Gyrotron and electronic device using same

A technology of vibrating gyroscope and vibrator, which is applied to measurement devices, gyro effect for speed measurement, gyroscope/steering sensing equipment, etc., can solve the problems of low height tendency violation and high height of the vibrating gyroscope on the installation substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

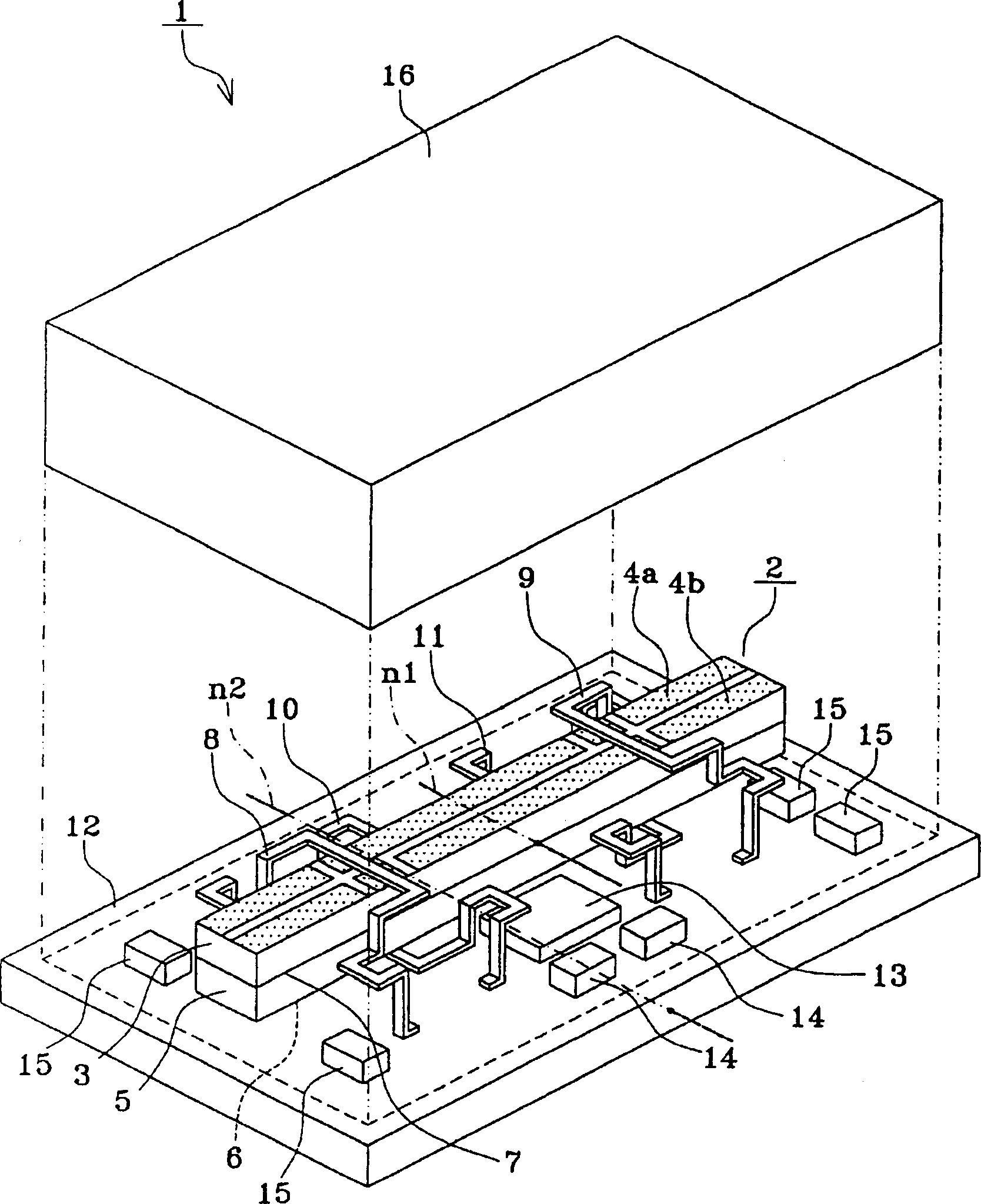

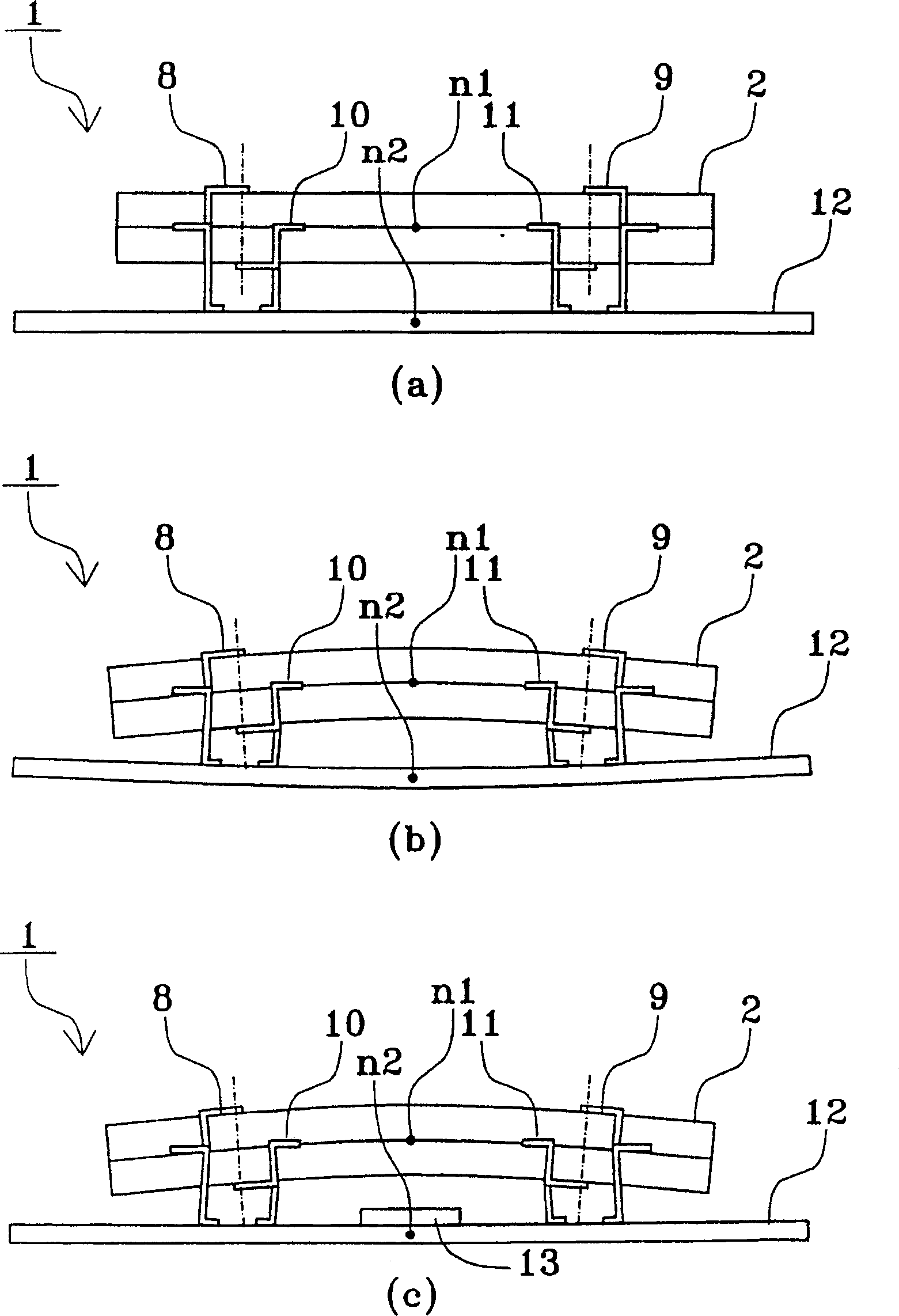

[0020] figure 1 A perspective view showing an embodiment of the vibrating top of the present invention. exist figure 1 Among them, the top 1 has: a vibrator 2; conductive support members 8, 9, 10, 11 made of metal such as plate-shaped Fe-Ni containing gold or phosphor bronze; a mounting substrate 12; the vibrator 2 is excited and flexurally vibrated Components 13 , 14 , 15 for a drive detection circuit that detect an angular velocity applied to the vibrator 2 from a signal output from the vibrator 2 ; and a cover 16 .

[0021] The vibrator 2 is formed by forming the piezoelectric substrate 3 with the electrodes 4a and 4b separated in the width direction on one main surface while being polarized in the thickness direction, and forming the piezoelectric substrate 3 on one main surface while being polarized in the thickness direction. The piezoelectric substrate 5 of the electrode 6 is bonded to each other on the other main surface via the electrode 7 to form a bimorph structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com