Micromechanism and its manufacture

A technology of micro-mechanics and micro-mechanical components, applied in the field of multi-layer micro-mechanical devices, can solve problems such as difficulty in obtaining a high quality factor, process quality degradation, etc., achieve high accuracy, reduce process loss, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

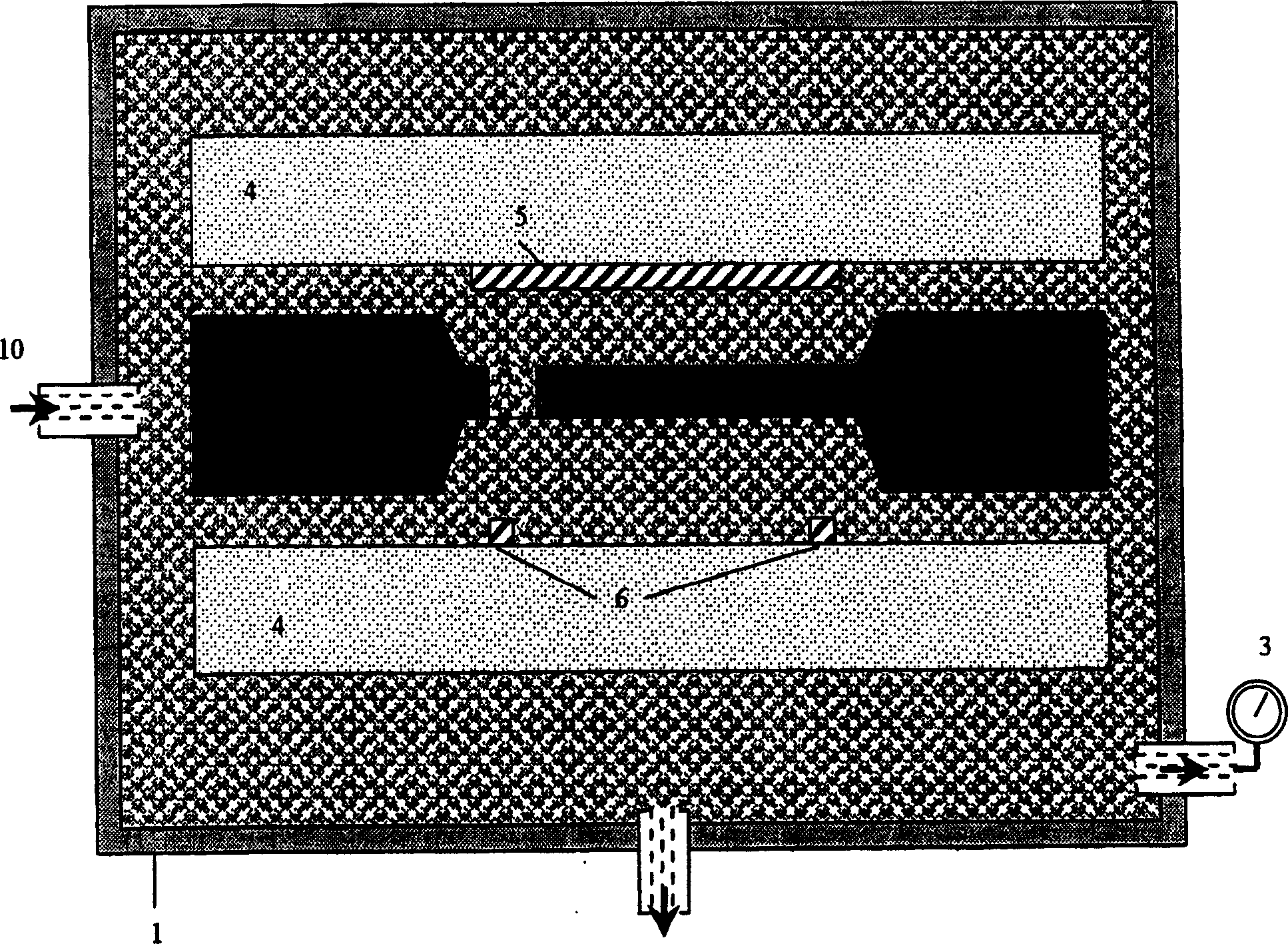

[0022] refer to figure 1 , the connecting chamber 1 in which the method of the invention is carried out is maintained at a controlled low pressure or vacuum by means of a pump (not shown) connected to the outlet 2 and the pressure gauge 3 . The components of the device to be produced are arranged in this chamber 1 . In this embodiment, the device is a resonant accelerometer or gyroscope.

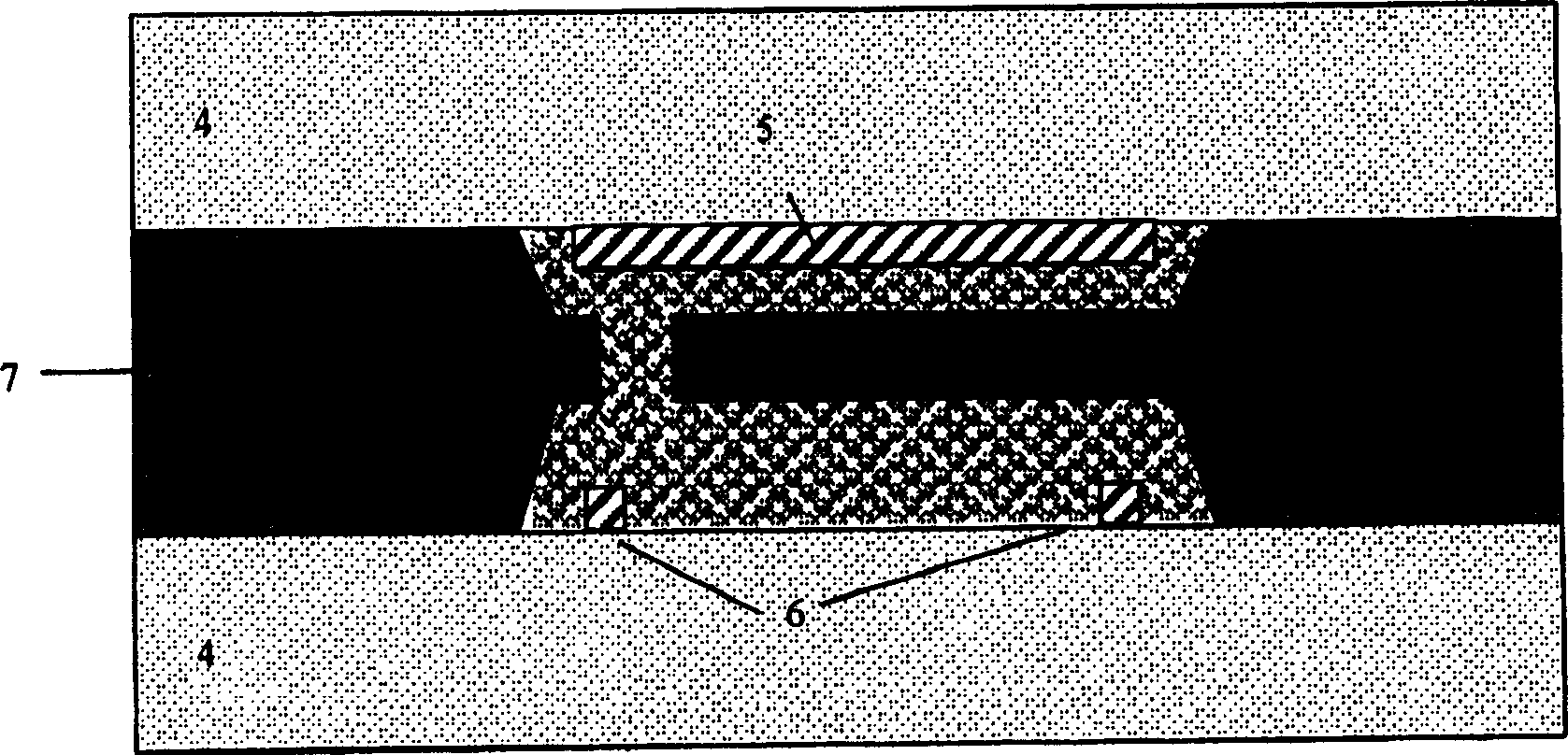

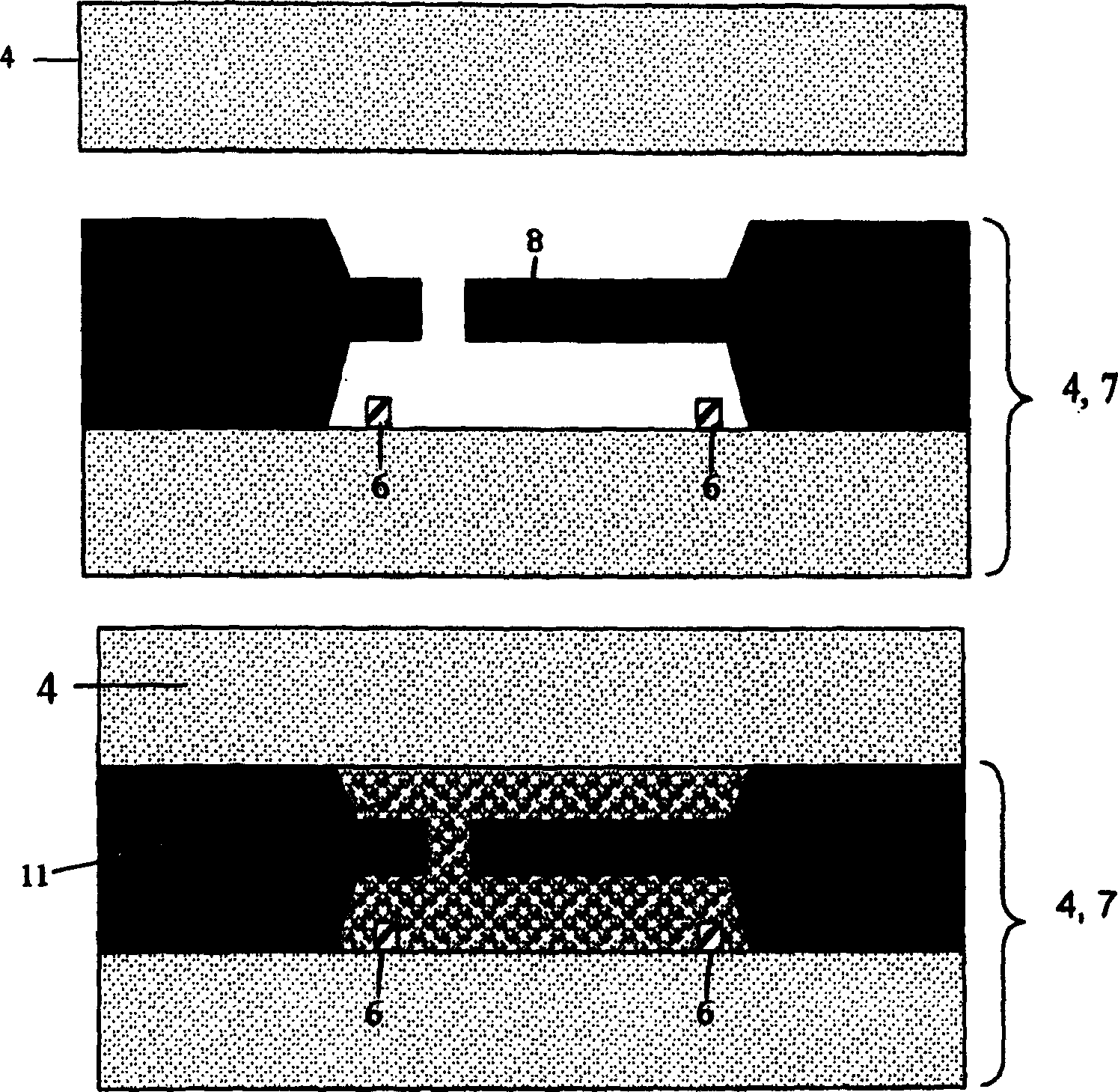

[0023] The components in the connection chamber 1 include a first and a second encapsulation layer 4 . These layers are formed from glass, silicon or silicon sputtered from glass. Formed on the surface of one of the encapsulation layers 4 is a metal layer 5 which provides a detection circuit for the end product of the process. Formed on the other encapsulation layer 4 are one or more getter components fabricated from titanium or other suitable getter material. Located between the two encapsulation layers 4 is a silicon layer 7 which is processed to form device components 8 thereon.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com