Cross flow fan

A technology of cross-flow fans and fans, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., to prevent mutual influence, improve performance, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

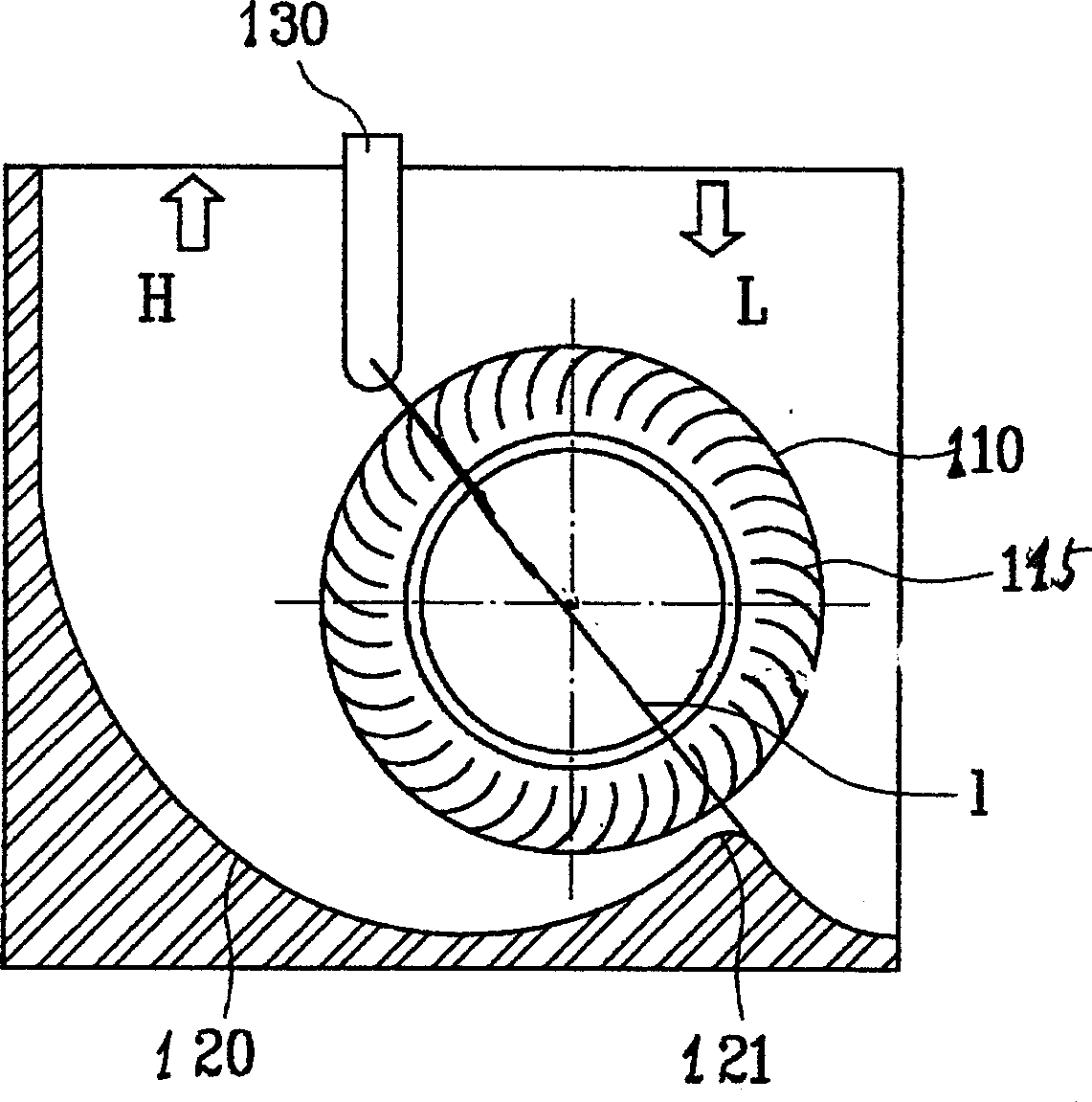

[0031] like Figure 2a and Figure 2b As shown, the cross-flow fan of the present invention includes: an impeller component 110 , a motor (not shown in the figure), a rear guide surface 120 , a boundary plate 113 , a stabilizer 130 and an exhaust guide plate 140 .

[0032] The impeller part 110 includes: 3 unit fans 111 connected in series by annular boundary plates, and each unit fan 111 includes several blades 115 curved along the rotation direction and arranged at equal intervals; the rotating shaft of the impeller part 110 is connected with the motor The crankshaft 50 is connected.

[0033] The rear guide surface 120 is arranged at the rear part of the impeller component casing to form a discharge flow path for sucked air. One side of the rear guide surface 120 is provided with a gap part 121, and the gap part 121 is formed along the axial direction; the stable The device 130 is arranged on one side of the impeller housing along the axial direction, and together with the...

Embodiment approach 2

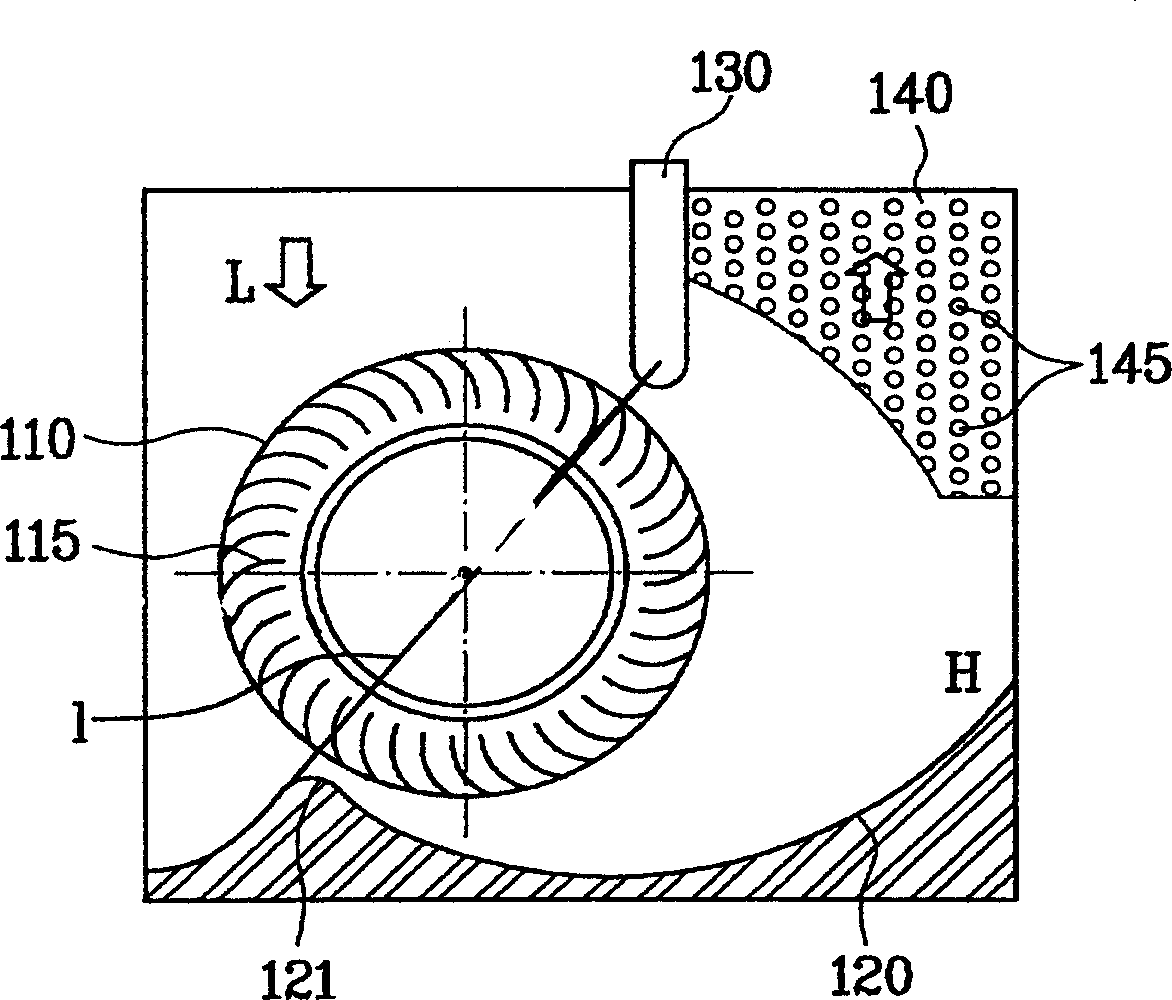

[0038] like image 3 As shown, the cross-flow fan of the present invention includes: an impeller component 110 , a motor (not shown in the figure), a rear guide surface 120 , a boundary plate 113 , a stabilizer 130 and an exhaust guide plate 140 .

[0039] The impeller part 110 includes: 3 unit fans 111 connected in series by annular boundary plates, and each unit fan 111 includes several blades 115 curved along the rotation direction and arranged at equal intervals; the rotating shaft of the impeller part 110 is connected with the motor The crankshaft 50 is connected.

[0040] The rear guide surface 120 is arranged at the rear part of the impeller component casing to form a discharge flow path for sucked air. One side of the rear guide surface 120 is provided with a gap part 121, and the gap part 121 is formed along the axial direction; the stable The device 130 is arranged on one side of the impeller housing along the axial direction, and together with the gap part 121 form...

Embodiment approach 3

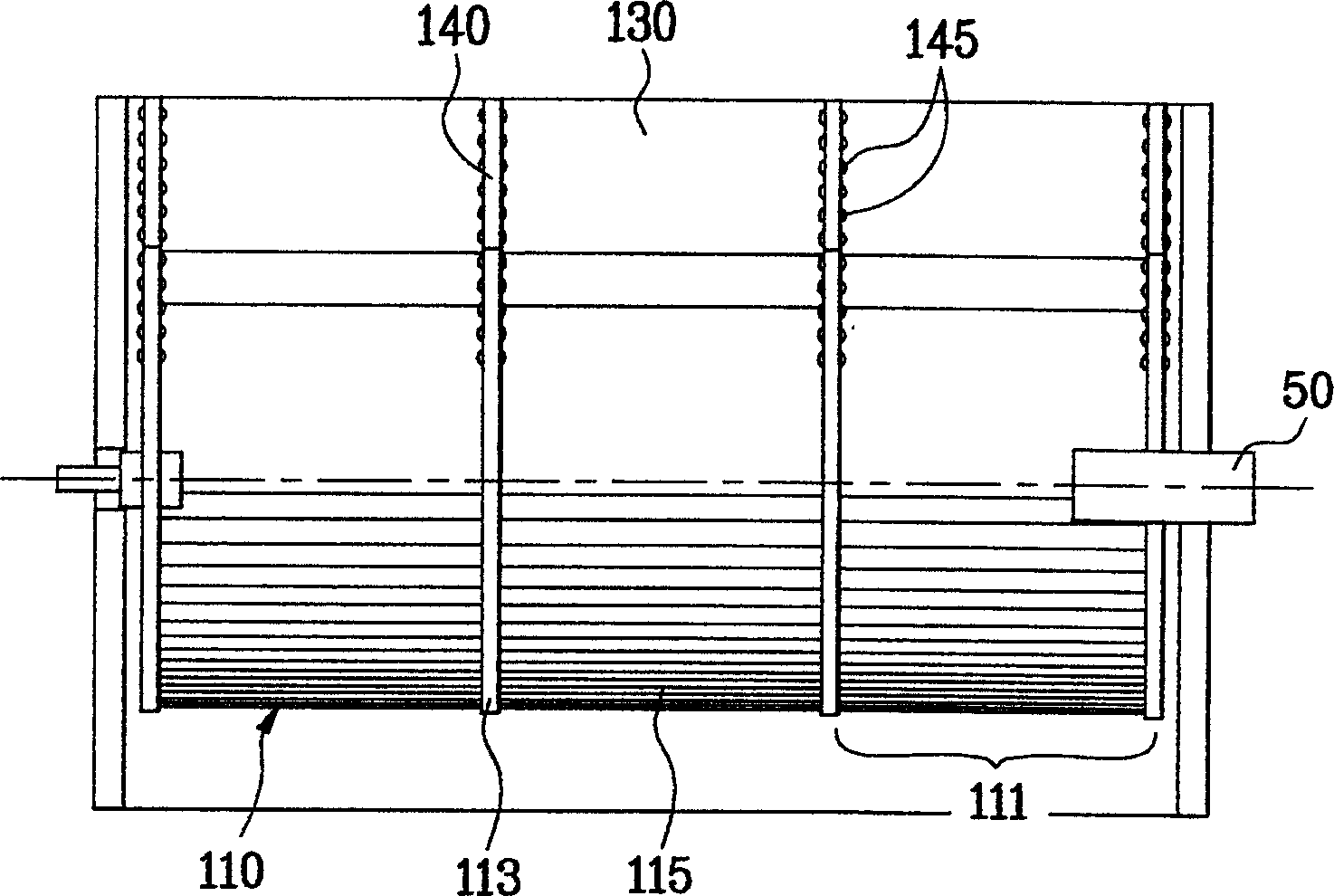

[0045] like Figure 4 As shown, the cross-flow fan of the present invention includes: an impeller component 110 , a motor (not shown in the figure), a rear guide surface 120 , a boundary plate 113 , a stabilizer 130 and an exhaust guide plate 140 .

[0046] The impeller part 110 includes: 3 unit fans 111 connected in series by annular boundary plates, and each unit fan 111 includes several blades 115 curved along the rotation direction and arranged at equal intervals; the rotating shaft of the impeller part 110 is connected with the motor The crankshaft 50 is connected.

[0047] The rear guide surface 120 is arranged at the rear part of the impeller component casing to form a discharge flow path for sucked air. One side of the rear guide surface 120 is provided with a gap part 121, and the gap part 121 is formed along the axial direction; the stable The device 130 is arranged on one side of the impeller housing along the axial direction, and together with the gap part 121 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com