Double bottom braze welding method

A brazing and heating head technology, applied in welding equipment, electric heating devices, metal processing equipment, etc., can solve the problems of complex equipment, difficult operation, energy waste, etc., and achieve the effect of simple equipment, easy control and less line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

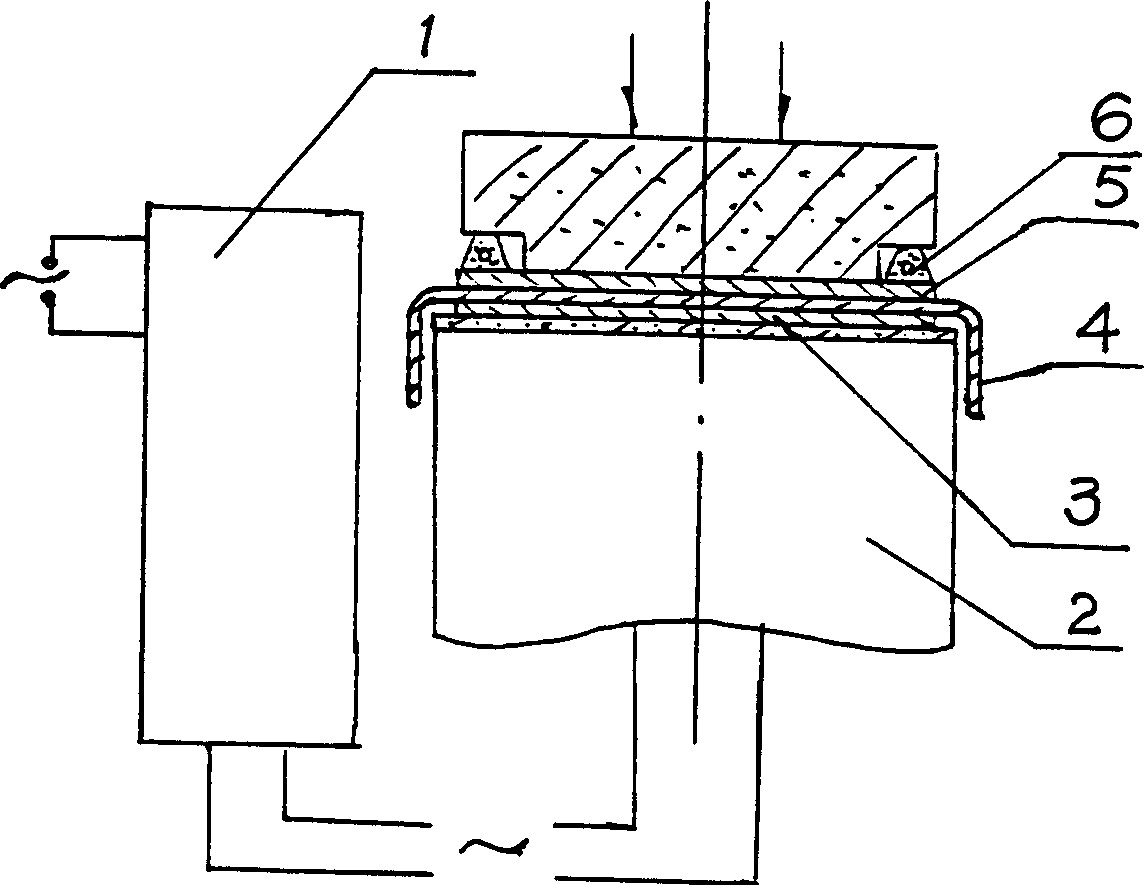

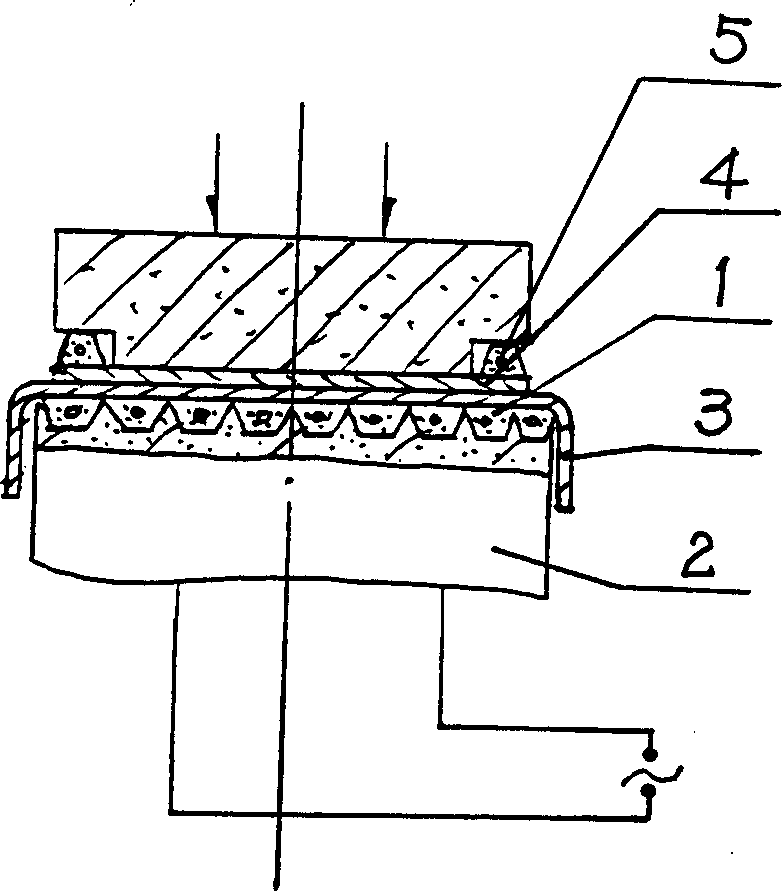

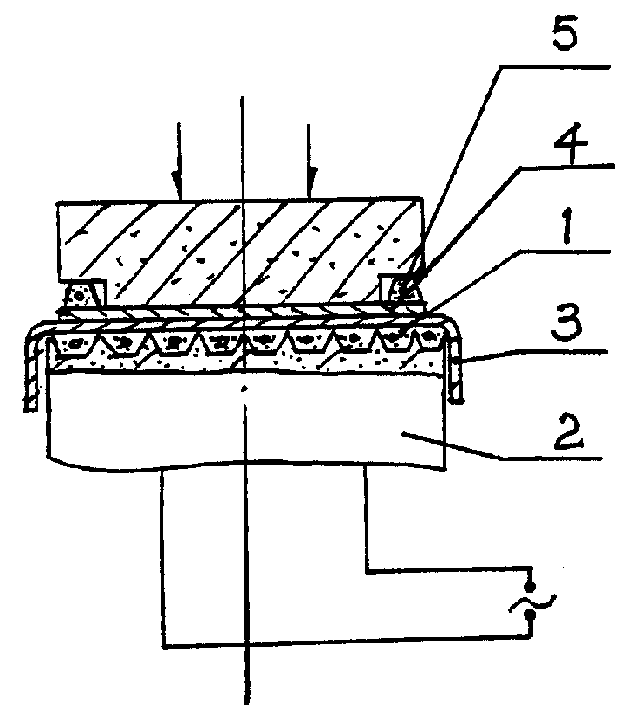

[0014] like figure 2 As shown, the multiple bottom brazing method of the present invention uses a plurality of electric heating tubes 1 to be combined and installed on the support base 2 to form a heating head. The flux between 4 and 5 is melted and then welded together by cooling.

[0015] In the method of the present invention, the combination of electric heating tubes can be a circular heating head composed of multiple ring-shaped electric heating tubes with different diameters, or a square heating head composed of multiple straight electric heating tubes arranged side by side according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com