Semiconductor device

A semiconductor and thin film transistor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problem of uneven crystal grain size, and achieve the effects of excellent characteristics, reduced characteristic variation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

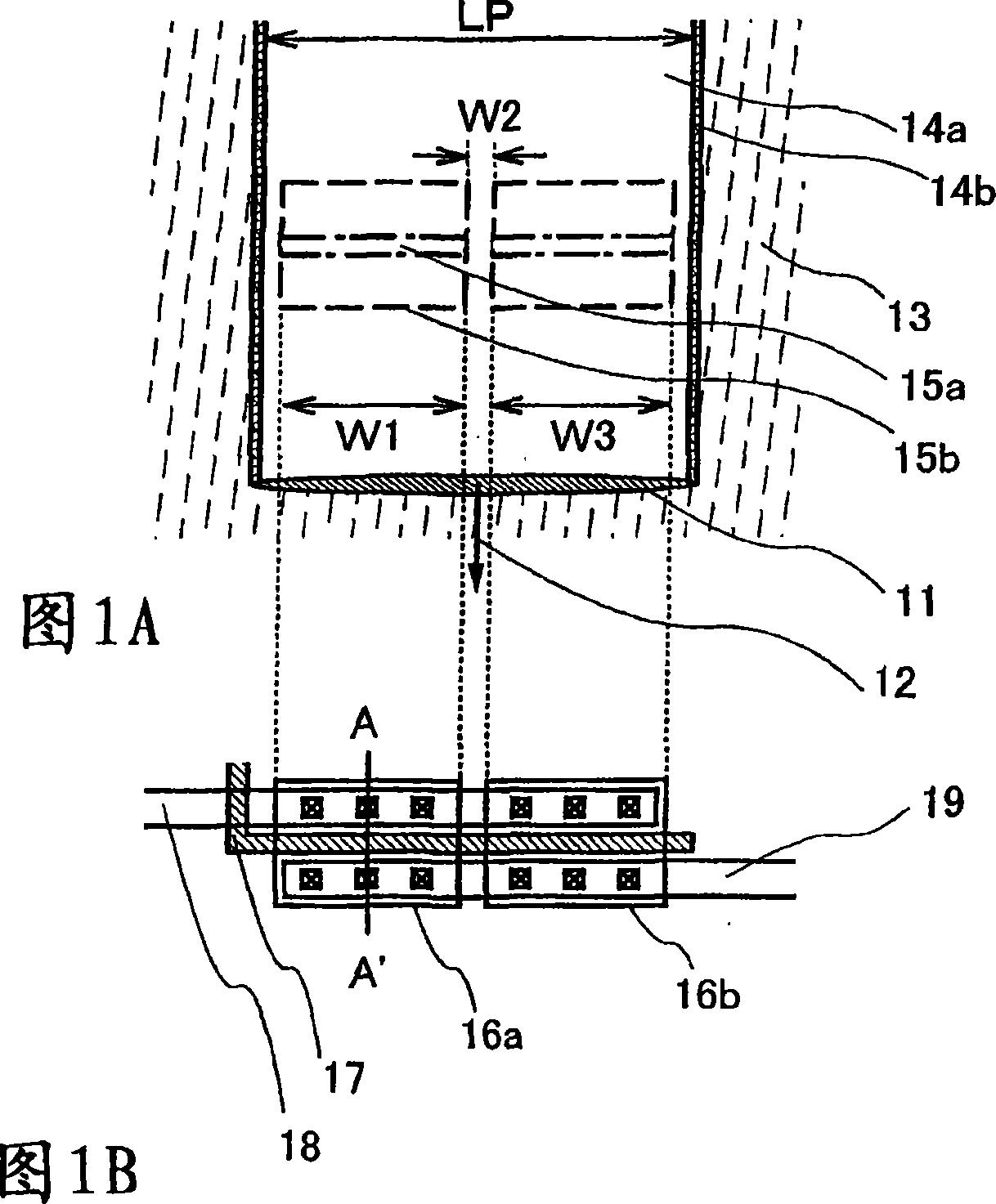

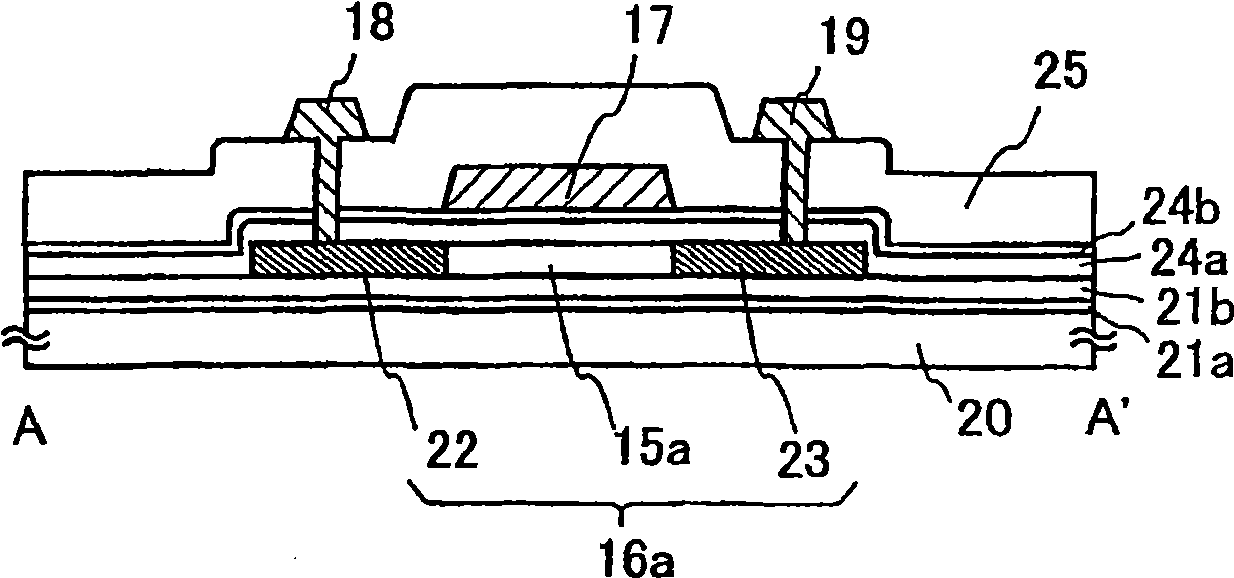

[0042] A state in which a CW laser beam is scanned on the surface of a semiconductor film formed on a substrate and a manufactured TFT will be described with reference to FIGS. 1A to 1C.

[0043] FIG. 1A is a plan view showing a scanning state of a laser beam 11 on the surface of an amorphous semiconductor film. A laser beam 11 has an elongated elliptical beam spot and is scanned in a scanning direction 12 indicated by an arrow in the figure to partially form a crystal region.

[0044] Although not shown in FIG. 1A, since the figure shows an example of forming a top gate type TFT, a base insulating film is formed over a substrate having an insulating surface and an amorphous semiconductor film is formed thereon.

[0045] In the crystallization process of an amorphous semiconductor film, a continuous wave solid-state laser is used in this embodiment mode and a laser beam having the second, third, or fourth harmonic of the fundamental wave is emitted onto the semiconductor film ...

Embodiment approach 2

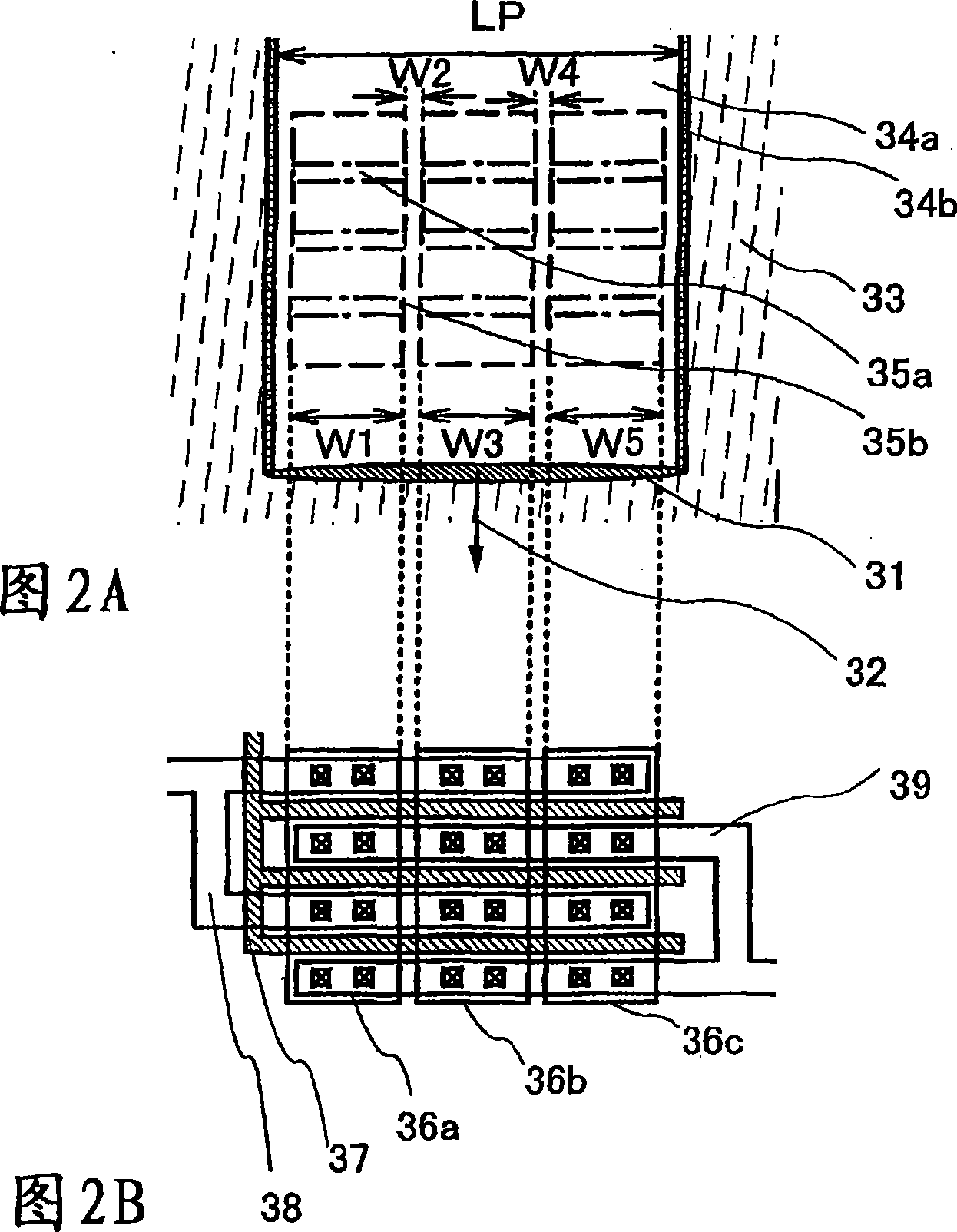

[0068] A state in which a quasi-CW laser beam is scanned on the surface of a semiconductor film formed over a substrate and a manufactured TFT are described with reference to FIGS. 2A and 2B.

[0069] FIG. 2A is a plan view showing a scanning state of a laser beam 31 on the surface of an amorphous semiconductor film. A laser beam 31 has an elongated elliptical beam spot and is scanned in a scanning direction 32 indicated by an arrow in the figure to partially form a crystal region.

[0070] Although not shown in FIG. 2A, since the figure shows an example of forming a top gate type TFT, a base insulating film is formed on a substrate having an insulating surface and an amorphous semiconductor film is formed thereon.

[0071] In the process of crystallizing the amorphous semiconductor film, YVO with an output of 1.8W was used 4 laser with a repetition rate of 80 MHz and a pulse width of approximately 12 ps. The pulse repetition rate is not limited to 80 MHz in the present inve...

Embodiment 1

[0088] In Embodiment 1, refer to image 3 The structure of the laser irradiation equipment will be described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com