Chromatography device with negative pressure

A negative pressure layer and negative pressure technology, applied in ion exchange treatment devices, ion exchange regeneration, ion exchange, etc., can solve the problems of large energy consumption, long separation cycle, and low separation efficiency, and achieve less solvent and short cycle , high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

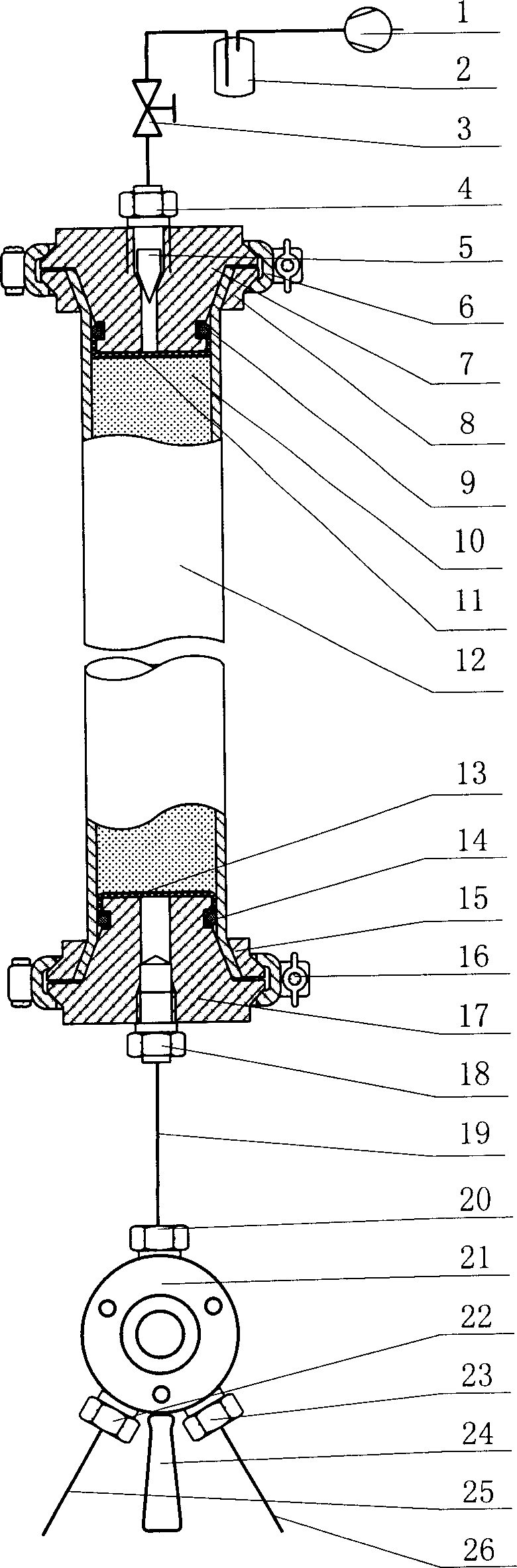

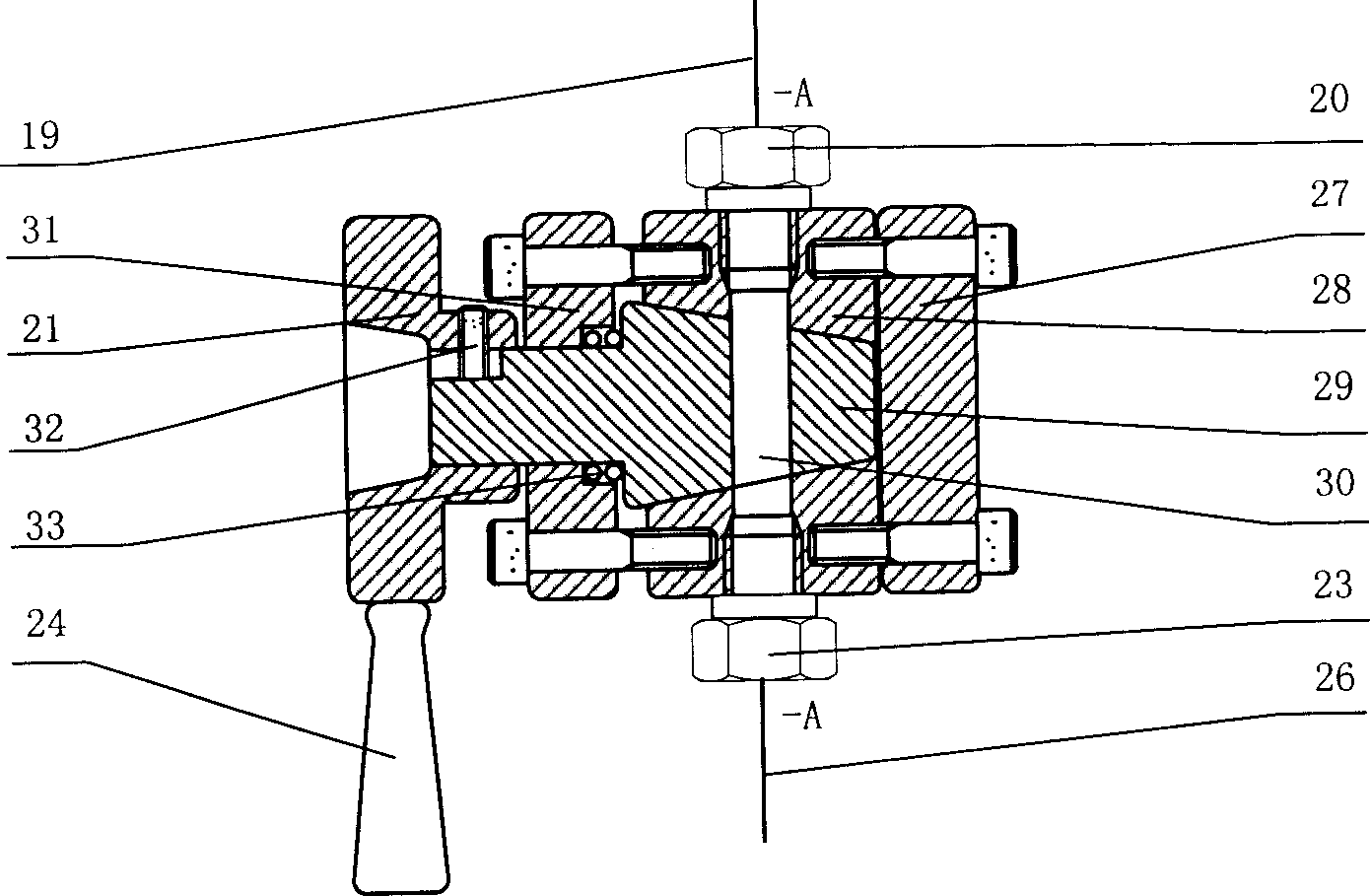

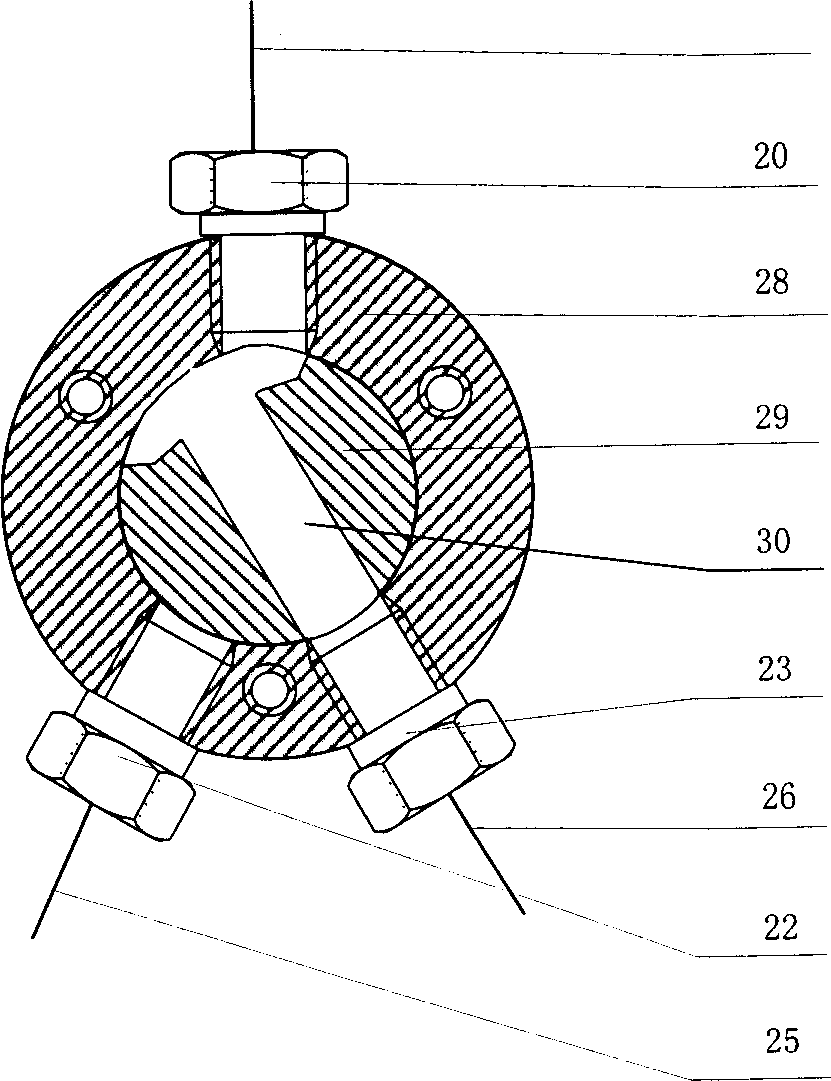

[0012] Depend on figure 1 , figure 2 It can be seen that the upper end of the cylinder 12 is provided with a quick-opening tight lock 6. The upper conical head 7 and the upper conical ferrule 8 are engaged with each other, and the upper part of the upper conical head 7 is provided with a negative pressure interface 4. Valve 3, vapor-liquid separator 2 is connected with negative pressure pump 1, check valve 5 is installed in the negative pressure interface 4 of upper conical head 7, filter screen 11 and filter screen snap ring 9 are arranged at the lower part of upper conical head 7 , the lower end of the cylinder 12 is provided with a quick-opening lock 16 to lock the lower conical head 17 and the lower conical ferrule 15 to engage with each other, and the upper part of the lower conical head 17 is provided with a filter screen 13 and a filter sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com