Dry-type spiral vacuum pump

A vacuum pump and screw technology, applied in the field of dry screw vacuum pump, can solve the problems of reducing the performance of the vacuum pump, increasing the gap leakage, prone to failure, etc., to eliminate the accident of rotor contact, prevent exhaust pollution, and suppress exhaust temperature. Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

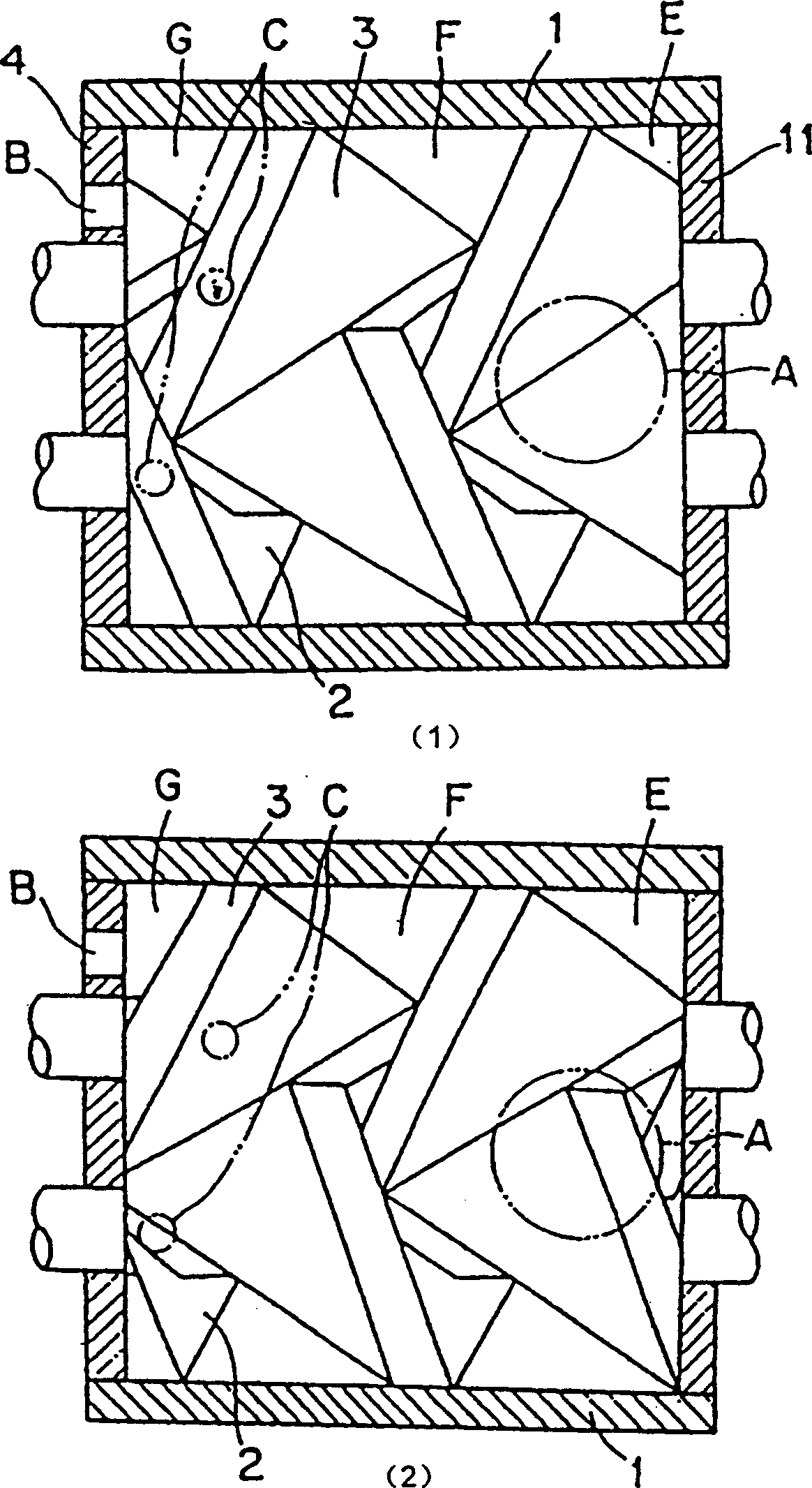

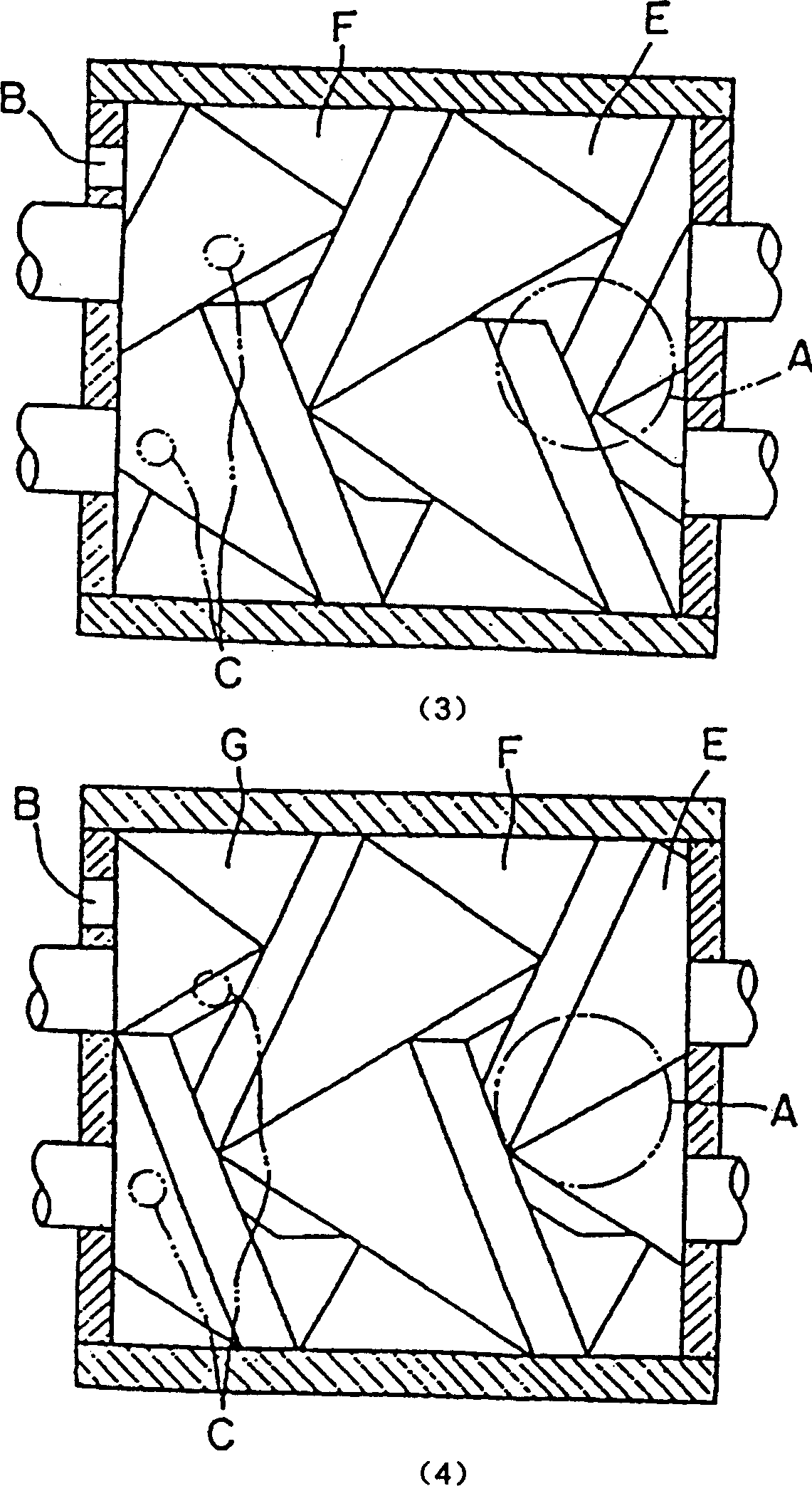

[0024] Embodiments of the present invention will be described with reference to the drawings.

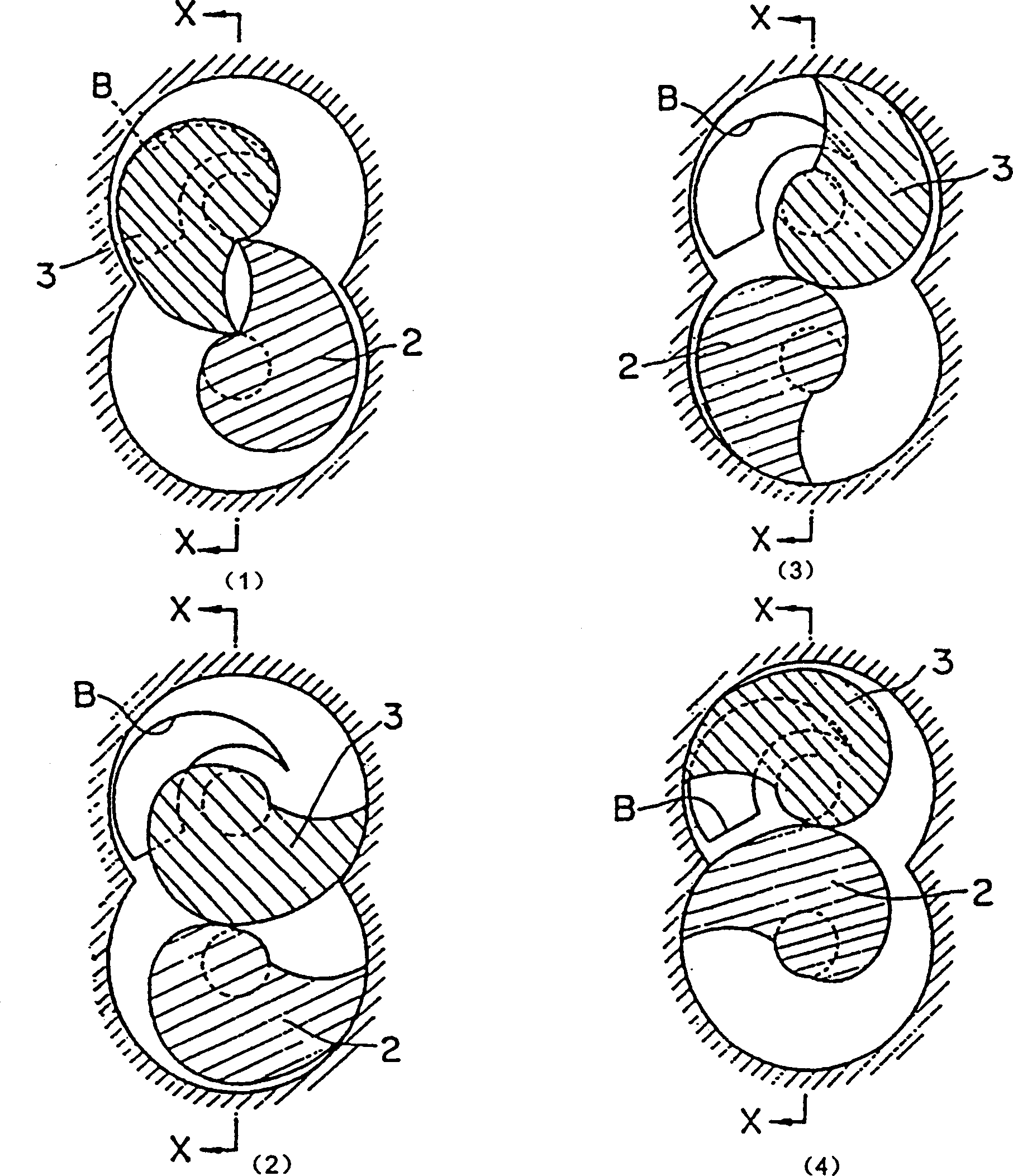

[0025] Fig. 3 shows a helical screw vacuum pump, the pump body 1 contains rotors 2, 3 with right helical patterns and left helical patterns.

[0026] Reference numeral 4 is a side box A containing the space of the above-mentioned threaded portion and constituting a partition wall on the discharge side.

[0027] Bearing bracket 5 is contained on the side case A (4), and bearing bracket 5 is equipped with bearing 6 for supporting the rotating shafts 2a and 3a of the discharge sides of rotors 2 and 3, and a shaft seal 7 for sealing shafts 2a and 3a.

[0028] Motor support 8 is housed on the left side end face of side box A (4). Reference numeral 9 denotes a motor shaft, which transmits the rotational driving force to the rotor 2 via a shaft joint 10 .

[0029] The right end surface of the pump body 1 is equipped with a side box B (11) that accommodates the space for the spiral parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com