Heat sensitive overheat protective device

An overheat protection and thermal technology, applied in thermal switch parts, heating/cooling contact switches, etc., can solve problems such as failure to achieve power failure, failure to achieve power failure, and reduced life of bimetallic actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

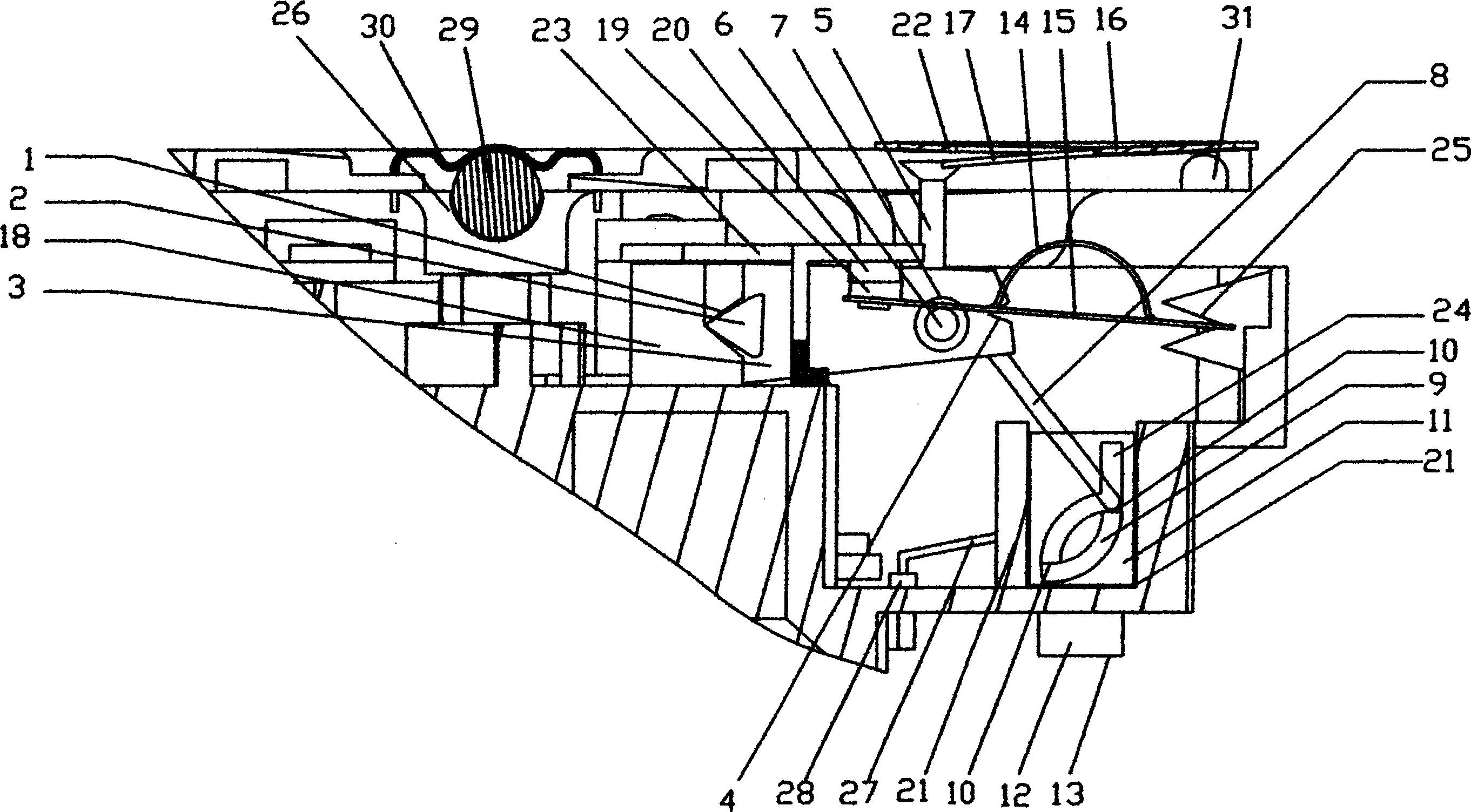

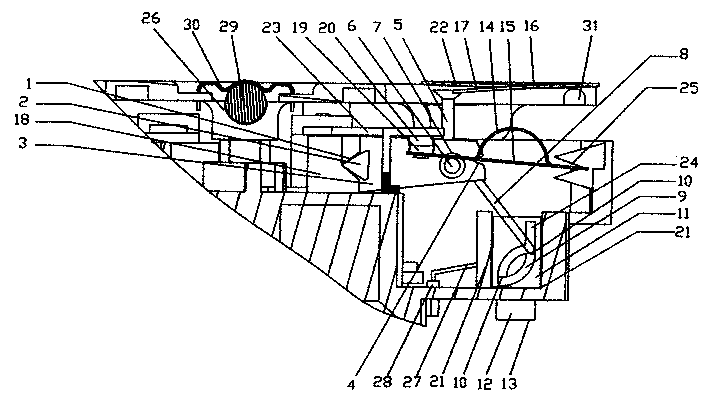

[0036] The present invention comprises molded body 18, action arm 3, passive spring 8, U-shaped spring sheet 14, bimetallic actuator 16, sliding push rod 5, movable block 11, pressure spring 27 and fixed pressure spring on the molded body The pressure spring seat 28, the chute 9, the chute limit step 10.

[0037] The molded V-shaped edge 1 on the molded body 18 is matched with the V-shaped fulcrum 2 on the action arm, and the V-shaped edge 125 on the molded body is matched with the current-carrying member 15 on the U-shaped spring sheet , the action arm cutting edge 4 matches and interacts with the U-shaped spring piece 14, so that the action arm 3 and the U-shaped spring piece 14 are hit, and the two contacts 19, 20 on the current-carrying part 15 on the U-shaped spring piece are also in contact with the insurance The two corresponding contacts of the connection terminal 23 are engaged (only one set is drawn for ease of understanding), and the two sets of contacts are in a ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com