Chain tensioner

A technology of applying device and tensioning force, applied in the direction of transmission, belt/chain/gear, machine/engine, etc., can solve problems such as partial wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Preferred embodiments of the chain tension applying device according to the present invention will now be described with reference to the accompanying drawings.

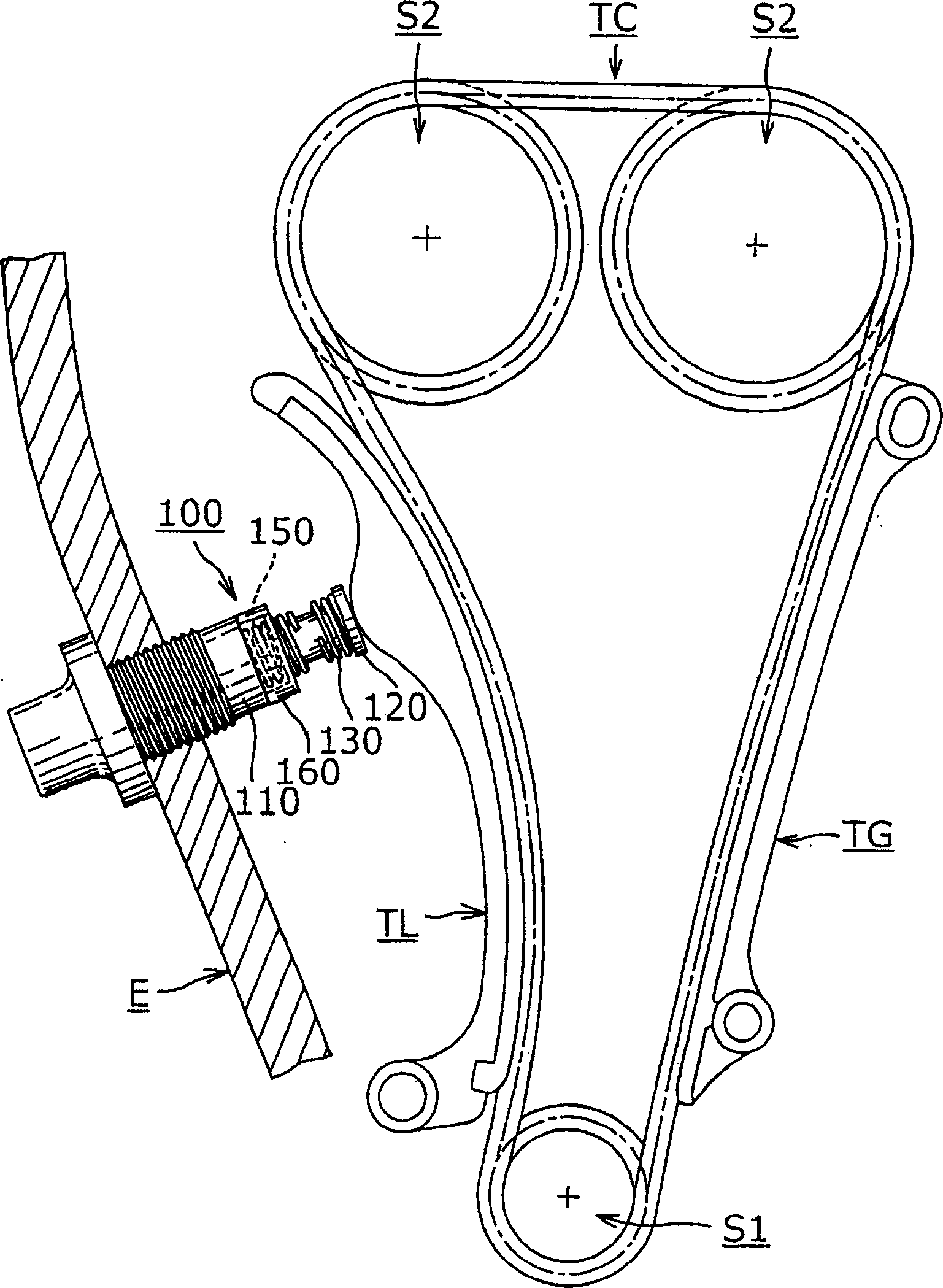

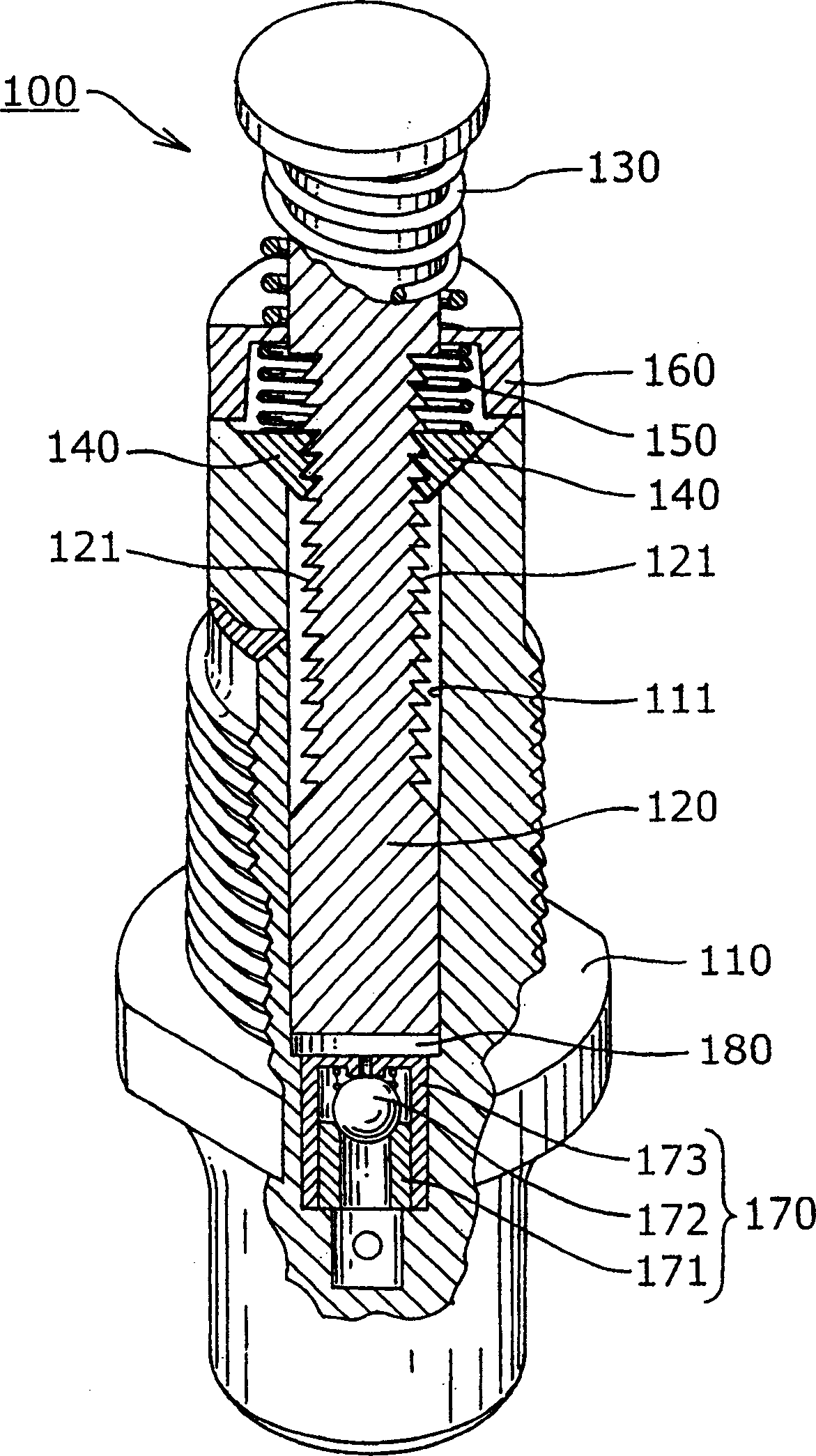

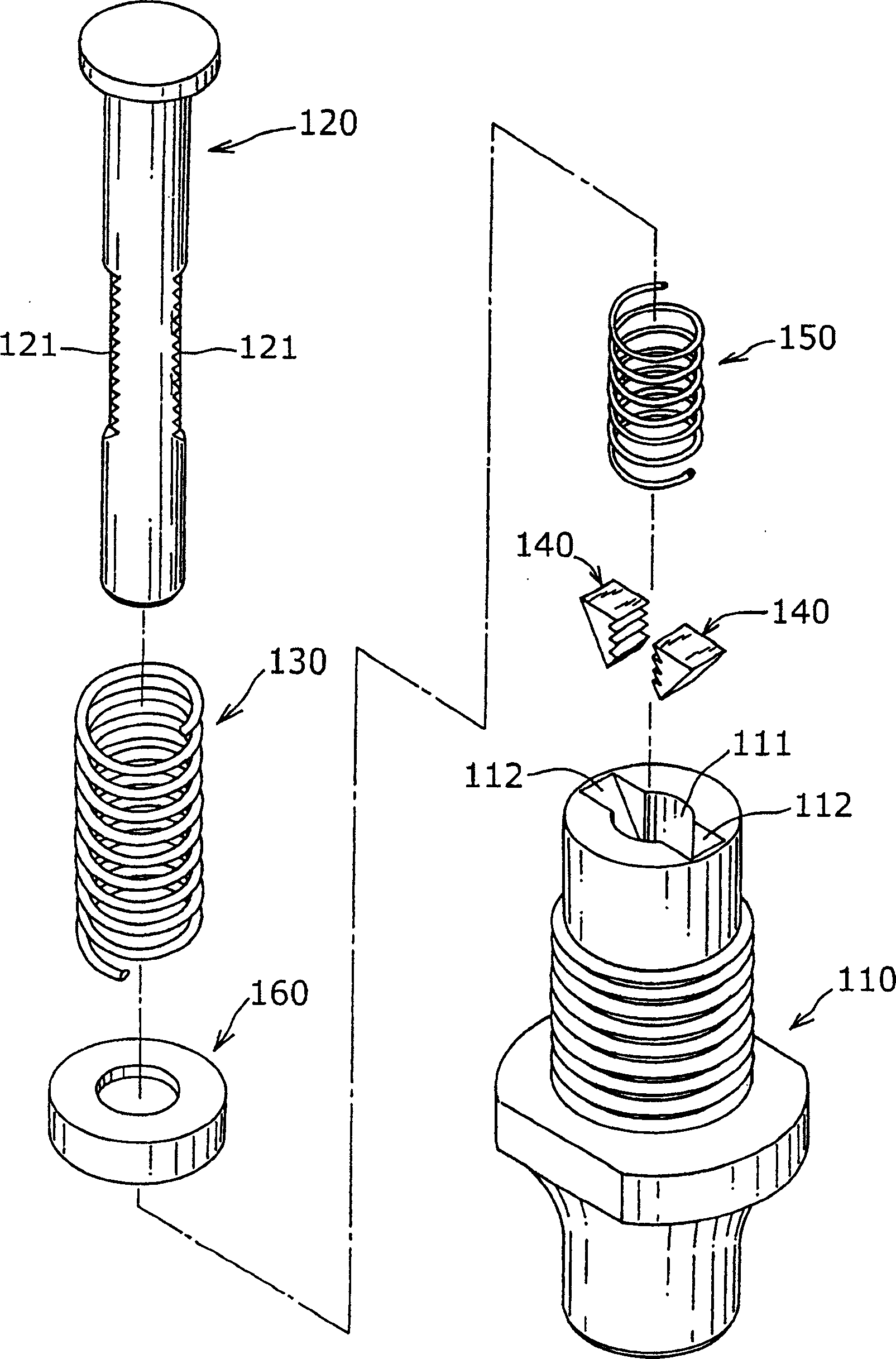

[0036] First, the chain tension applying device 100 of the first example of the present invention will be described. figure 1 is a structural diagram of a chain tension applying device according to a first example of the present invention, figure 2 yes figure 1 A partial sectional schematic diagram of the chain tensioning force application device shown, image 3 yes figure 1 An exploded view of the chain tensioning device shown and its assembled view, Figure 4(a)-4(c) yes figure 1 The working explanatory diagram of the shown chain tension applying device, specifically, Fig. 4(a) is a view showing the state just before exerting the check function, and Fig. 4(b) is a view showing the moment when the check function is released. The view of the state, and Figure 4 (c) is a view showing the state when the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com