Gas phase rust-proofing plastic sealing bag

A technology of plastic sealing and gas phase rust prevention, applied in the direction of bags, sacks, flexible coverings, etc., can solve the problems such as the lack of rust prevention and preservation of metal objects, the ideal method, etc., to achieve good rust prevention effect and enhanced vaginal barrier performance. , The effect of low oxygen and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The following components by weight are mixed and granulated,

[0024] Cyclohexylamine Benzoate 0.5%

[0025] Ammonium Benzoate 2%

[0026] Benzotriazole 1%

[0027] Polyethylene balance.

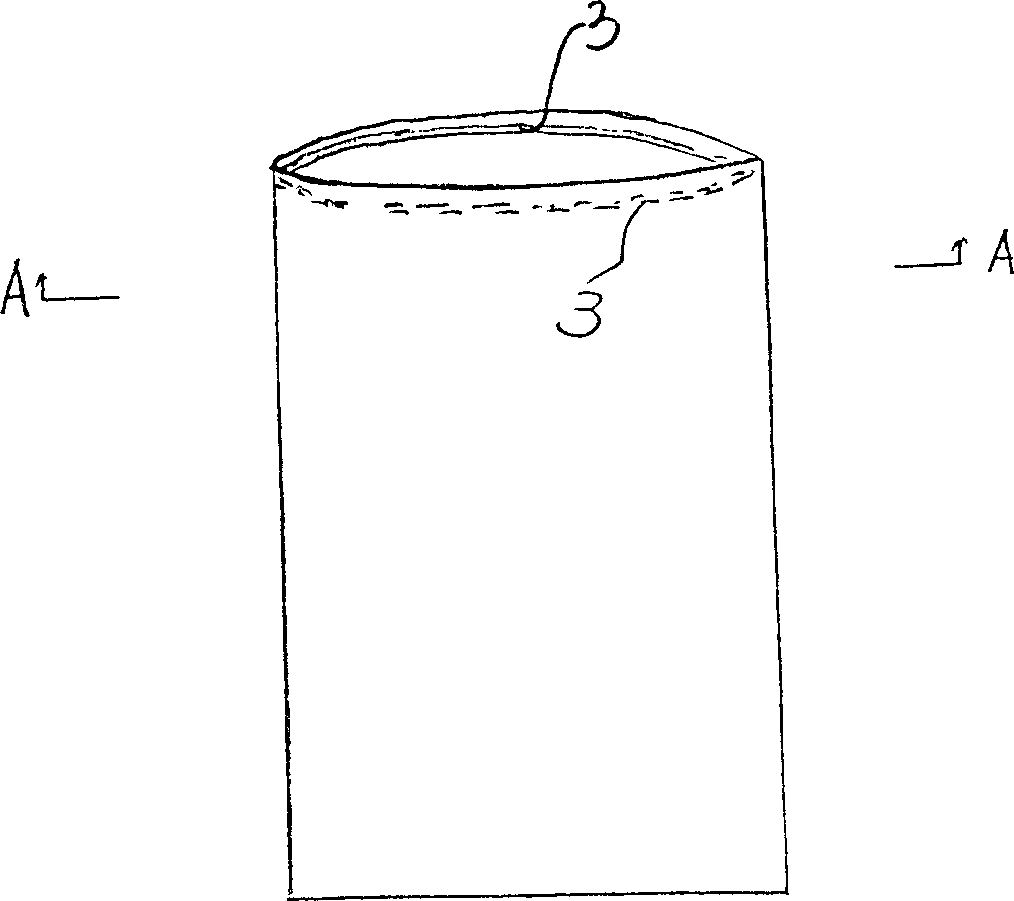

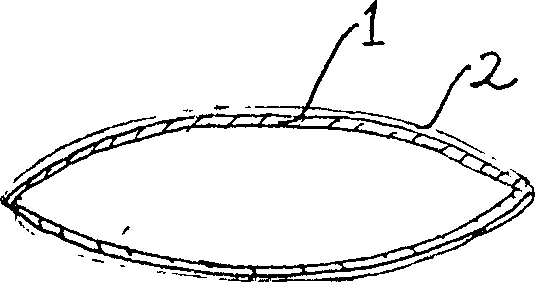

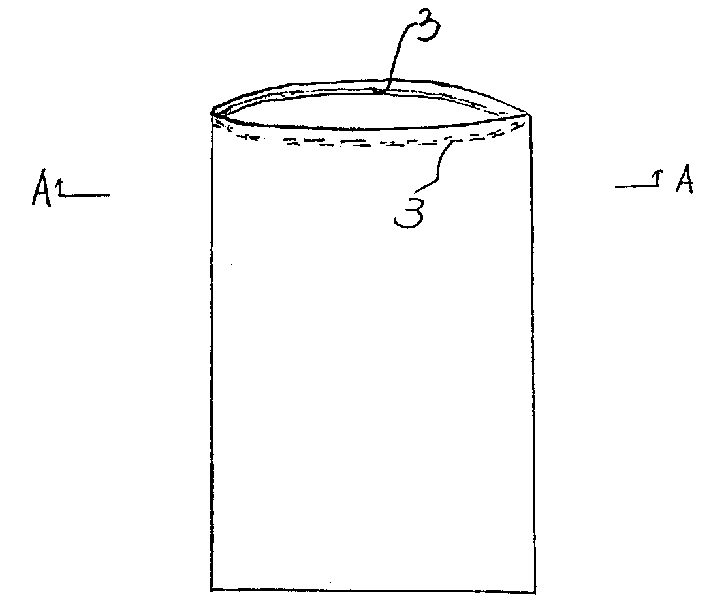

[0028] Then, it is blown into a vapor phase antirust film 1 with a thickness of 6-12 wires (6, 8, 10, 12 wires) by conventional blow molding technology. A layer of nylon film 2 with high barrier performance with a thickness of 1 to 2 wires (example 1, 1.5, 2 wires) is compounded on this film, and then made into a bag, and a commercially available toothless zipper type sealing strip is installed at the mouth of the bag 3. The product is obtained, and the anti-rust film inner layer 1 of the product is composed of the following components by weight:

[0029] Cyclohexylamine Benzoate 0.5%

[0030] Ammonium Benzoate 2%

[0031] Benzotriazole 1%

[0032] Polyethylene balance.

Embodiment 2

[0034] The inner layer of anti-rust film is made of the following components by weight:

[0035] Cyclohexylamine Benzoate 1.5%

[0036] Ammonium Benzoate 1.5%

[0037] Benzotriazole 0.5%

[0038] Polyethylene balance.

[0039] All the other are with embodiment 1.

Embodiment 3

[0041] The inner layer of anti-rust film is made of the following components by weight:

[0042] Cyclohexylamine Benzoate 2.5%

[0043] Ammonium Benzoate 0.5%

[0044] Benzotriazole 2%

[0045] Polyethylene balance.

[0046] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com