Streamlined automatic open-close water gate

An automatic opening and streamlined technology, applied in water conservancy projects, coastline protection, marine engineering and other directions, can solve the problems of increasing the dead weight of the sluice gate and increasing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the accompanying drawings. The same reference numerals are used to designate the same parts throughout the figures.

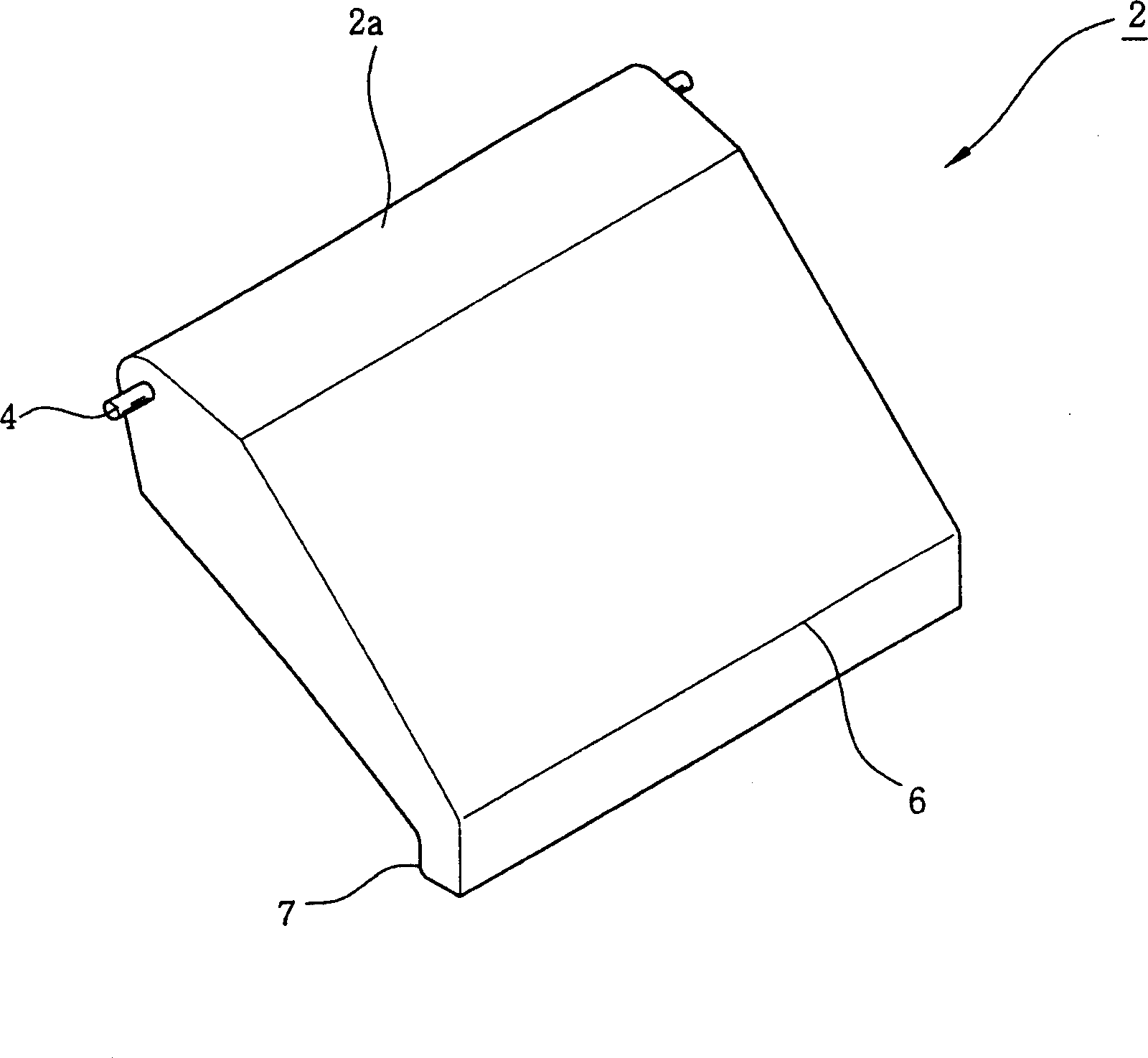

[0043] figure 1 The streamlined automatic opening / closing water gate 2 of the present invention is shown. A pair of pivot shafts 4 are formed on both sides of the upper part of the water gate 2, so that the water gate can be pivotally opened.

[0044] The upper portion of the water gate 2 has a streamlined portion 2a, thereby reducing resistance to water. The bottom of the sluice 2 has a curved portion 6, which can be in close contact with the bottom of the waterway to prevent water leakage and can withstand the pressure of the water.

[0045] There is a slightly arc-shaped portion 7 at the bottom of the curved portion 6, thereby reducing the water pressure and facilitating the lifting of the water gate.

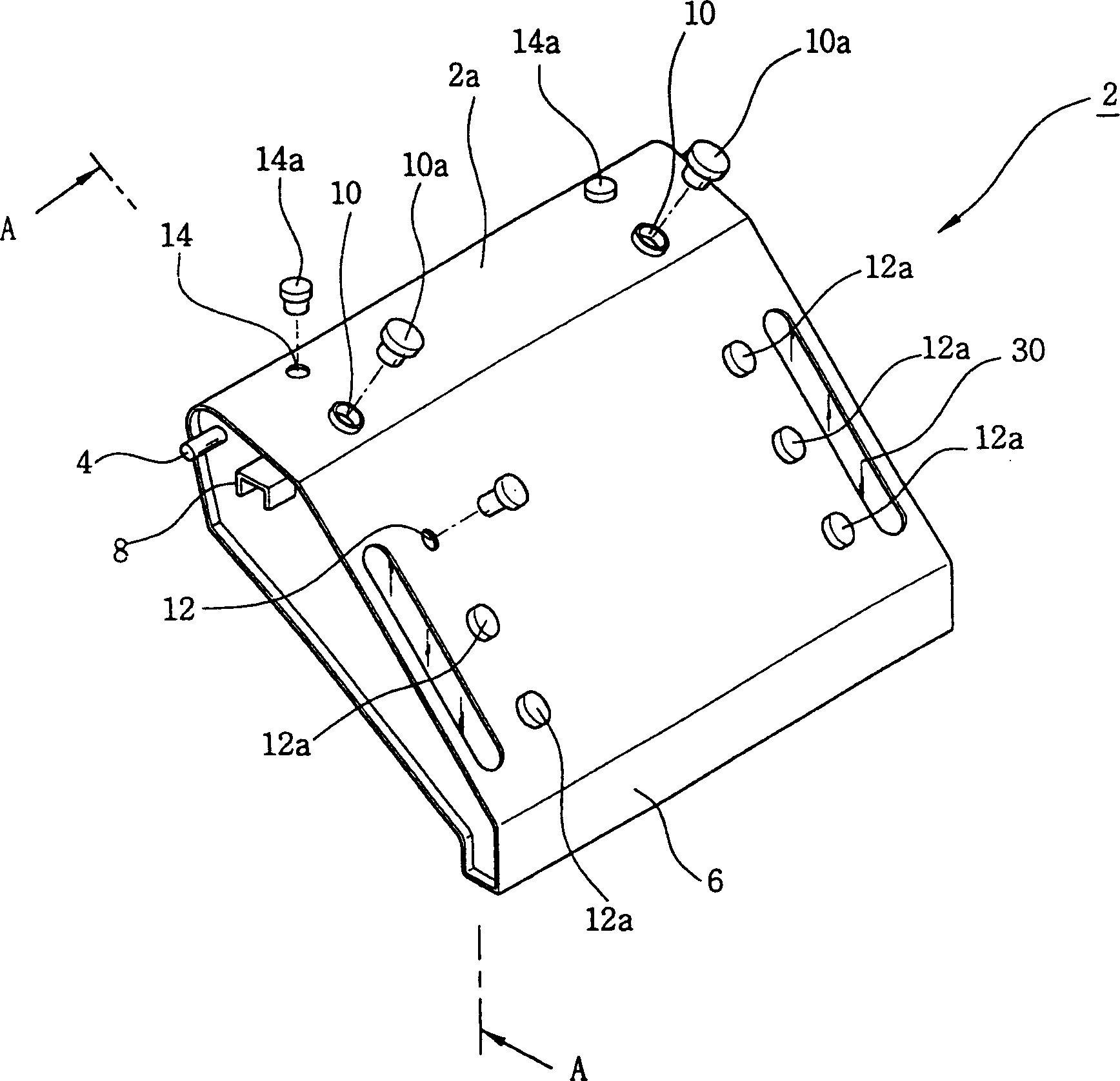

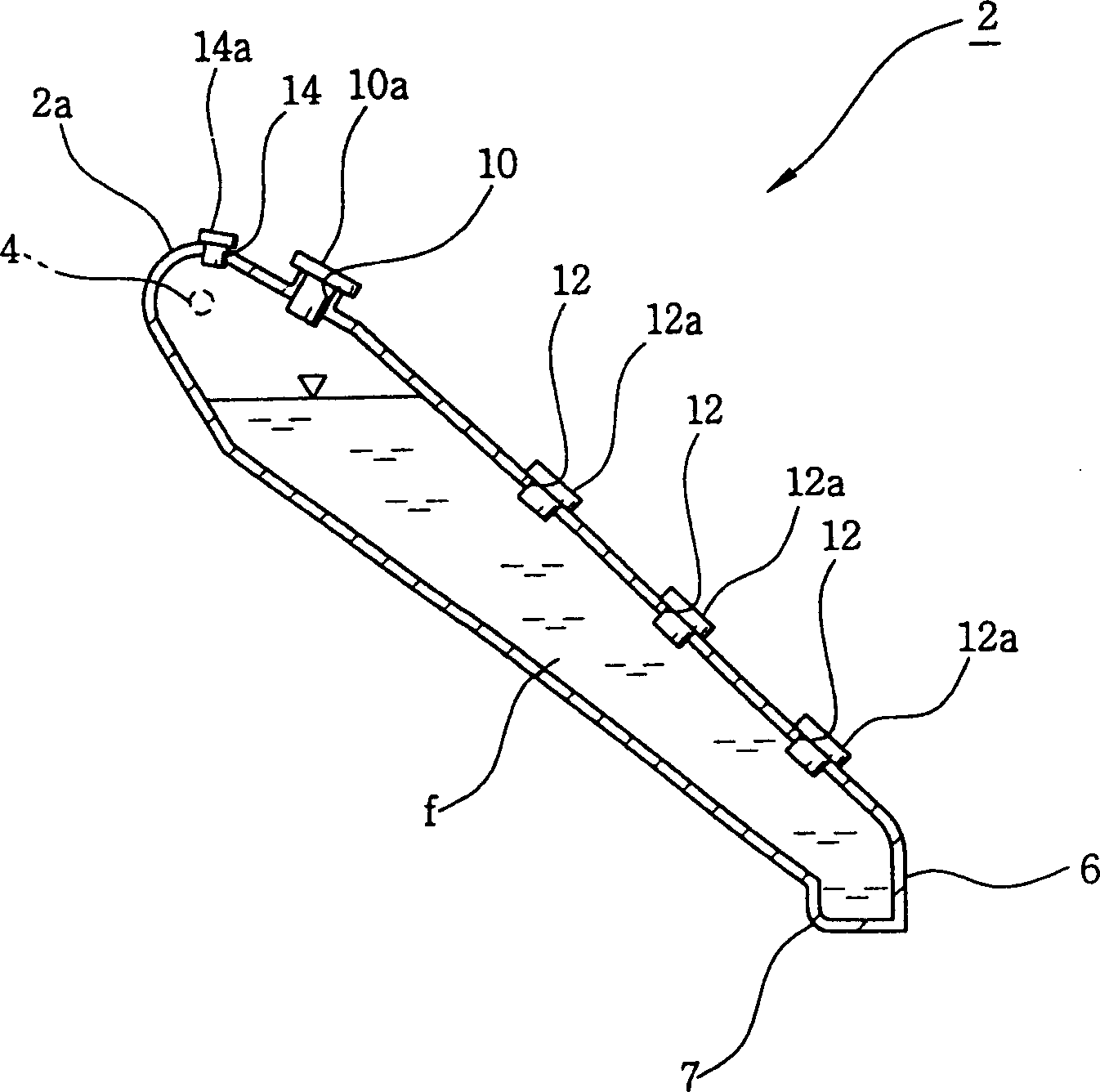

[0046] figure 2 and image 3 The shown streamlined automatic opening / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com