Reverse-washing type fine water quality purifier

A backwash type and purifier technology, applied in the field of water treatment, can solve problems such as difficult to meet requirements, large space occupation, complex structure, etc., and achieve high practical value, prolong service life, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

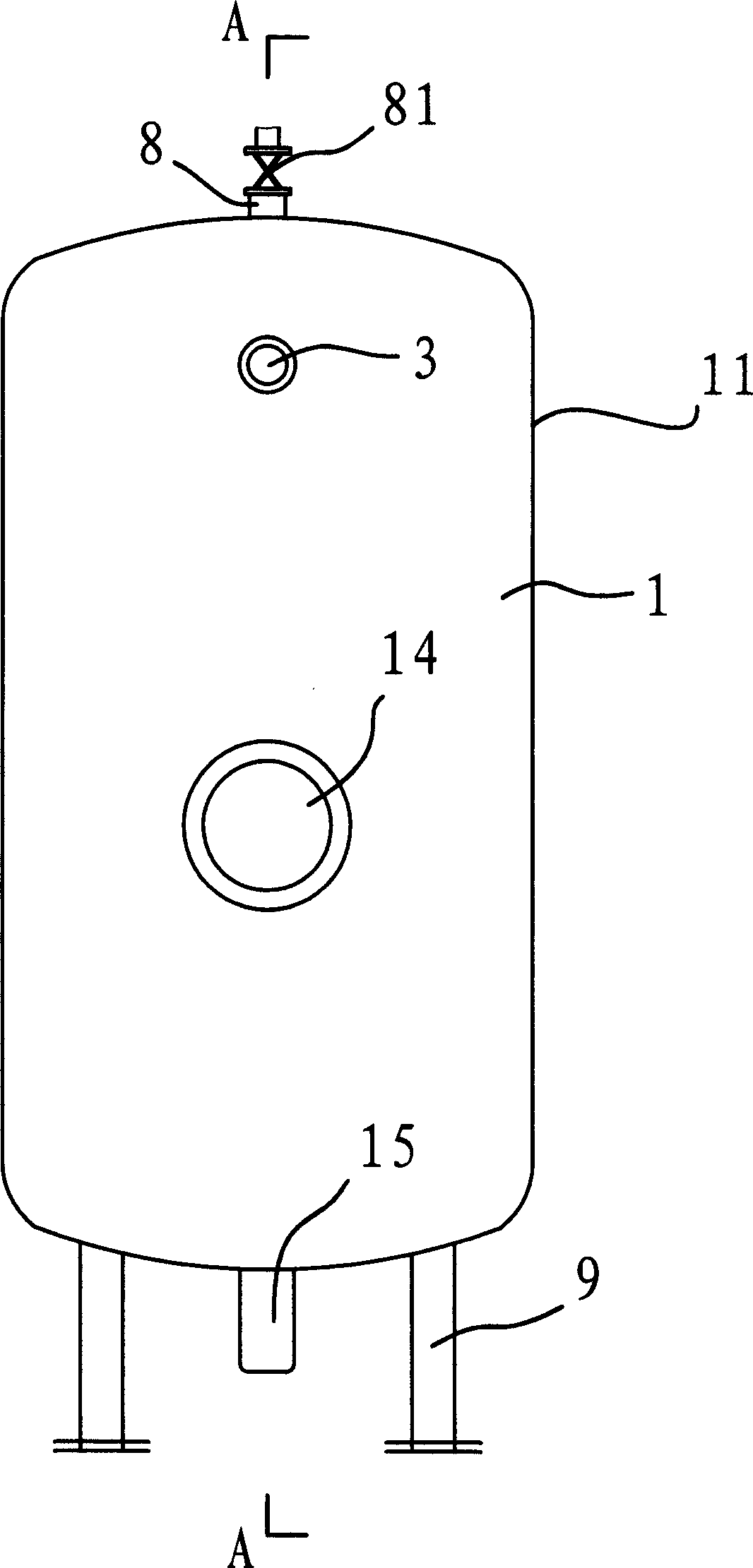

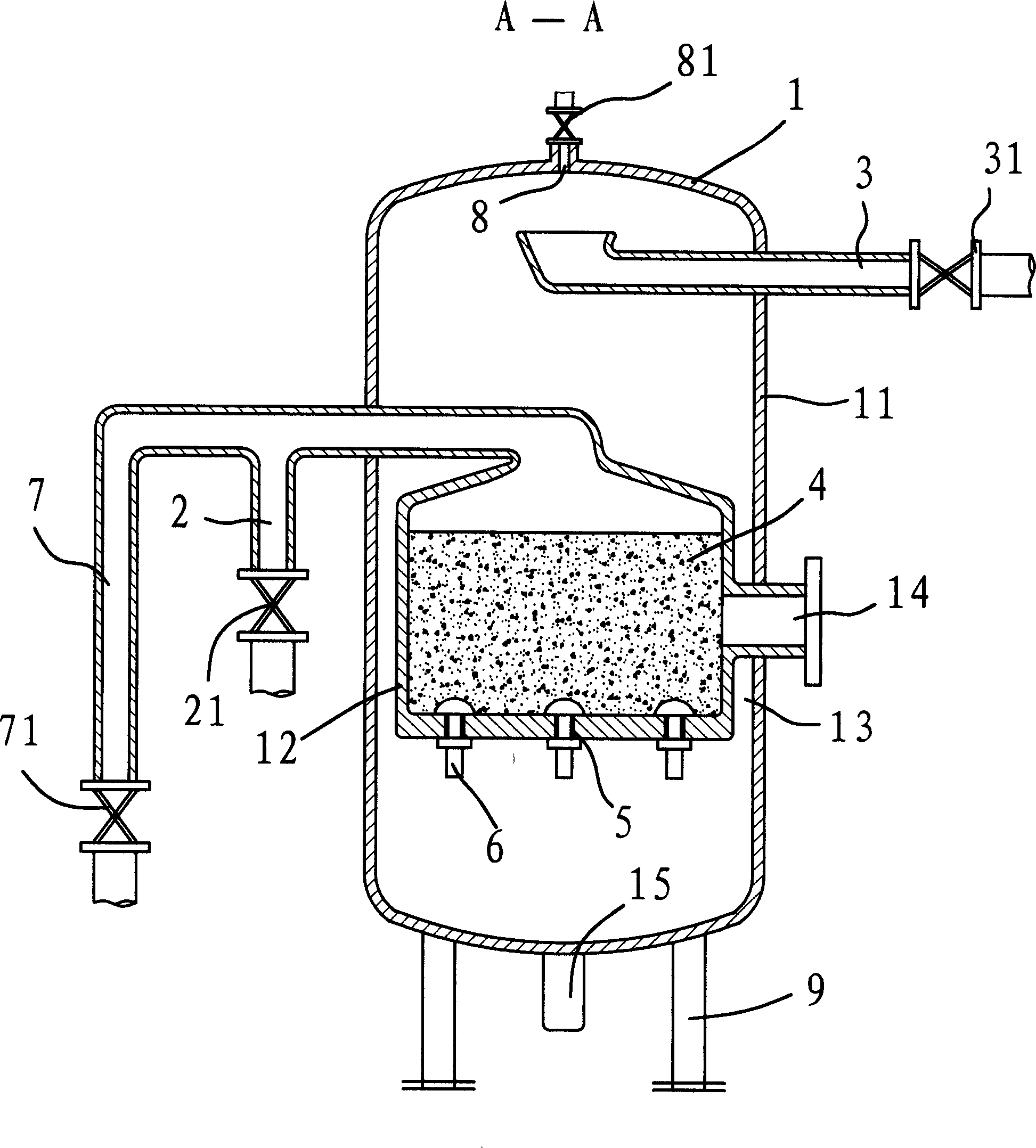

[0023] Such as figure 1 with figure 2 As shown, the backwash type deep water purifier includes a housing 1, a water inlet pipe 2, an outlet pipe 3, a filter material 4, a backwash sewage pipe 7 and other parts. The casing 1 is composed of an outer casing 11 and an inner casing 12 . In this embodiment, the outer casing 11 is cylindrical. The shape of the outer shell 11 can also be square, triangular and other shapes. The inner casing 12 is placed in the outer casing 11 and its shape is similar to that of the outer casing 11 .

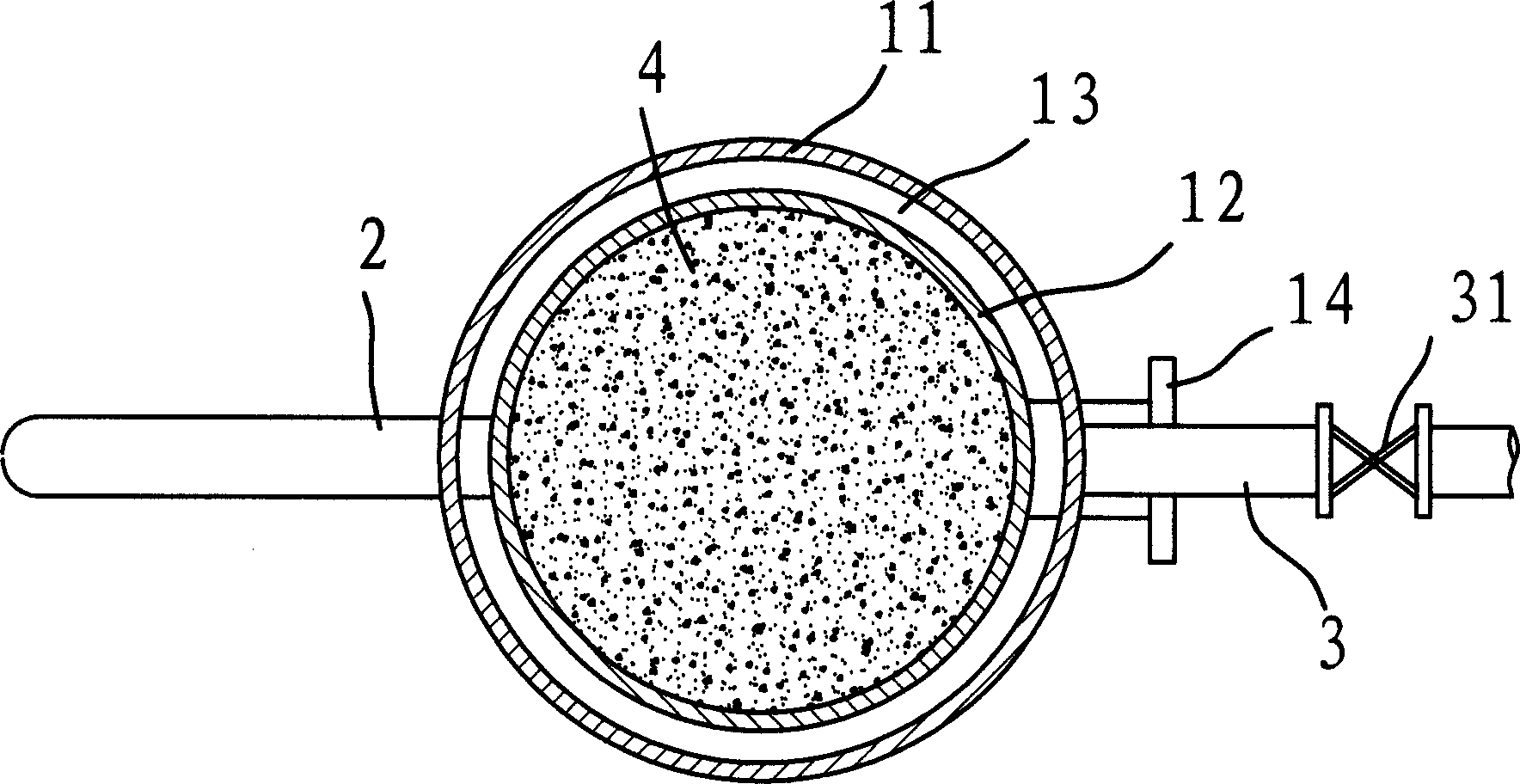

[0024] Such as figure 2 with image 3 As shown, there is a drainage gap 13 between the inner shell 12 and the outer shell 11 for water to flow through. In this embodiment, the drainage gap 13 is naturally formed by the size difference between the inner casing 12 and the outer casing 11 . The drainage gap 13 can also be several drainage holes provided between the inner casing 12 and the outer casing 11, which can also achieve the same purpose.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com