Two-dimensional microvibration optical fibre test system and method

An optical fiber detection and two-dimensional optical fiber technology, which is applied to measurement devices, optical devices, image data processing, etc., can solve the problems of complex receiving equipment, low sensitivity, and inconvenient use, and achieve the effect of simple manufacturing and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

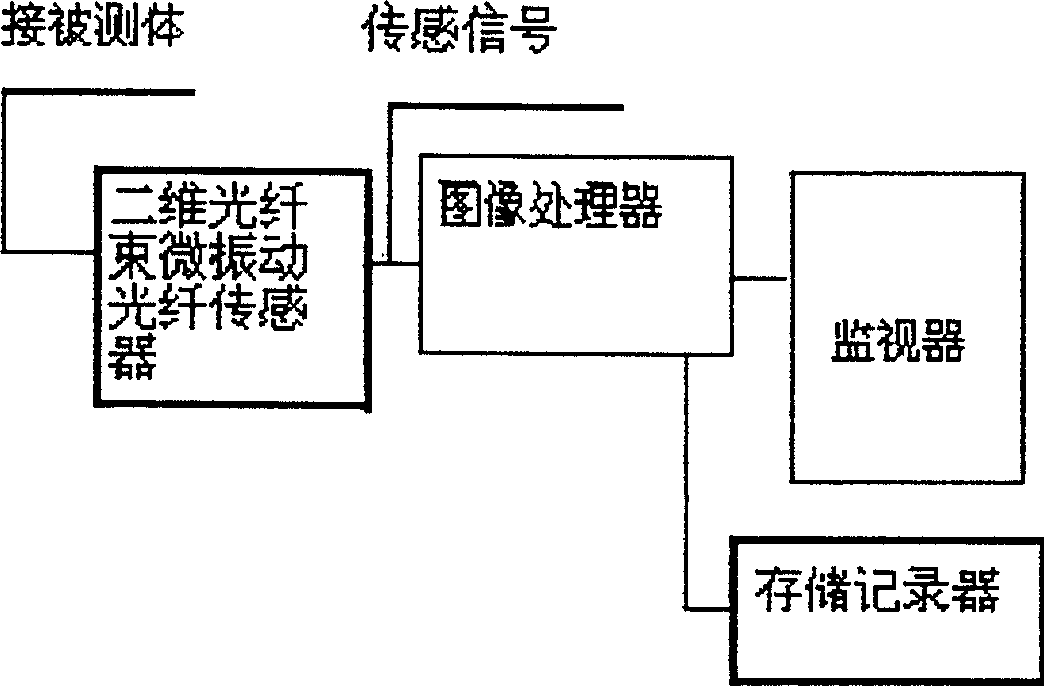

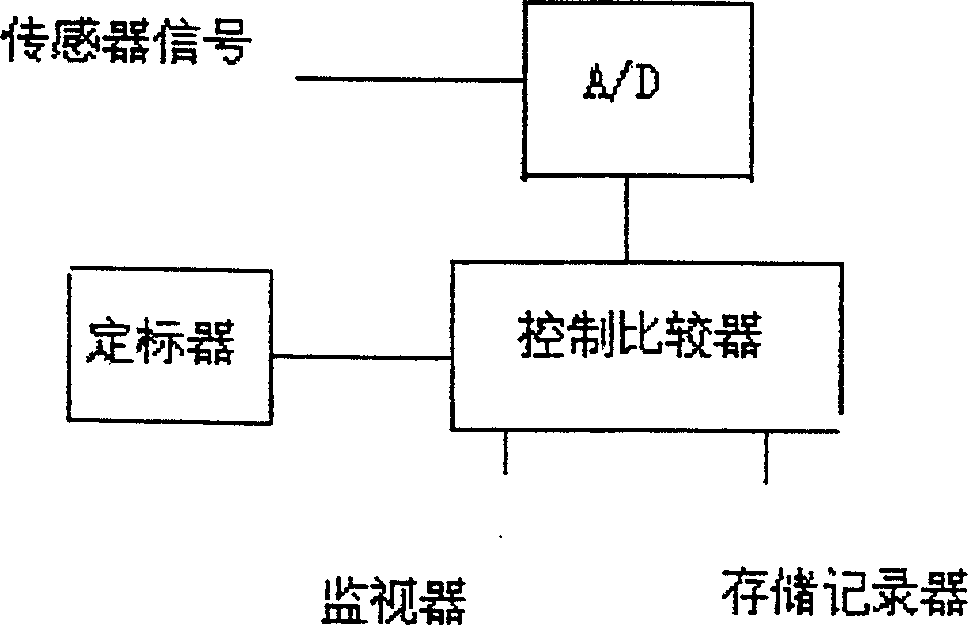

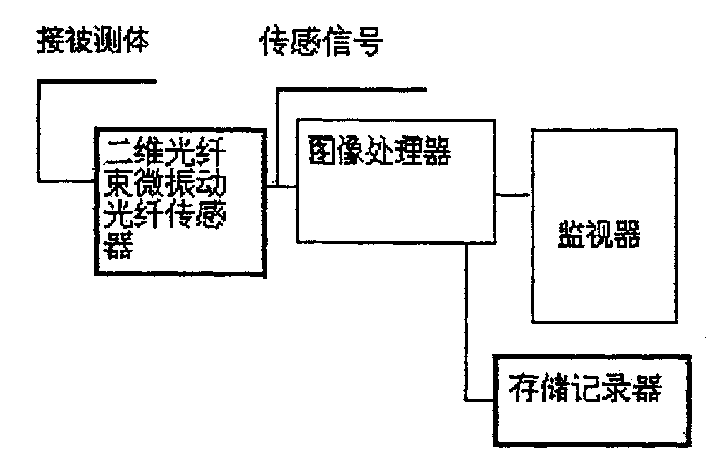

[0012] According to attached figure 1 In the two-dimensional micro-vibration optical fiber detection system, the two-dimensional optical fiber bundle micro-vibration optical fiber sensor placed on the measured object outputs the sensing signal to the image processor, and the image processor compares the sensing signal with the set standard signal for processing Then output to the monitor and memory recorder.

[0013] Install the two-dimensional optical fiber bundle micro-vibration optical fiber sensor on the vibrating body to be detected, and input the signal to image processing through the two-dimensional micro-vibration optical fiber sensor, and the quantitative signal after image processing is sent to the monitor and storage recorder, when the vibrating body When the vibration frequency of the fiber is close to the natural frequency of the fiber, the fiber will resonate, and it can be clearly seen on the monitor that the above-mentioned light spots will change with the ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com