Products producted by high temp pyrolysis

A high-temperature pyrolysis, product technology, applied in the fields of nanotechnology, inorganic chemistry, nanotechnology, etc. for materials and surface science, which can solve problems such as working range limitations, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

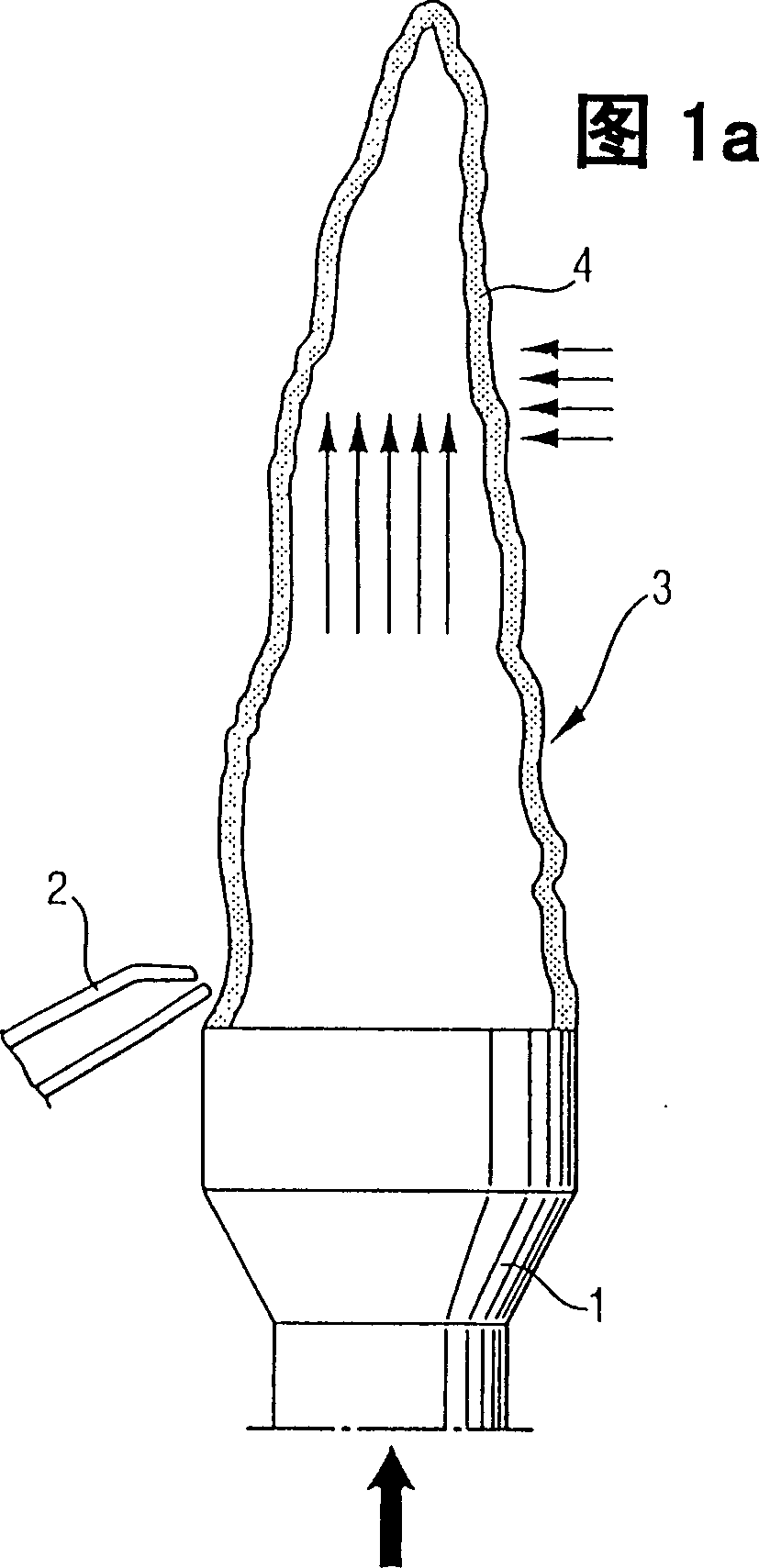

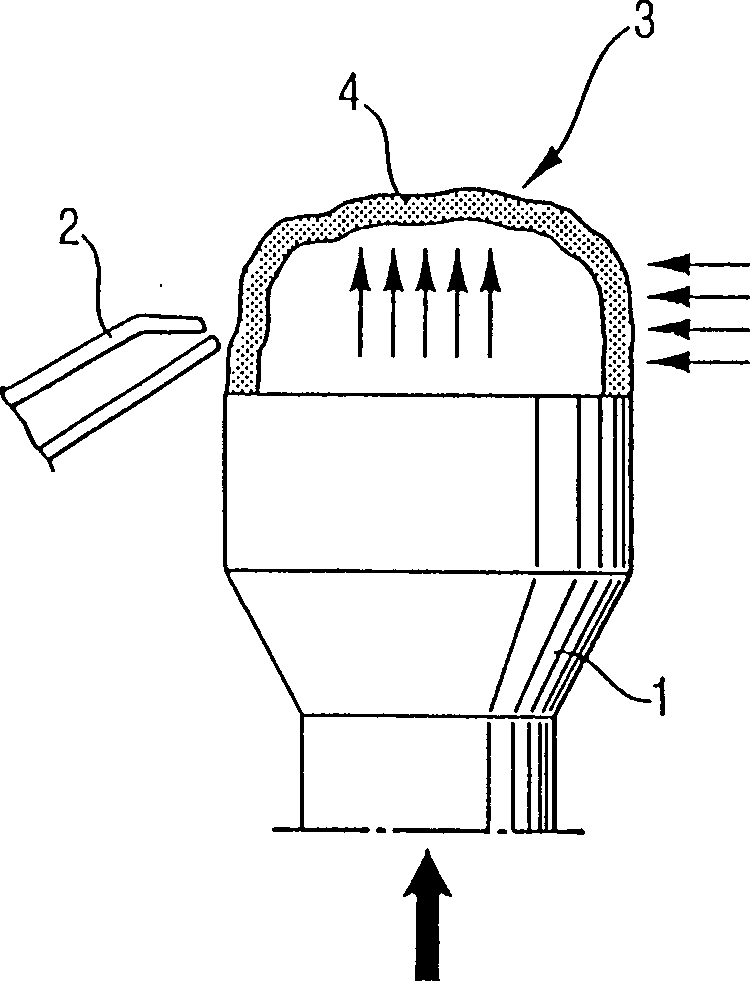

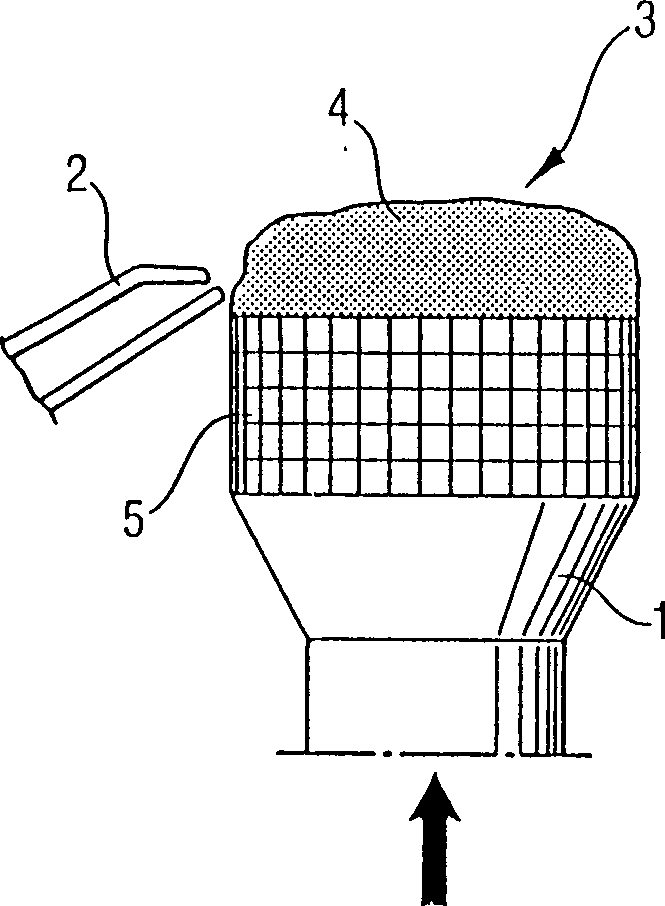

Image

Examples

example 1

[0061] SiCl in a hydrogen flame 4 Manufactured with a specific surface area of 100m 2 / g high temperature pyrolysis SiO 2 , when the outflow speed is 5m / s, the molded body 5 is used, while the molded body 5 is not used when the outflow speed is 40m / s.

[0062] When no shaped bodies were used, agglomerates were formed with an average of 9 primary particles per agglomerate ( FIG. 2 a ). Here, the average primary particle diameter is 19 nm (Fig. 2c). The distribution of both primary particle number and primary particle size is broadened by the different temperature-residence time histories traversed by individual particles. In this way, agglomerates with 3 to 15 primary particles occur, where the size of the primary particles is between 3 and 45 nm, the standard deviation of the primary particle size distribution being in this case σlog=1.9.

[0063] When using shaped bodies 5, the number of primary particles per agglomerate is reduced. About 70% of the particles exist as ...

example 2

[0065] SiCl in a hydrogen flame 4 Manufactured with a resulting specific surface area of 300m 2 / g of high-temperature silica, when the outflow velocity is 5m / s, a molded body is used, while when the outflow velocity is 40m / s, a molded body is not used.

[0066] When forming silica with a higher specific surface area, a trend similar to that of FIG. 1 at a smaller surface area can be seen. The average number of primary particles decreased from 22 to 7, while the range narrowed from 10 to 40 primary particles per agglomerate to 2 to 14 (Figs. 3a and 3b). With an almost identical average particle diameter of 10 nm, the primary particle size distribution is narrower with shaped bodies (σlog=1.3 versus σlog=1.6, FIG. 3 c ).

[0067] Both examples demonstrate that the size distribution of the agglomerates is also narrowed in the case of shaped bodies, since the size of the agglomerates is determined by the size of the primary particles, in particular by the number of primary pa...

example 3

[0069] In the hydrogen flame, when the outflow velocity is 5m / s, in the case of using the molded body 5, use SiCl 4 Manufacture of high temperature SiO 2 . Similar to Example 1 and Example 2, in this example high temperature SiO can also be obtained in water at pH 8 2 Narrow primary particle size distribution of the dispersion. The samples were dispersed in an ultrasonic bath for 5 minutes and measured with a submicron expanded laser diffraction spectrometer (model LS230) with proportional-integral-derivative (PIDS). The average agglomerate diameter in this case was 56 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap