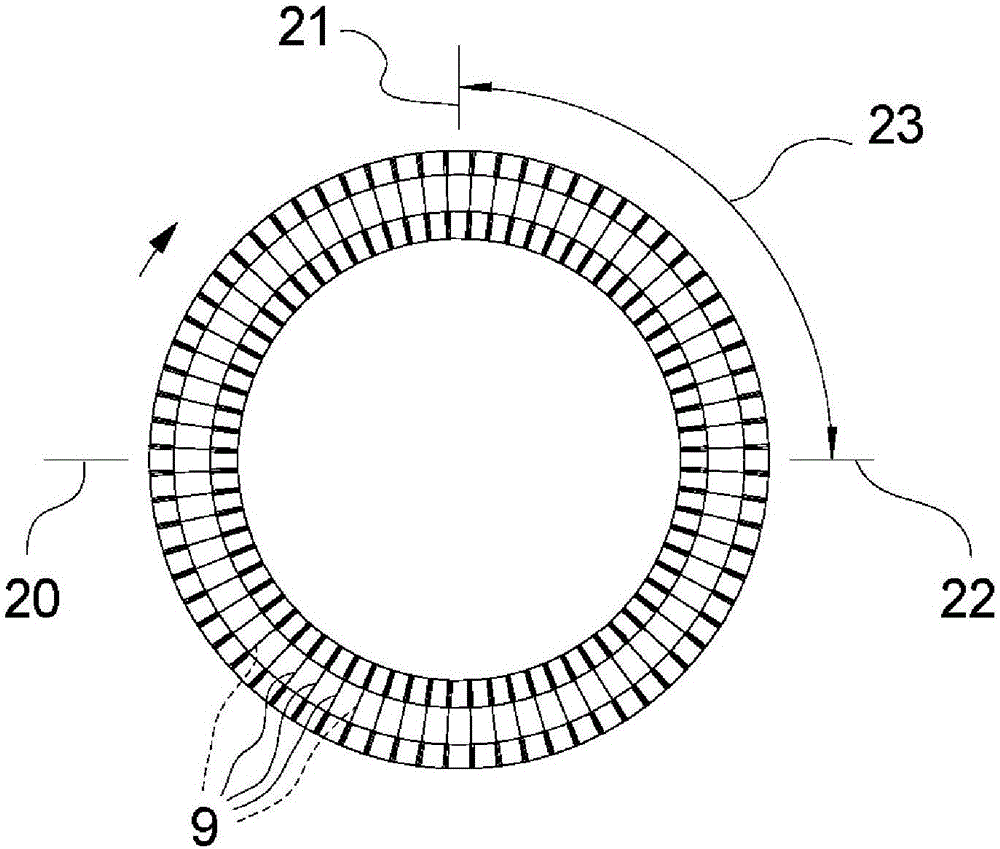

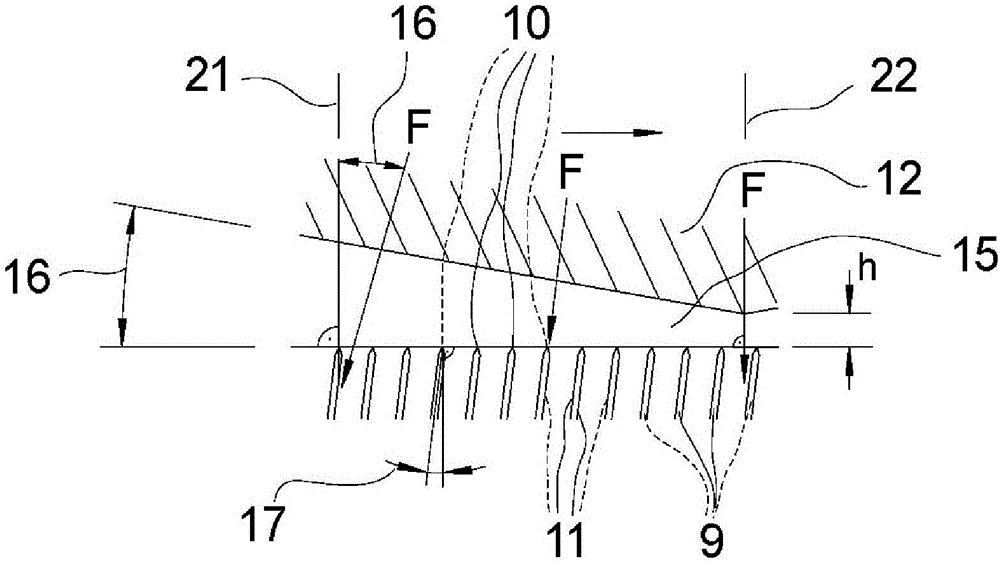

[0020] All three figures have the same reference numerals. exist figure 1 A cross-sectional view of an embodiment of a fiber cutter according to the present invention is schematically shown in . A plurality of tools 9 are arranged in a ring and are held horizontally in the associated tool receptacle 8 . A tool receptacle 8 is arranged in the tool holder 6 . The tool holder 6 is rotatable via the drive shaft 3 . The axis of rotation is formed by the tool carrier axis 7 , which runs centrally through the tool carrier 6 and the drive shaft 3 . The drive shaft 3 is held in a stationary bearing housing 2 by means of bearings 4 . Furthermore, the bearing housing 2 accommodates on its outer circumference a pressure ring bearing 5 , by means of which a pressure ring 12 is held rotatably on the bearing housing 2 . The pressure ring 12 and the associated pressure ring carrier 5 are arranged such that an opening angle 16 is formed between the pressure ring axis 13 , about which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com