Disk type motor

A disk-shaped and rotor technology, applied in the field of disk-shaped motors, can solve the problems of inability to utilize the excitation force of the stator, large self-excited magnetism, and high manufacturing costs, and achieve the goal of improving power saving effects, improving heat resistance, and reducing material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

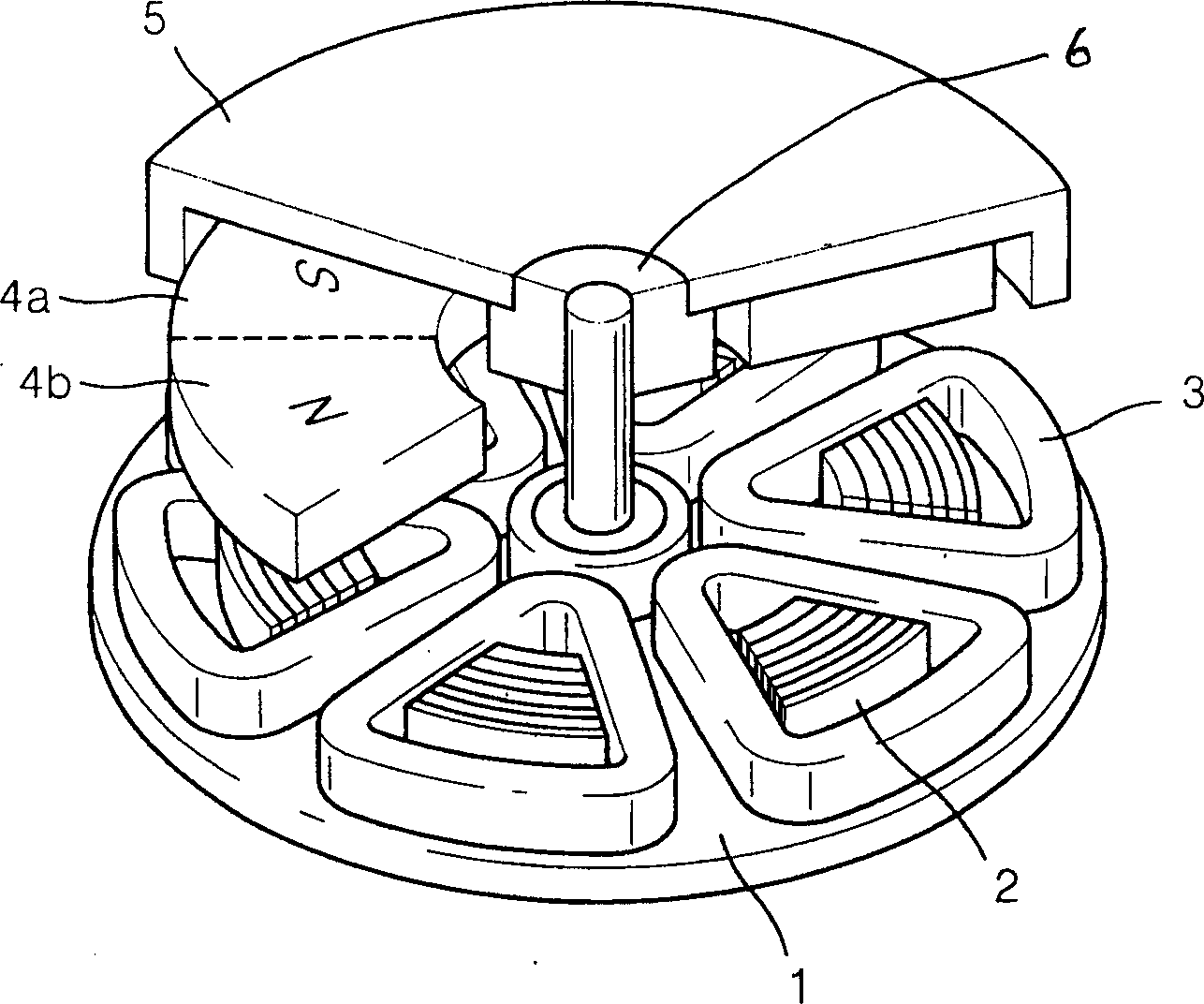

[0025] The disk motor of the present invention will be described below with reference to the drawings.

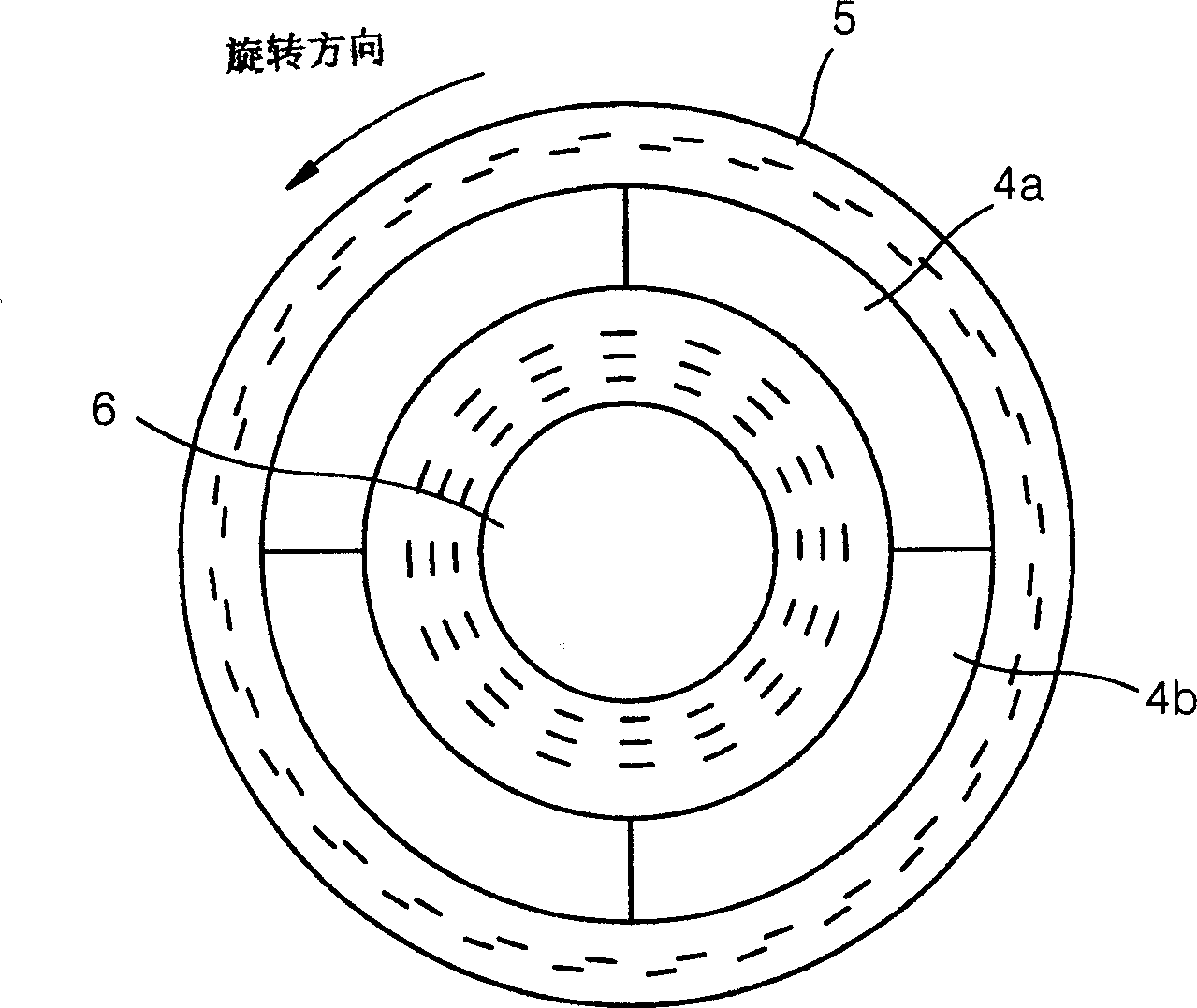

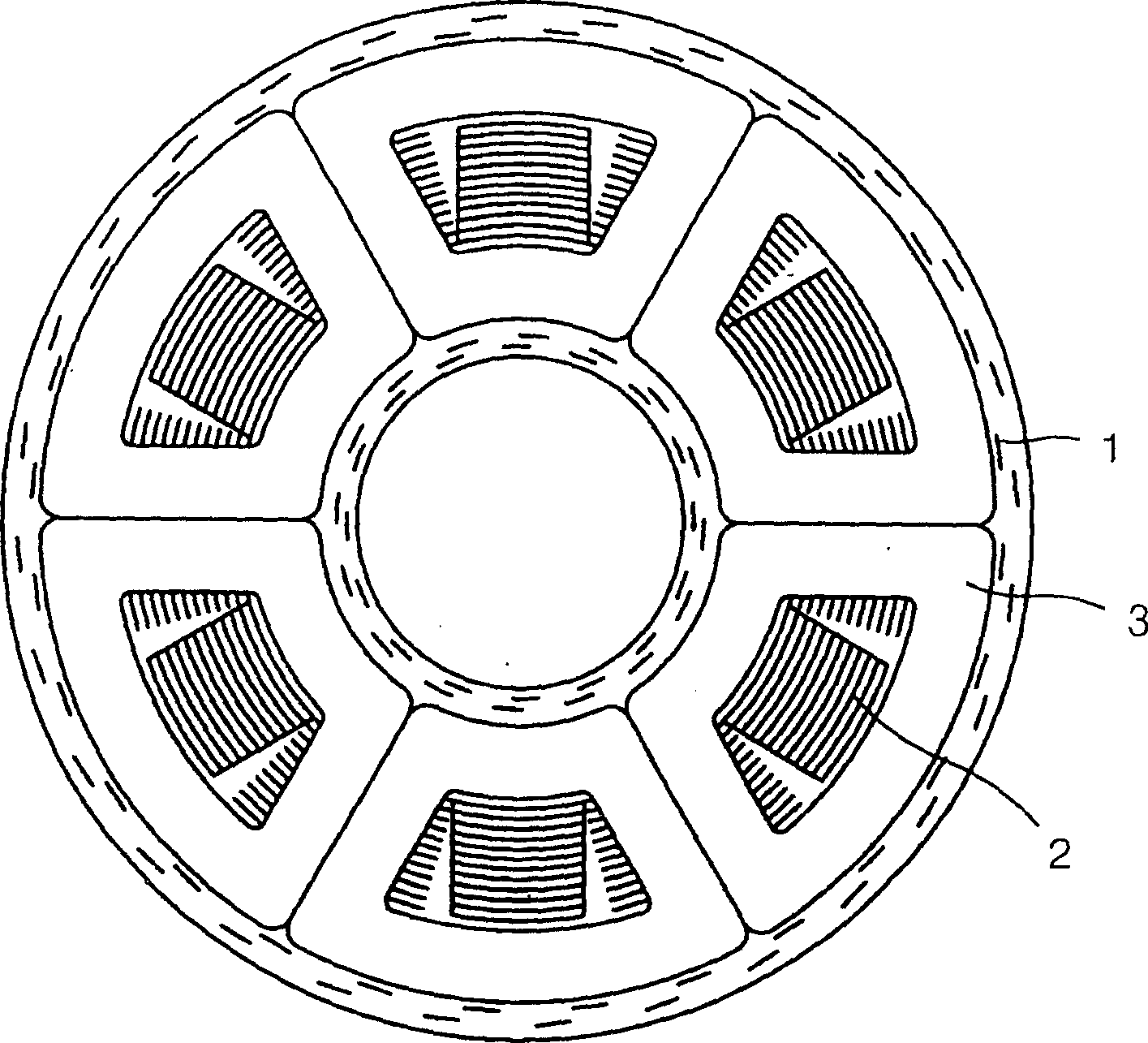

[0026] Such as Figure 4a As shown, the disc motor of the present invention comprises a salient pole iron core 2 with a certain length in the direction of the drive shaft, and a stator 1 that is wound with a winding 3 on the iron core 2 and plays an electromagnetic role, and is perpendicular to the center of the stator 1. Shaft 6 is provided, located in the facing direction of the stator 1, and has a certain distance to form at least one pair of permanent magnets for S pole 4a and N pole 4b excitation; a circular rotor 18 of salient pole iron 17 is installed between the permanent magnets, The shaft 6 etc. which transmit the rotational force of the said rotor 18 to a load are comprised.

[0027] Such as Figure 4b As shown, the rotor 18 of the disk motor of the present invention is centered on the shaft 6, forming a plurality of permanent magnets excited by S poles 16a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com