Energy-saving long-life electric fan and its manufacture method

An electric fan and long-life technology, which is applied in the direction of non-variable pumps, pump devices, machines/engines, etc., can solve the problems of low working efficiency and long service life of fans, and achieve increased strength, rigidity and working efficiency High, the effect of output power improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

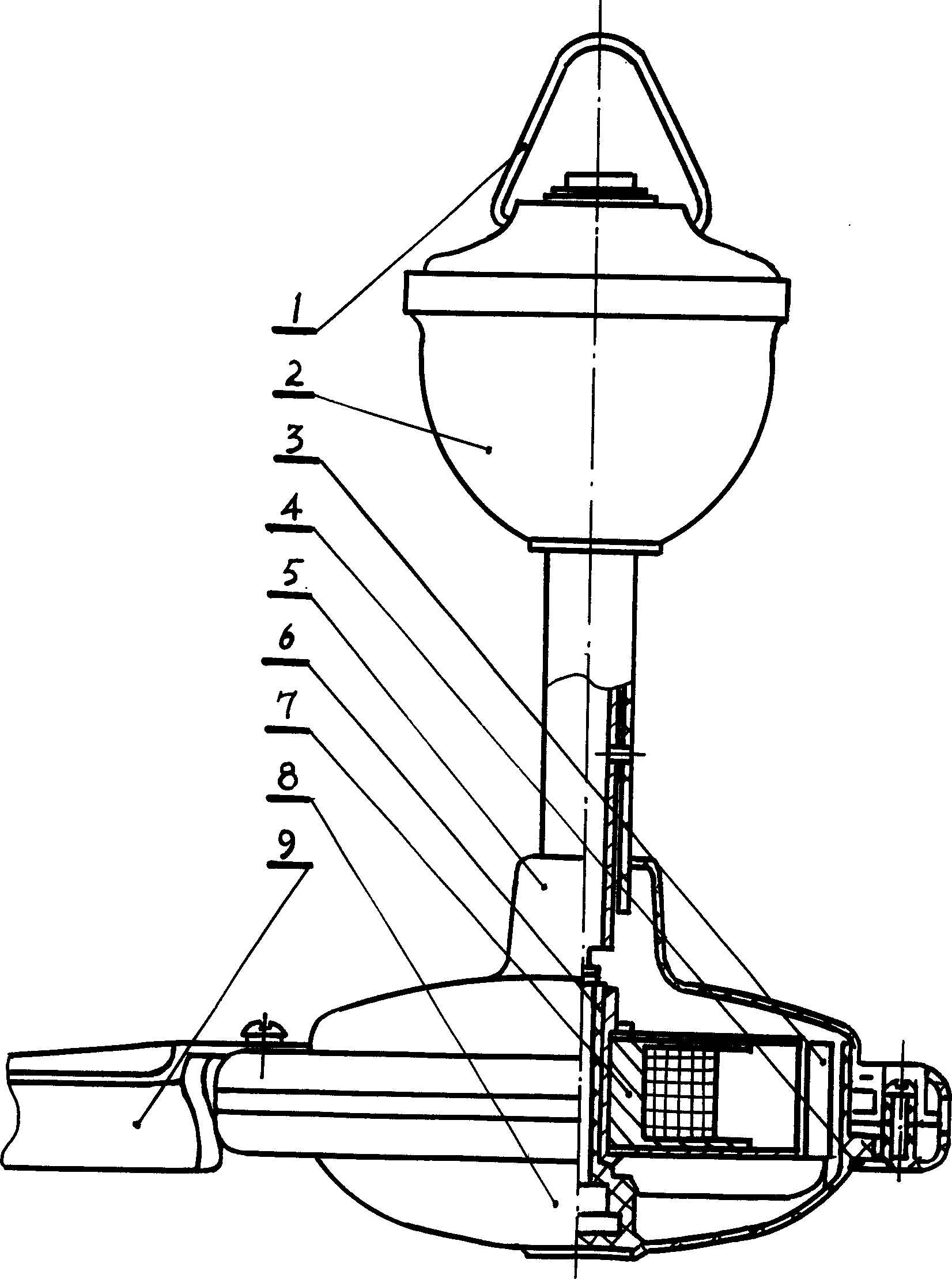

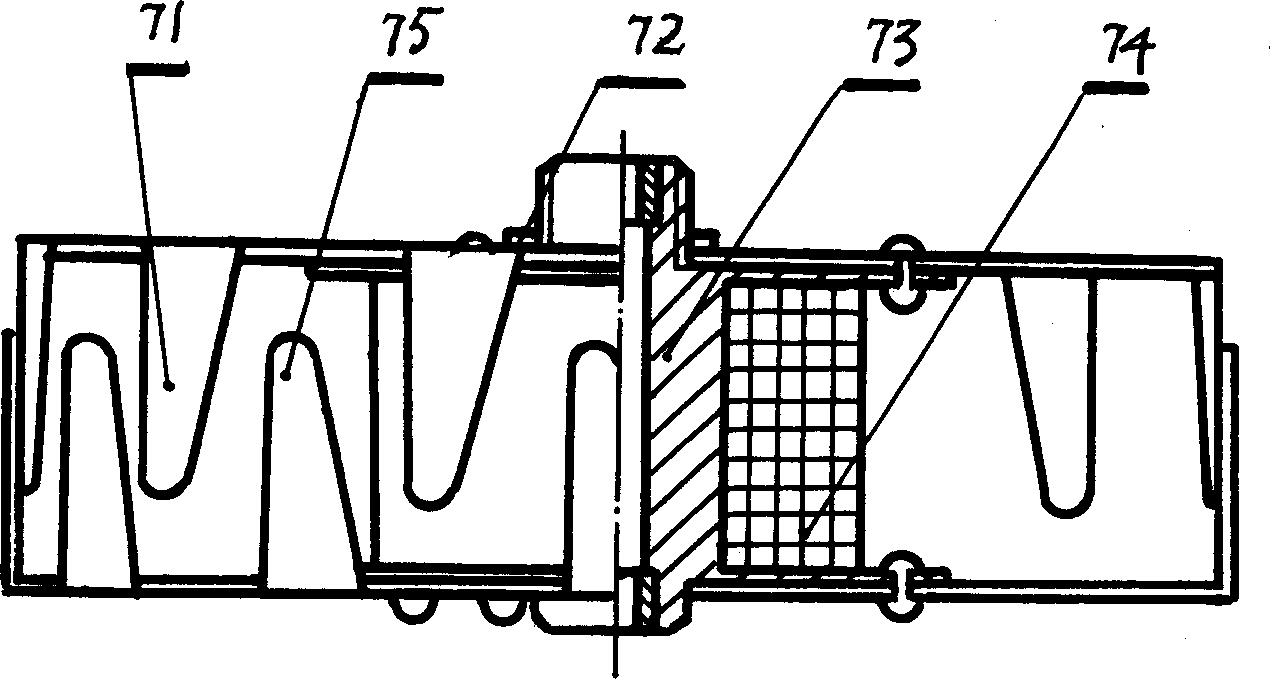

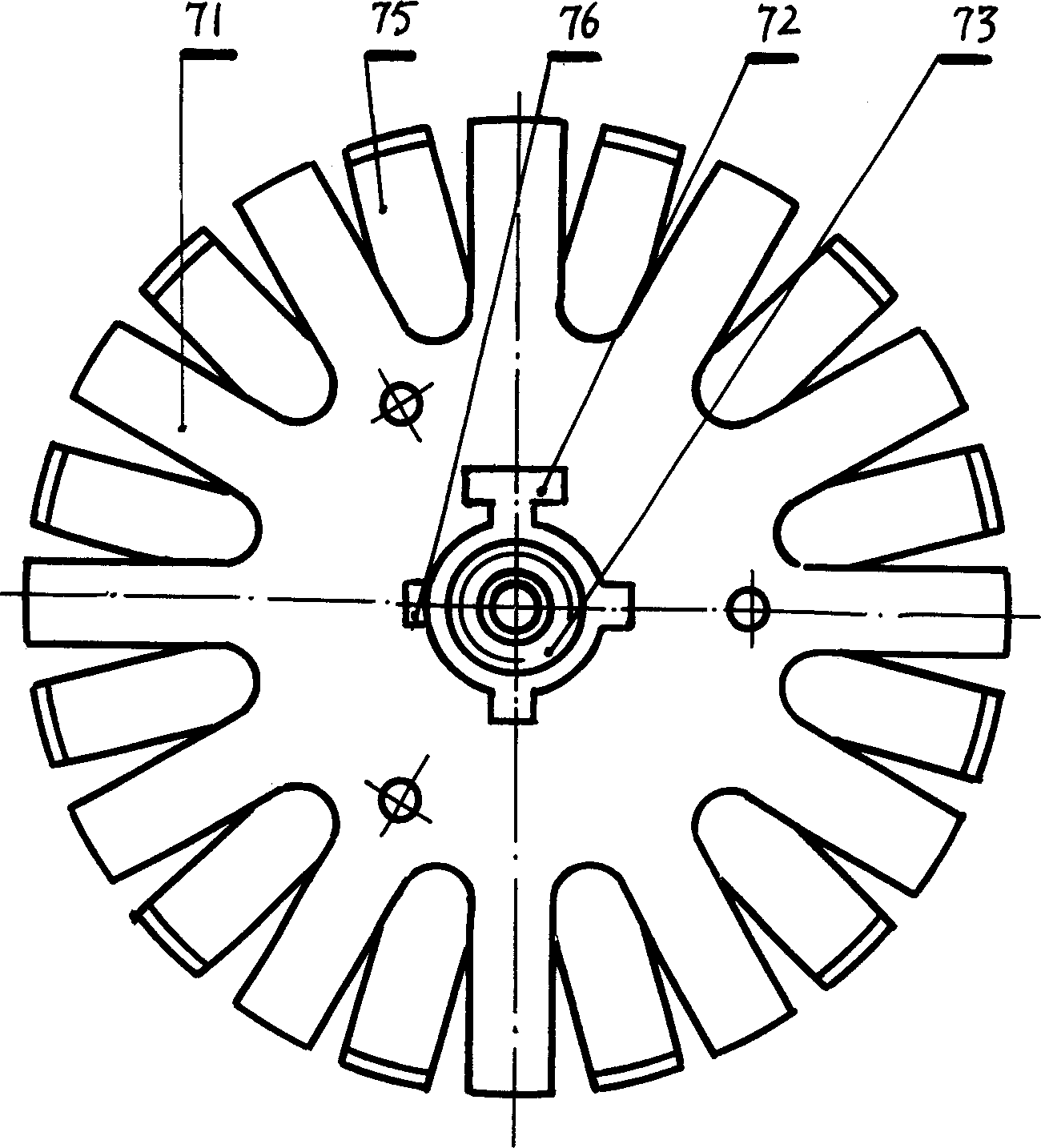

[0011] as attached Figure 1-10 As shown, the energy-saving and long-life electric fan includes a lower end cover 8 and an upper end cover 5 fixed thereon, an armature assembly 7 installed in the upper end cover 5 and the lower end cover 8 and fixed on the main shaft 6, and an armature assembly 7 fixed on the lower end cover 8 Magnetic sheet 3, starter box assembly 2 and suspension ring 1 fixed on the main shaft 6, fan blade 9 fixed on the outer rotor. The armature assembly 7 includes a wire frame core 73 , a coil 74 wound on the wire frame core 73 , and an upper claw pole 71 and a lower claw pole 75 fixed on the wire frame core 73 . The wire frame iron core 73 is composed of an iron core 733 , an upper end plate 731 fixed on the iron core 733 and a lower end plate 732 to form a part. There is an integrated bearing screw on the iron core 733 . The upper and lower ends of the iron core 733 are equipped with oil-im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com