Method for removing and recovering reaction monomer

A vinylidene chloride, unreacted technology, applied in the field of vinylidene chloride-based resin slurry, can solve problems such as difficulty, temperature and separation tank temperature drop, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

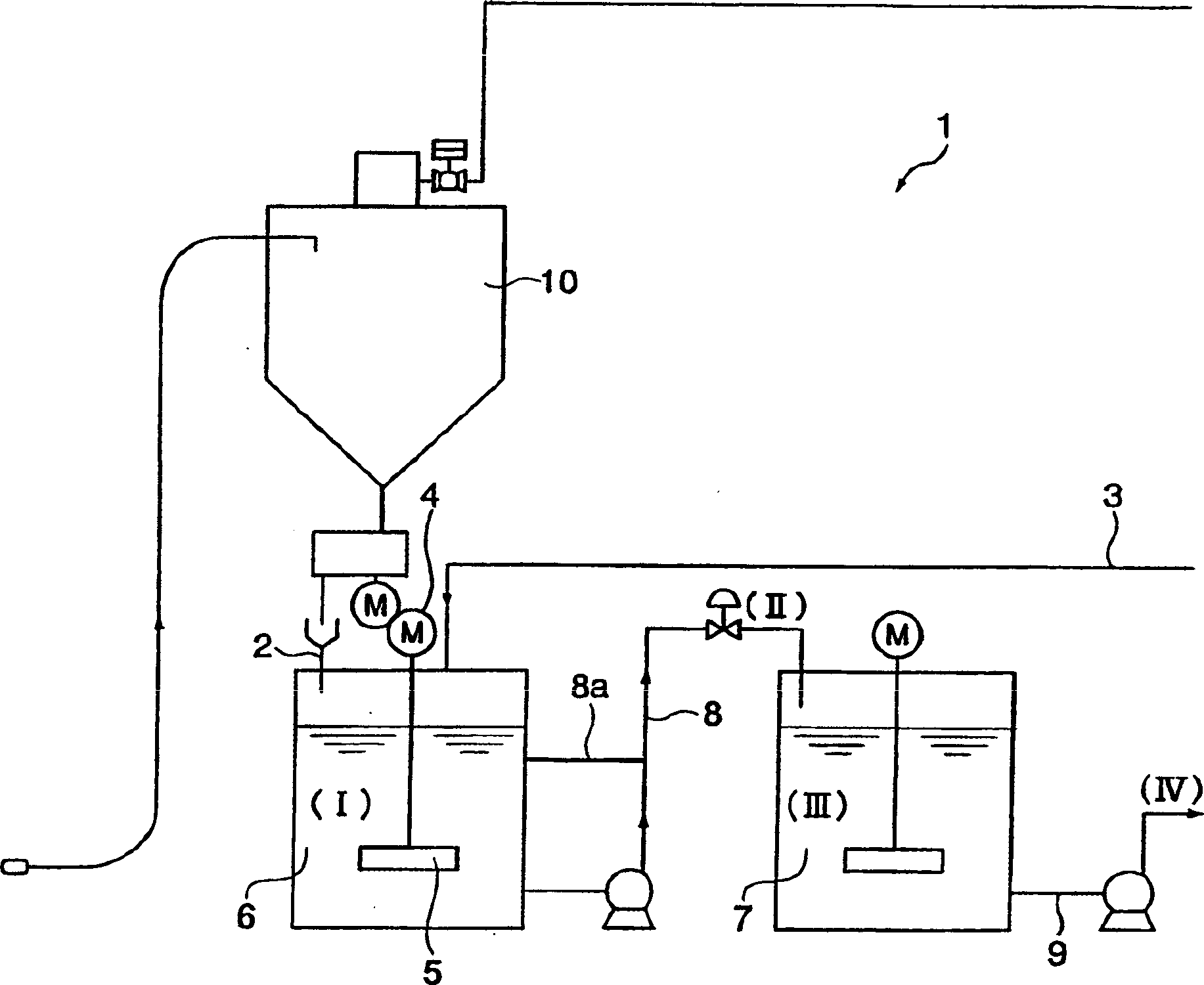

Image

Examples

Embodiment 1

[0085] polymerization

[0086] In a stainless steel polymerization vessel with an internal volume of 150 liters, 60 kg of deionized water in which 50 g of methylcellulose was dissolved was added as a suspending agent, and 41 kg of vinylidene chloride monomer and 9 kg of vinyl chloride monomer were thrown into it under stirring. and 100 g of isopropyl peroxydicarbonate as a polymerization initiator. While stirring the mixture, the temperature was raised to 45°C to start polymerization. Then, the polymerization was continued for 30 hours while continuously raising the temperature to 55° C. to obtain a polymer slurry containing unreacted monomers.

[0087] mixing of steam

[0088] Next, install a steam mixer on the way from the bottom of the polymerization vessel to the unreacted monomer removal vessel to mix the steam and increase the temperature of the slurry to 80-90°C.

[0089] stress reliever

[0090] Then, the slurry was transferred to an unreacted monomer removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com