Solid state surface catalysis reactor

A solid-state surface and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

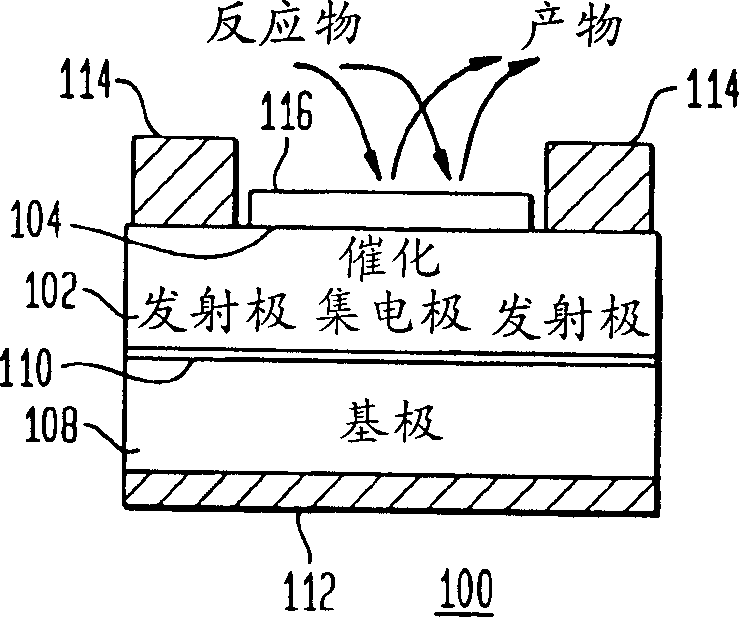

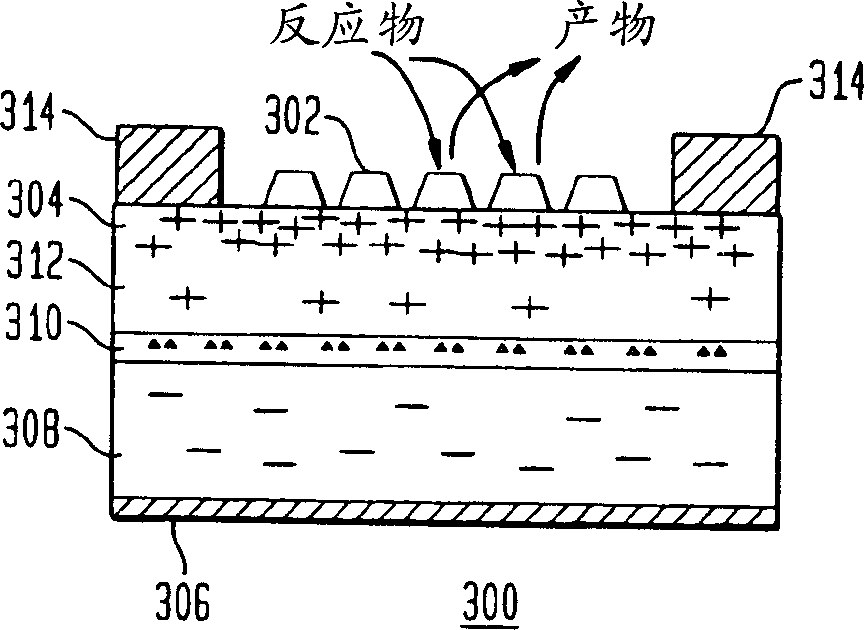

[0038] An exemplary embodiment of the present invention uses electrons as hot carriers and a p-n junction diode as a semiconductor diode. The base is an n-type semiconductor and the emitter is a p-type semiconductor. The forward bias of the p-n junction diode injects minority carrier electrons into the conduction band of the p-type emitter where they become minority carriers. The minority carriers diffuse and migrate into the catalytic collector, and may also resonantly couple into the excited structure of the adsorbate-catalyst system, provided that the distance between the junction (junction) and the catalytic collector is low It may be several times longer than the diffusion length of the minority carriers in the p-type semiconductor. For example, when InSb, InAs or some InGaAsSb alloys are the semiconductor, the diffusion length can vary from about 100 nanometers to several micrometers.

[0039] According to the invention, said minority carrier electrons are injected or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com