Bearing device for wheel

A bearing device and wheel technology, applied in the directions of bearings, axles, wheels, etc., can solve the problems such as the deterioration of the vibration accuracy of the side of the wheel mounting flange 581, and achieve the effect of reducing the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

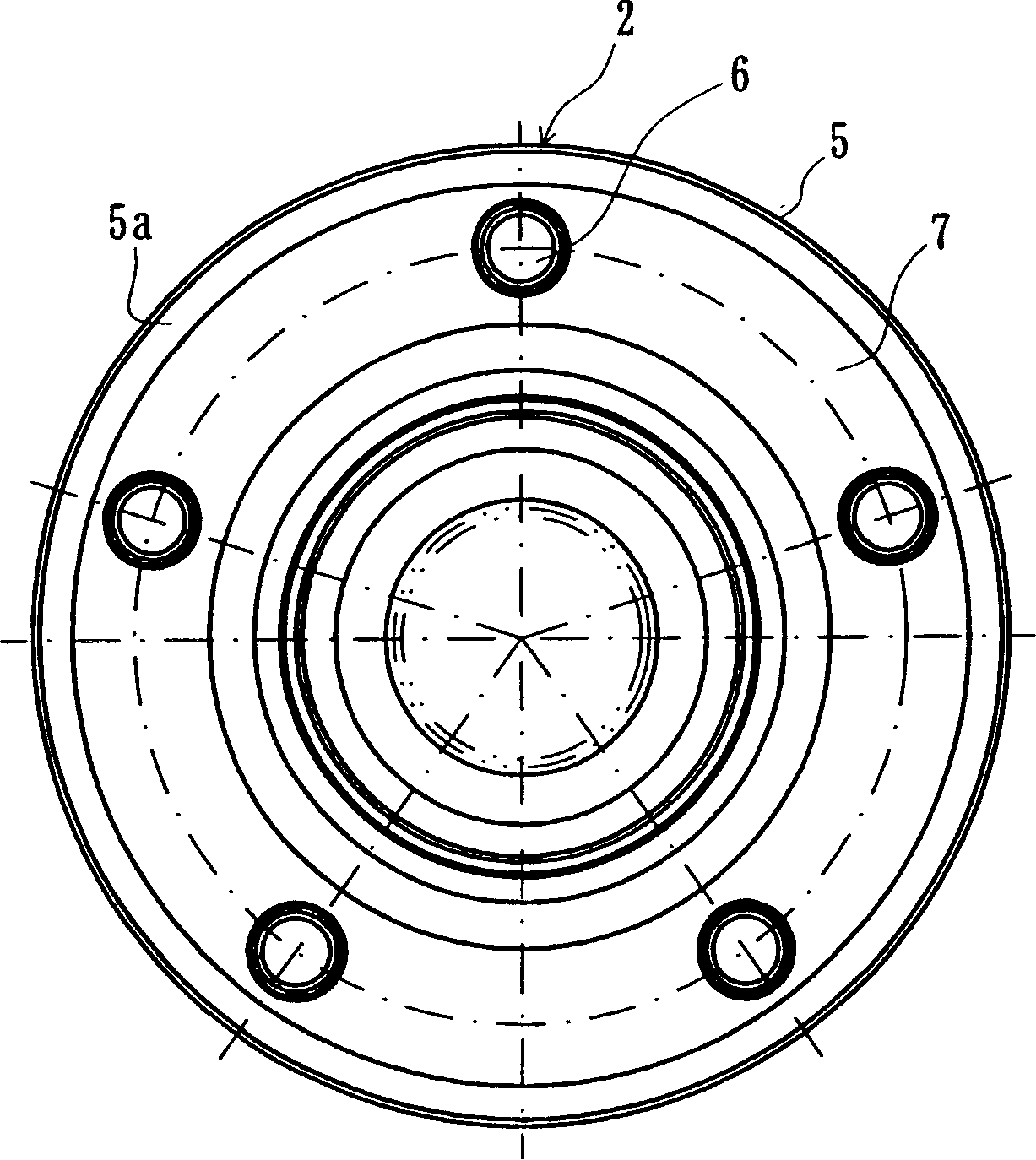

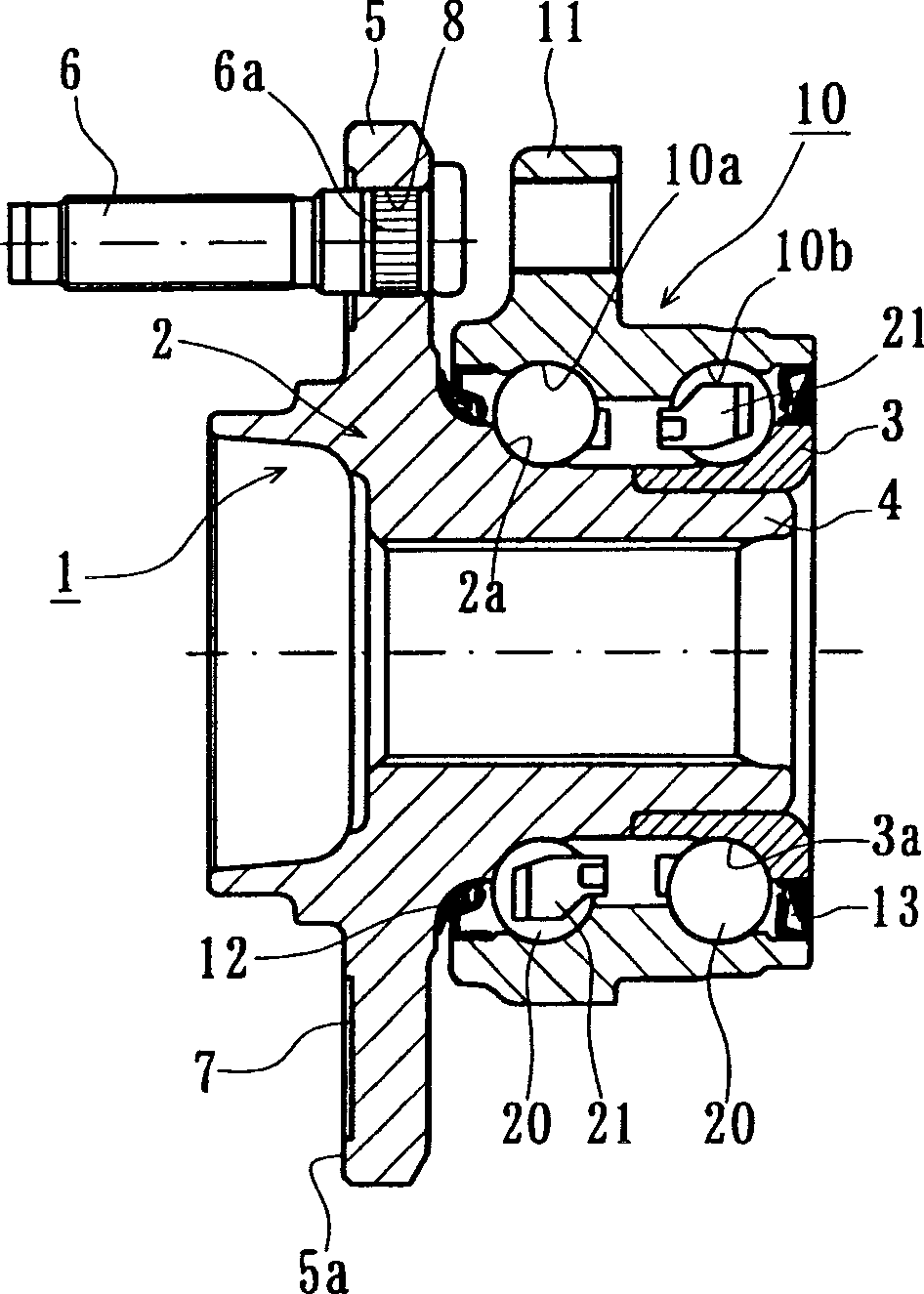

[0074] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Fig. 1 shows a first embodiment of a bearing device for a wheel according to the present invention, (b) is a longitudinal sectional view, and (a) is a side view thereof.

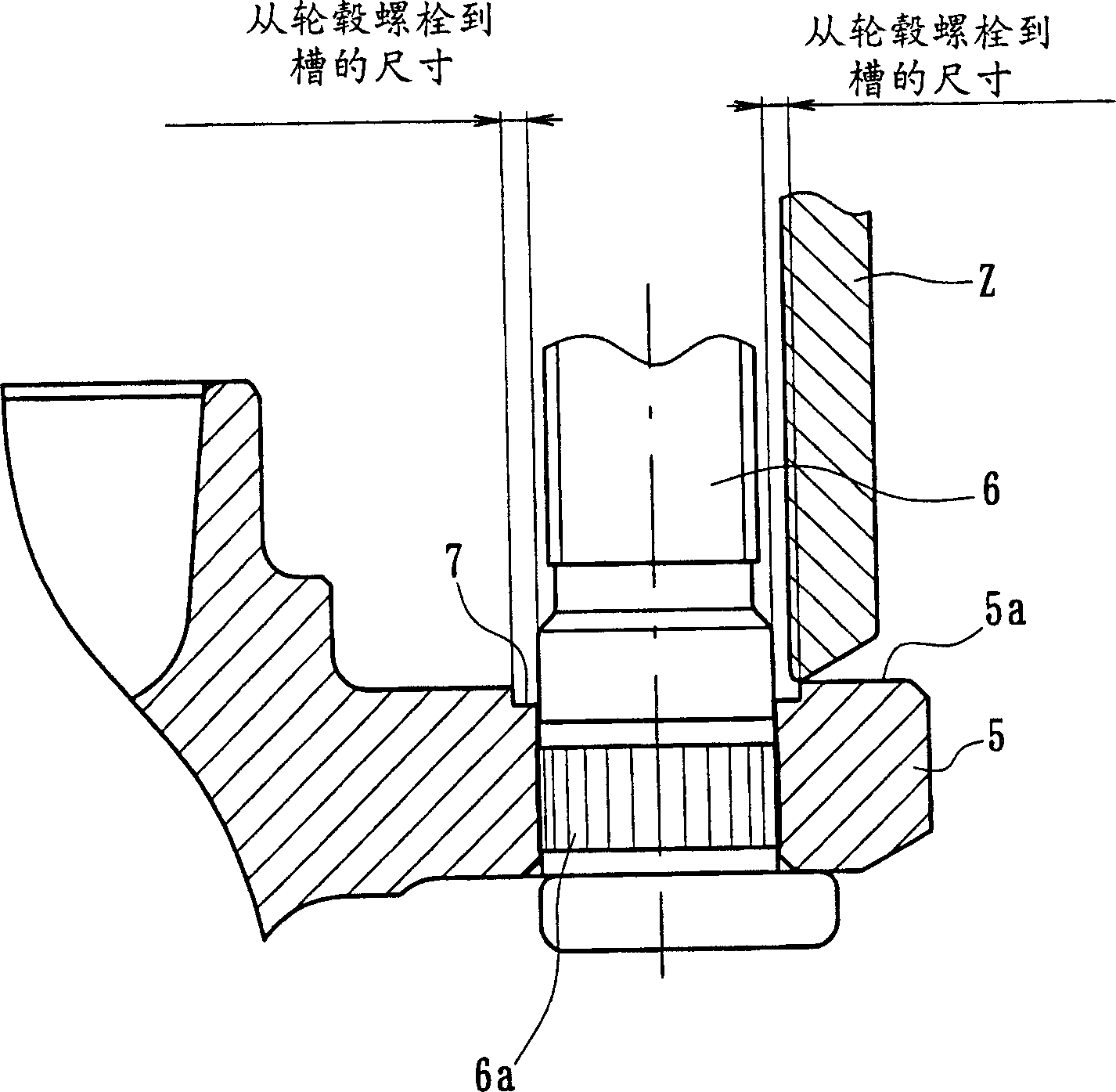

[0075] This bearing device for a wheel has an inner member 1 , an outer member 10 and a plurality of rows of rolling bodies 20 , 20 . The inner part 1 is composed of a hub 2 and an inner wheel 3 . The inner ring 3 is press-fitted into a small-diameter stepped portion 4 formed at the inner end portion of the hub 2 . In addition, an inner inner rotational surface 3 a is formed on an inner inner rotational surface 2 a inside the outer circumference of the hub 2 and an inner inner rotational surface 3 a on the outer circumference of the inner ring 3 . In addition, a wheel mounting flange 5 for mounting a wheel (omitted in the figure) is integrally formed on the outer end of the hub 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com