Safety device for filling strainer

A safety device, technology of straightening machine, applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve the problems of reduced precision, damage to the weft straightening machine, loss of fabric maintenance costs, etc., and achieve deformation and loss. The effect of minimal, stable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

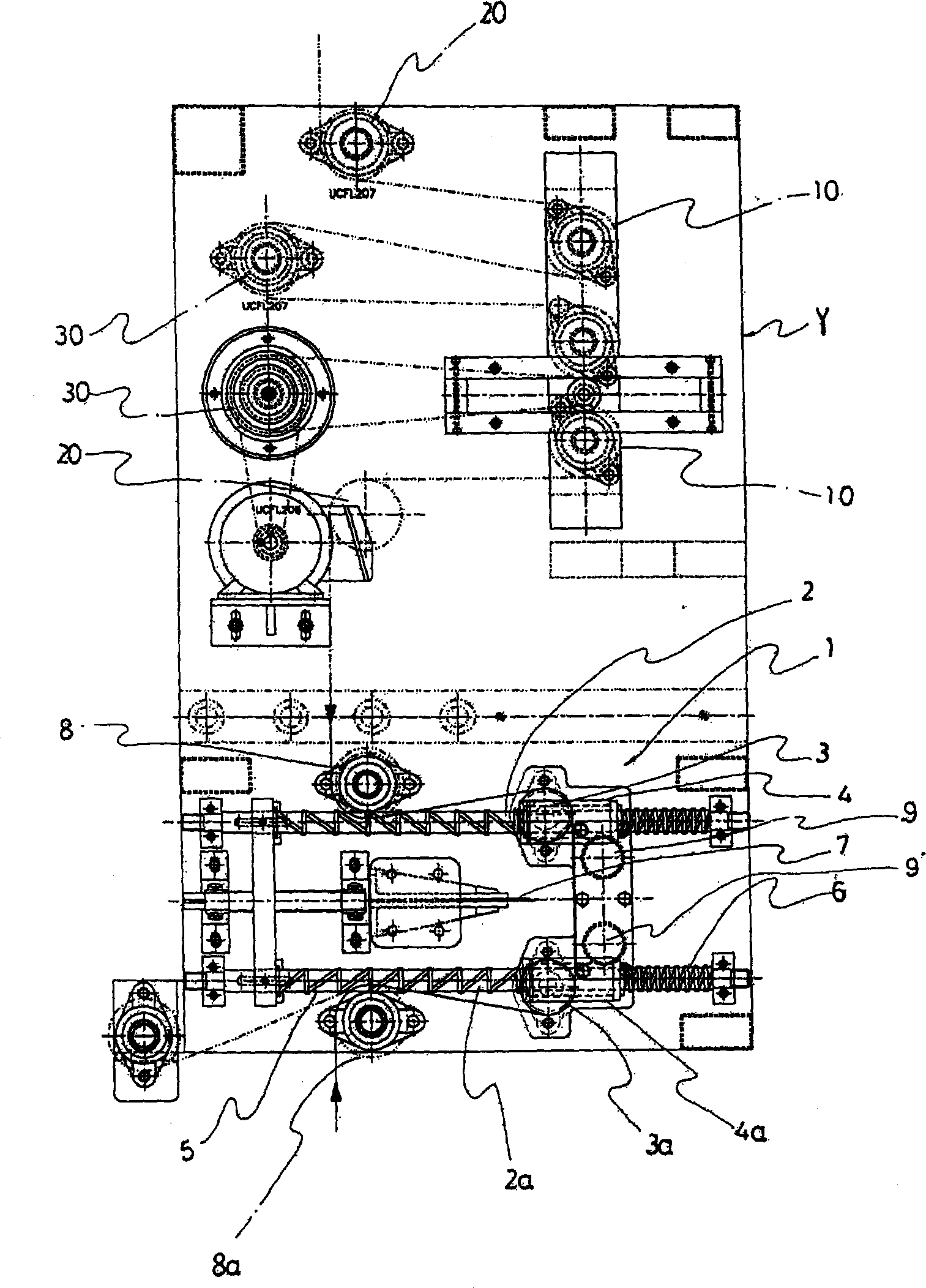

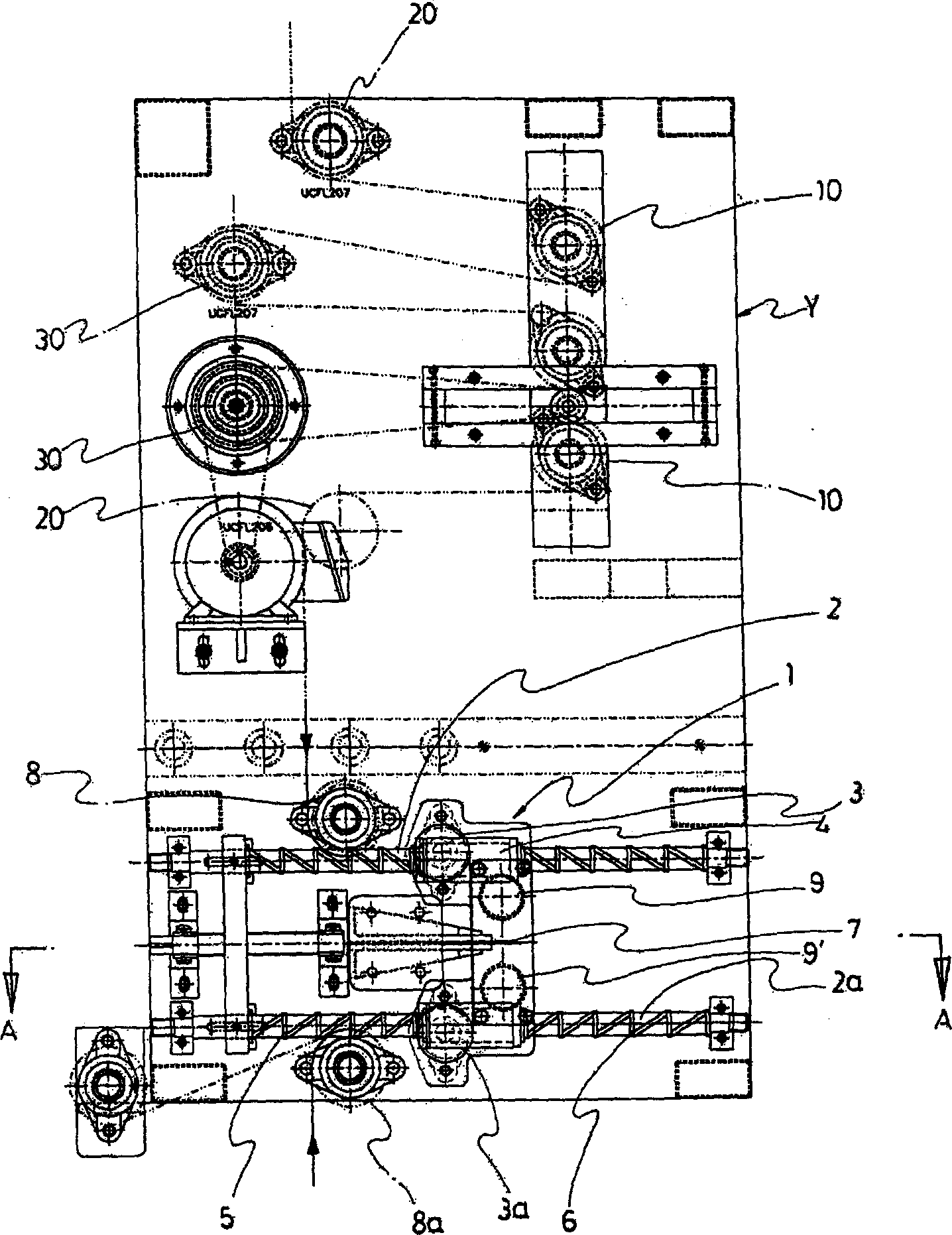

[0015] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

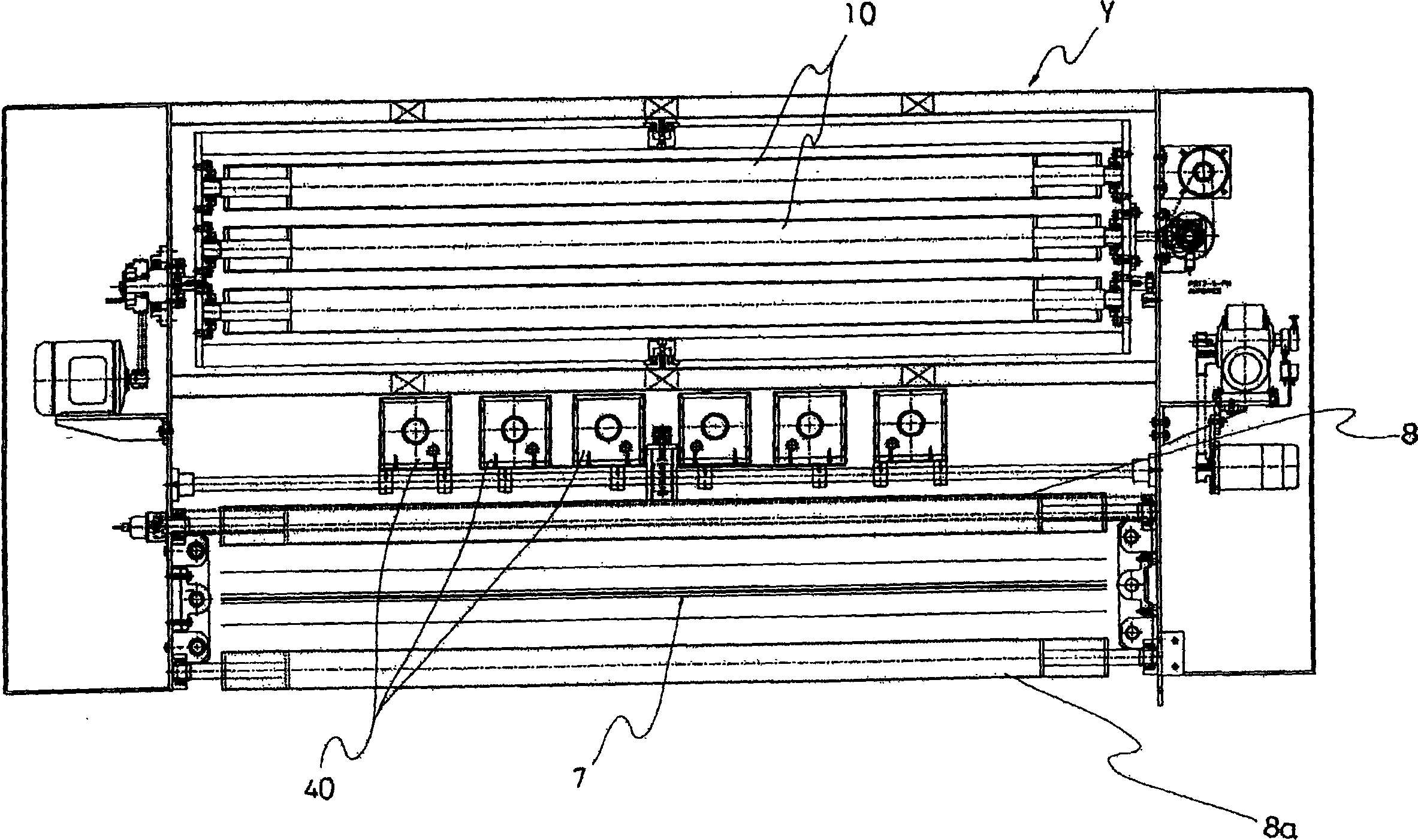

[0016] In a weft yarn straightening machine comprising a plurality of meander straightening rollers 10, a guide roller 20, a bending straightening roller 30 and a plurality of weft yarn sensors 40, the safety device 1 is installed inside the bottom side of the weft yarn straightening machine . Safety device 1 comprises: guide bar 2 and 2a, and this guide bar 2 and 2a are respectively fixedly installed on the upper part and the bottom of two frame (right frame and left frame) inner wall of weft yarn straightening machine body Y; Slider 4 and 4a, The sliders 4 and 4a are connected with the guide rods 2 and 2a for supporting the stretching rollers 3 and 3a; a strong compression spring 5 and a weak compression spring 6, which are mounted on the guide rods 2 and 6 The front and rear parts of 2a are used to control the backward movement of the sliders 4 and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com