Method for controlling power supply to current vertex decelerator

A technology of eddy current retarder and power supply control, which is applied in the direction of control system, electromechanical brake control, electrical components, etc., which can solve the problems of increased energy consumption of automobiles, and achieve the effects of reduced magnetic flux loss, reduced volume, and reduced electrical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

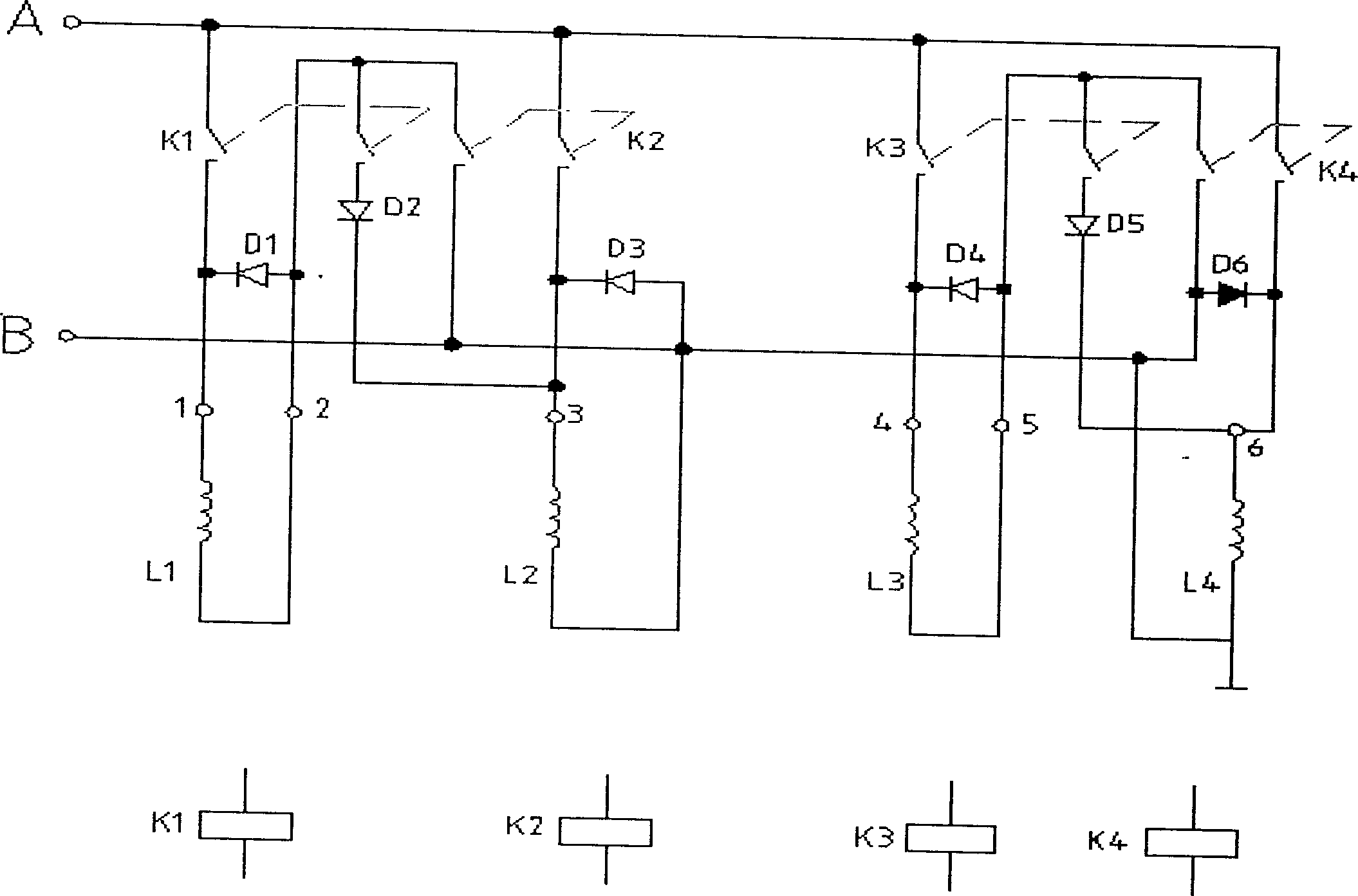

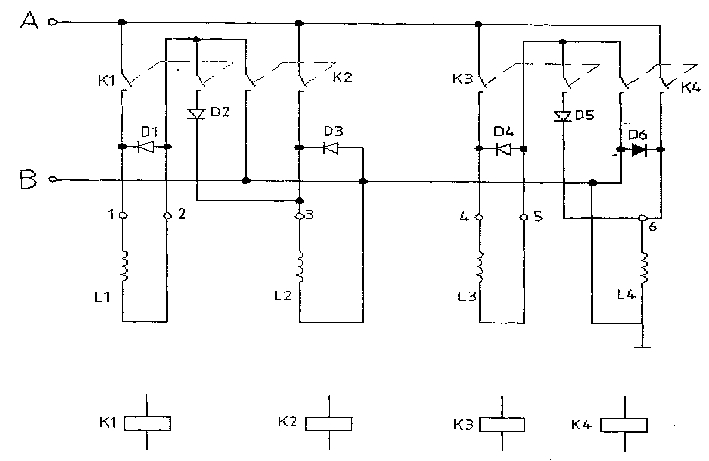

[0007] Example 1: Press figure 1 Shown is a schematic circuit diagram of the switching circuit of an actual embodiment, which has been simplified to a certain extent according to the actual situation. It is connected to a lowest power range and adopts a control mode of two sets of excitation coils in series. There are retarder coils L1, L2, L3 and L4, switching diodes D2 and D5, freewheeling absorption diodes D1, D3, D4 and D6, double contact relays K1, K2, K3 and K4, through the control of double contact relay K1 , K2, K3 and K4 are opened and closed, and the retarder coils L1, L2, L3 and L4 are combined to form different series and parallel connections. When K1 or K3 pulls in, L1 and L2 are connected in series or L3 and L4 are connected in series. When K1 and K3 are pulled in at the same time, L1 and L2 are connected in series, and after L3 and L4 are connected in series, the two are connected in parallel. When K1, K2, and K3 are pulled in at the same time, L1 and L2 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com