Fixed type self vibration damping difference flow sensor

A flow sensor, fixed technology, applied in the field of flow sensors, can solve problems such as limited ability to resist pipeline vibration, weak anti-interference ability of flow sensors, and large noise mixed into the output signal, achieving a large range, strong anti-interference, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

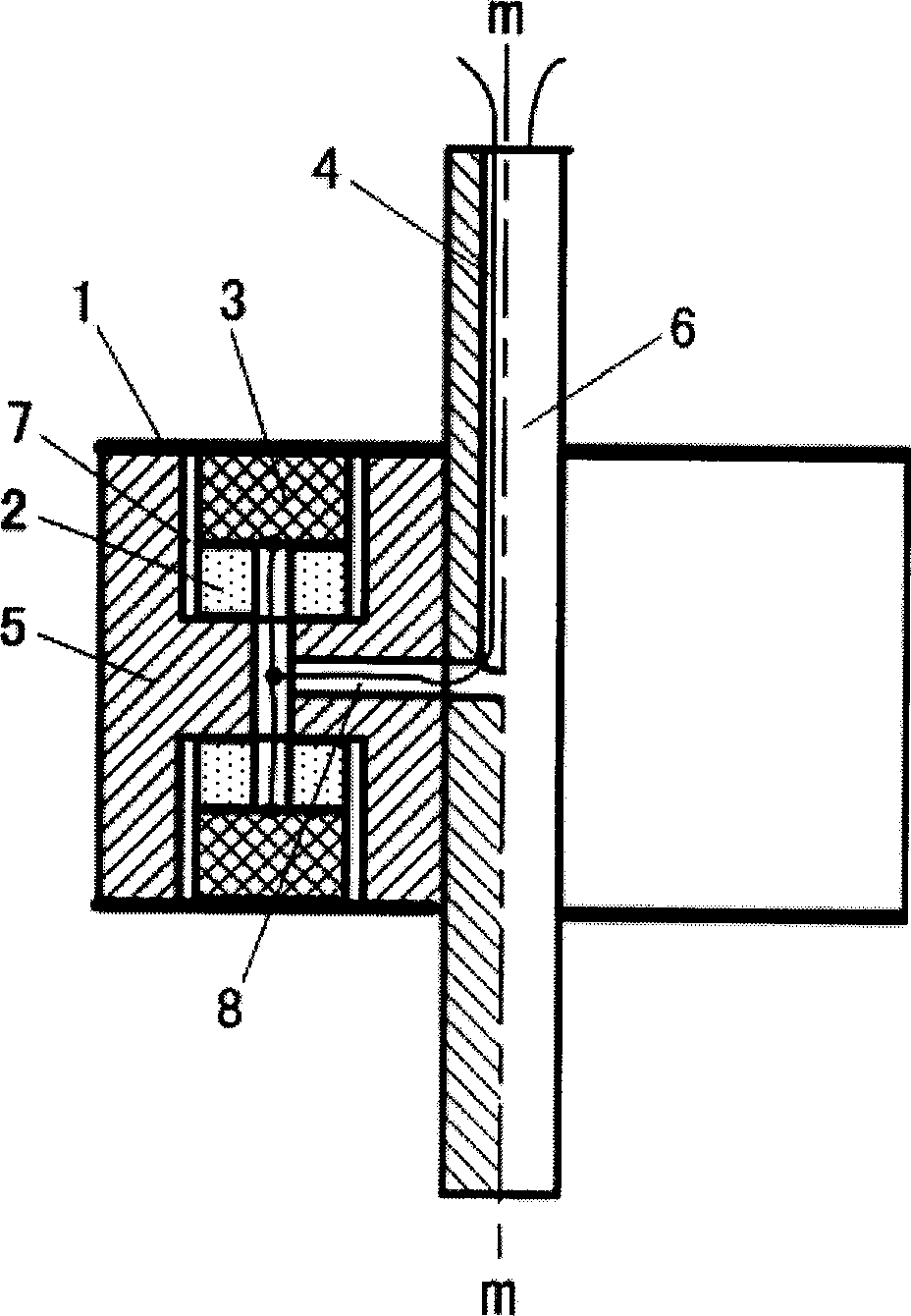

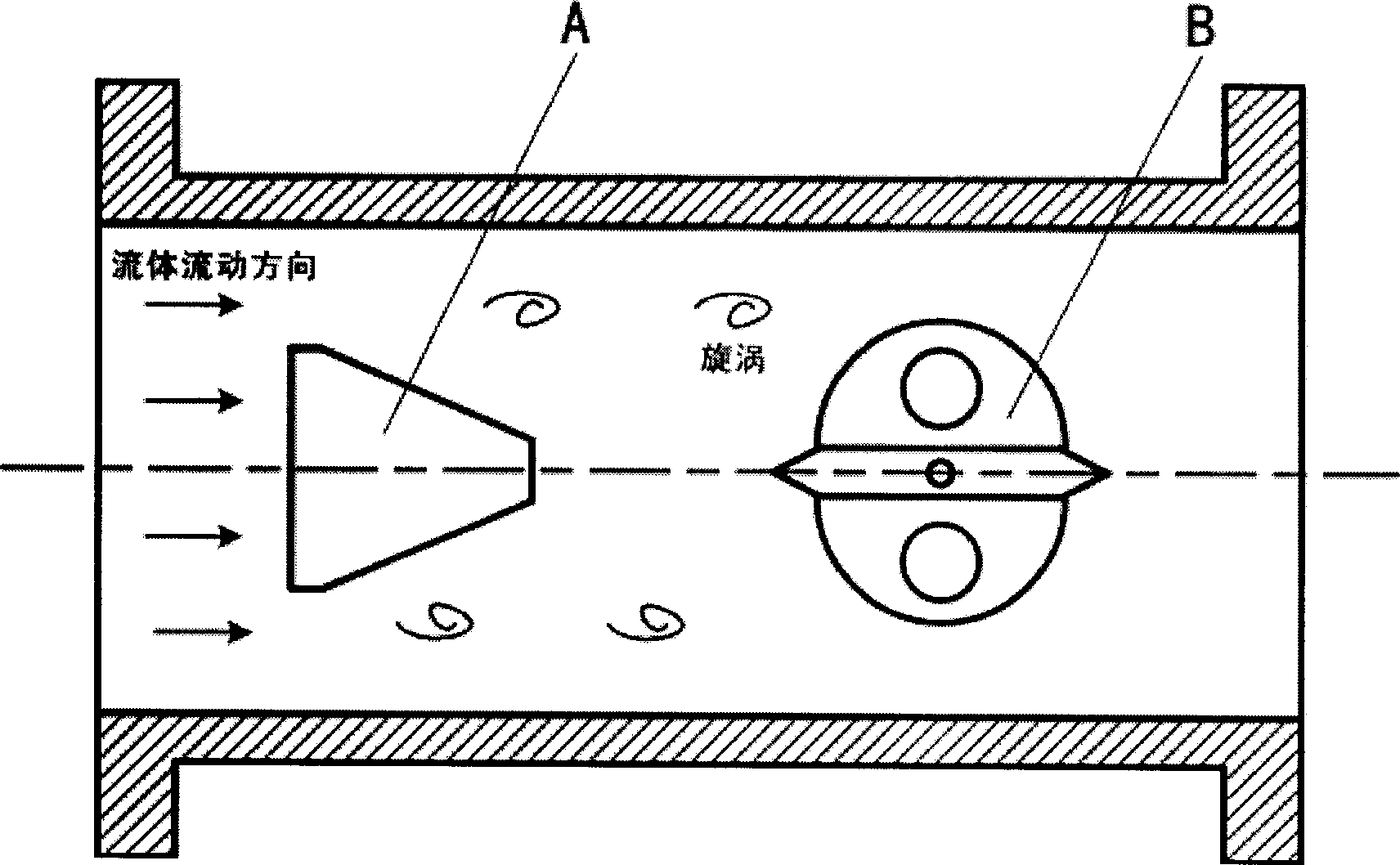

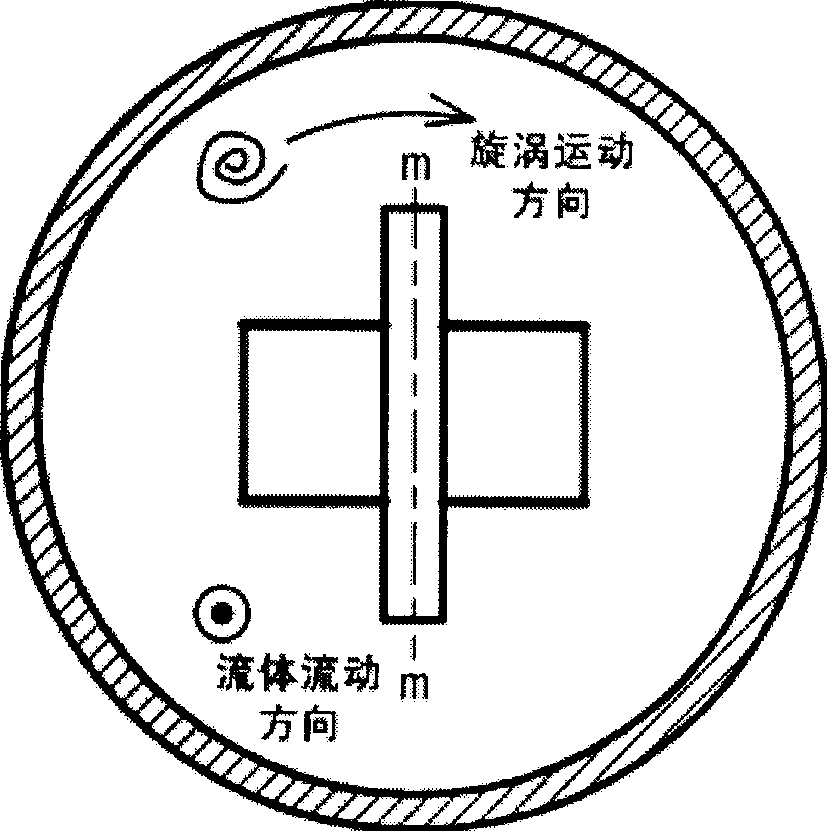

[0009] refer to figure 1 , the fixed self-damping flow sensor includes detection units symmetrically fixed on both sides of the plate 6, each detection unit includes a housing 5, in order to obtain a more stable signal, generally use a semi-cylindrical housing, the housing 5 has a m-m parallel through hole 7, there is a boss in the middle of the through hole 7 that divides the through hole into two symmetrical sections up and down. It is connected to the outlet hole 4, and the two ends of the through hole 7 are respectively sealed by elastic diaphragms 1. There are piezoelectric ceramic sheets 3 and ring-shaped insulating ceramic blocks 2 in each interval, and one end of the piezoelectric ceramic sheet is connected to the elastic diaphragm 1. Welding, the insulating ceramic block 2 is sandwiched between the boss and the piezoelectric ceramic sheet, and there is a gap between the periphery of the piezoelectric ceramic sheet 3 and the insulating ceramic block 2 and the wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com