Method of detecting residual oil saturation using single well chemical tracer

A chemical tracer and tracer technology, which is applied in the direction of using chemical indicators for analysis, geophysical measurement, instruments, etc., can solve problems such as unaffordable economy, error in saturation interpretation results, uncertainty about the amount of remaining oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiment of the invention

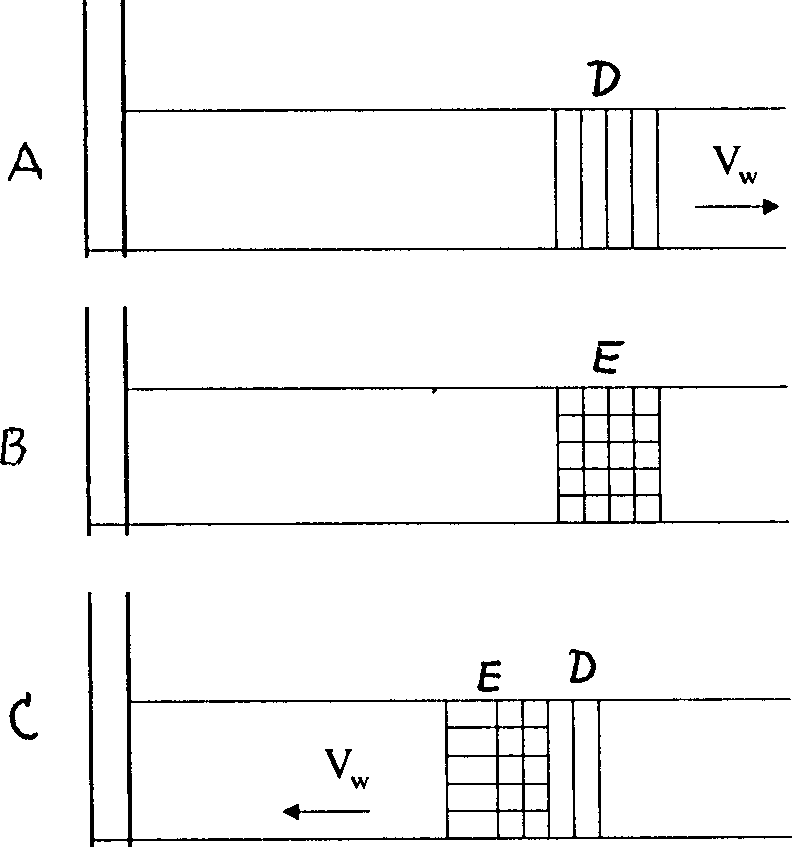

[0040] The present invention adopts single well chemical tracer to measure the method for remaining oil saturation and has following steps:

[0041] 1) Inject the first original tracer slug solution into the oil layer, and at the same time inject the replacement tracer to form the first formation brine solution slug. The first original tracer uses ethyl acetate or propyl acetate or propyl formate , the concentration in brine is 0.1--2.0%. The tracer can use industrial chemical raw materials, which can contain ethanol or propanol, and the replacement tracer can use methanol or butanol;

[0042] 2) Reinject the second original tracer of chemical ester different from the chemical composition of the tracer used in the first slug to form the second saline solution slug. For example, ethyl acetate is used for the first original tracer, and ethyl acetate is used for the second The original tracer uses propyl acetate or propyl formate, and vice ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com