Steam releasing device for pressure cooker

A technology of a discharge device and a pressure cooker, applied in the field of pressure cookers, can solve the problems of being difficult to keep clean, unable to remove condensed water, etc., and achieve the effect of clean use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

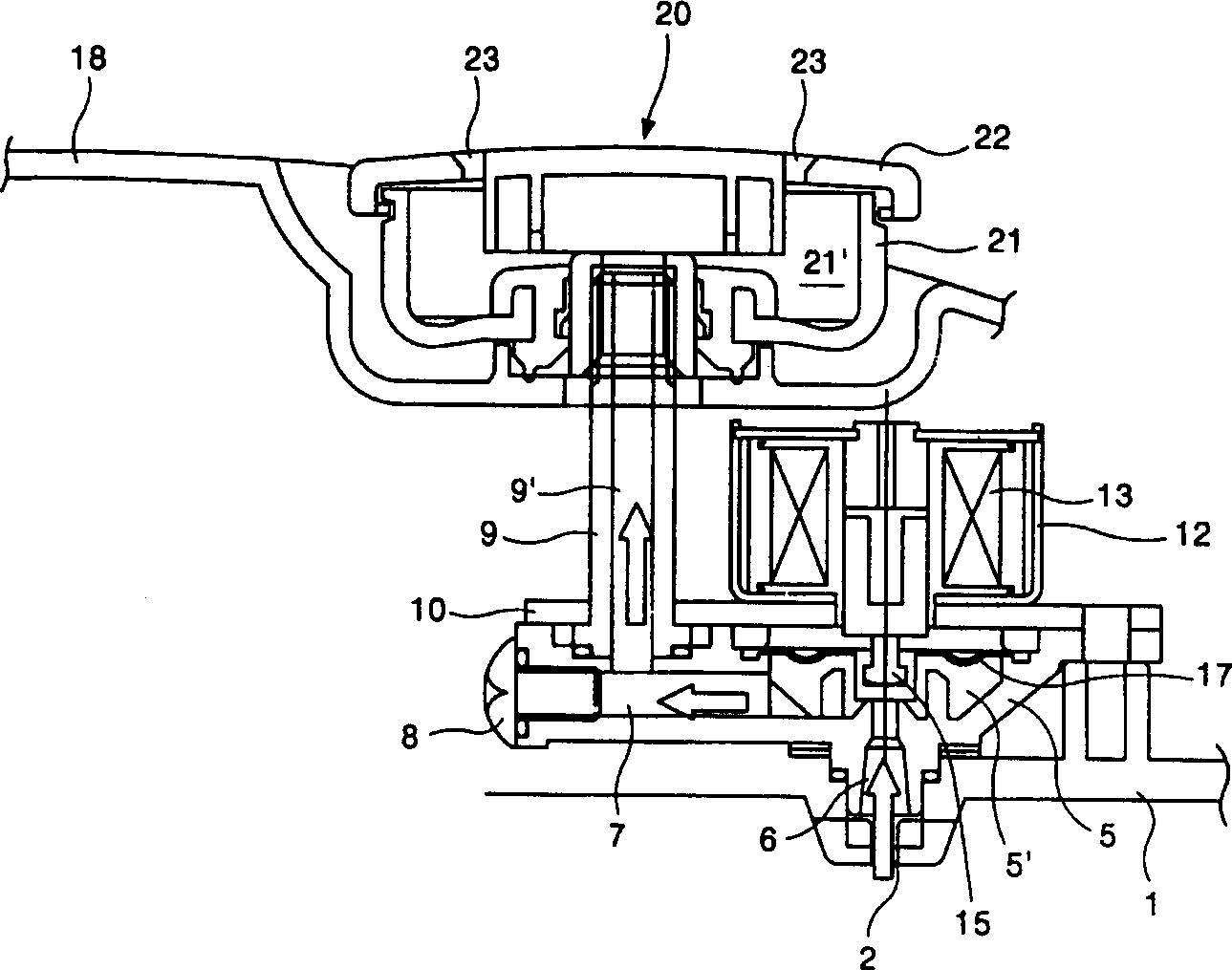

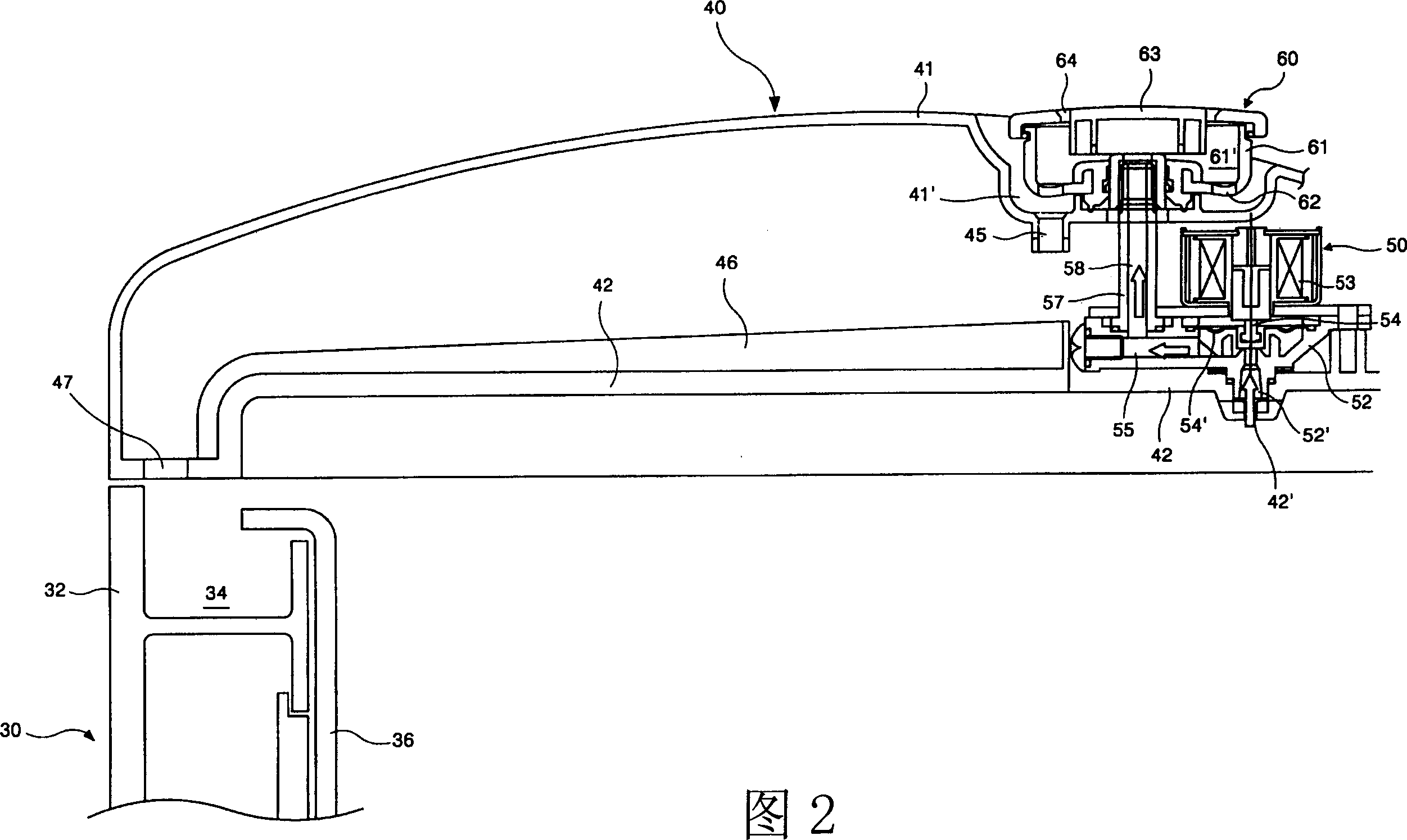

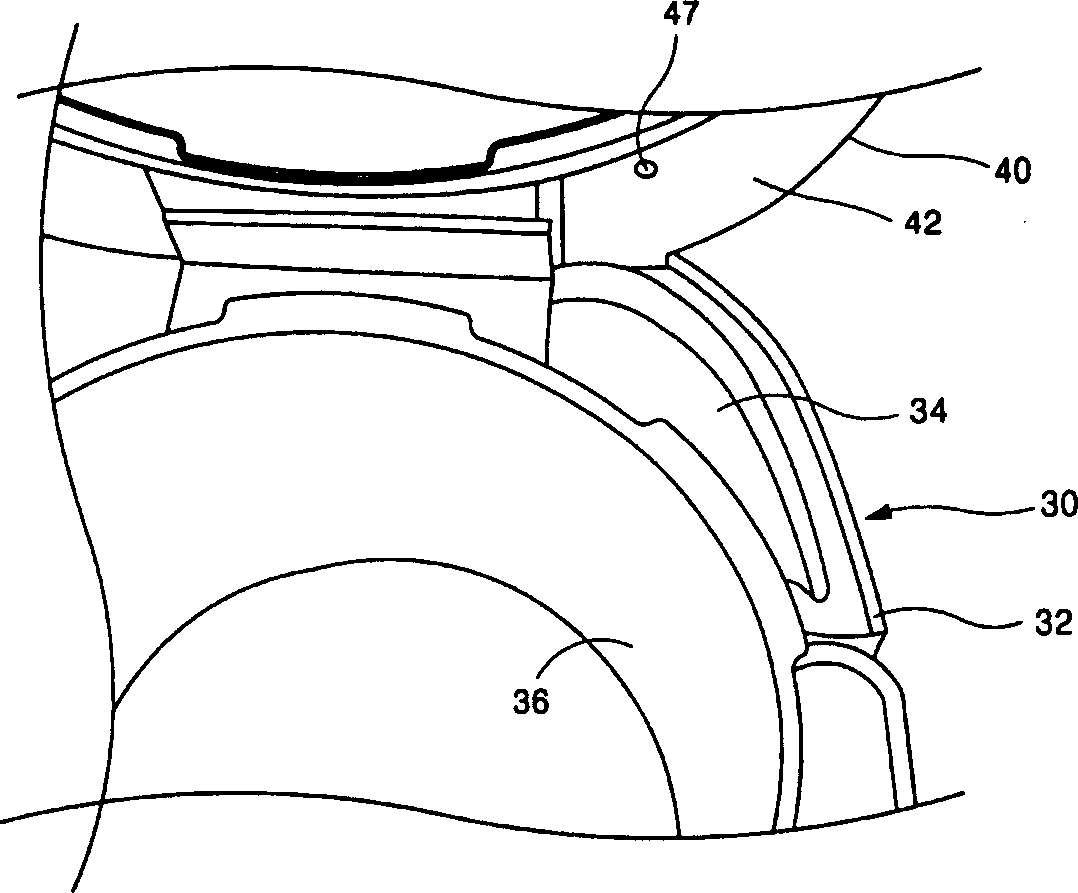

[0026] Figure 2 and image 3 Shown, pressure cooker is made of body (30) and pot cover (40). The body (30) includes a cooking pot (36) that provides space for cooking. The pot cover (40) is contained in the upper end of the body (30), and communicates with the outside selectively to the inside of the cooking pot (36).

[0027] Such as image 3 Shown, in body (30) inside, be provided with a space that can lay rice cooker (36). Loam cake (32) body (30) upper end. On the top side of the upper cover (32), a condensed water storage part (34) is provided. The condensed water storage part (34) becomes the collection and storage part of the condensed water mixed in the steam discharged from the cooking pot (36) during the cooking process or after the cooking is finished, and is arranged in the space above the upper cover (32) . Moreover, the upper part of the condensed water storage part can be opened, and the user can see it by lifting the pot cover (40).

[0028] The pot cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com