Case for packaging optical device and making method thereof

A technology of optical devices and manufacturing methods, applied in laser parts, lasers, semiconductor lasers, etc., can solve the problems of affecting light transmittance, long production cycle, high cost, reduce assembly workload, improve cost performance, and shorten production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

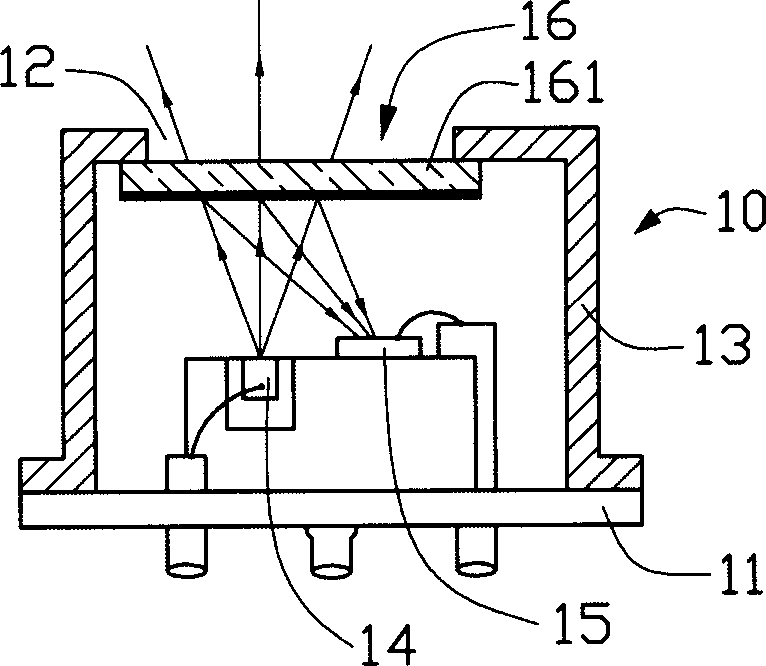

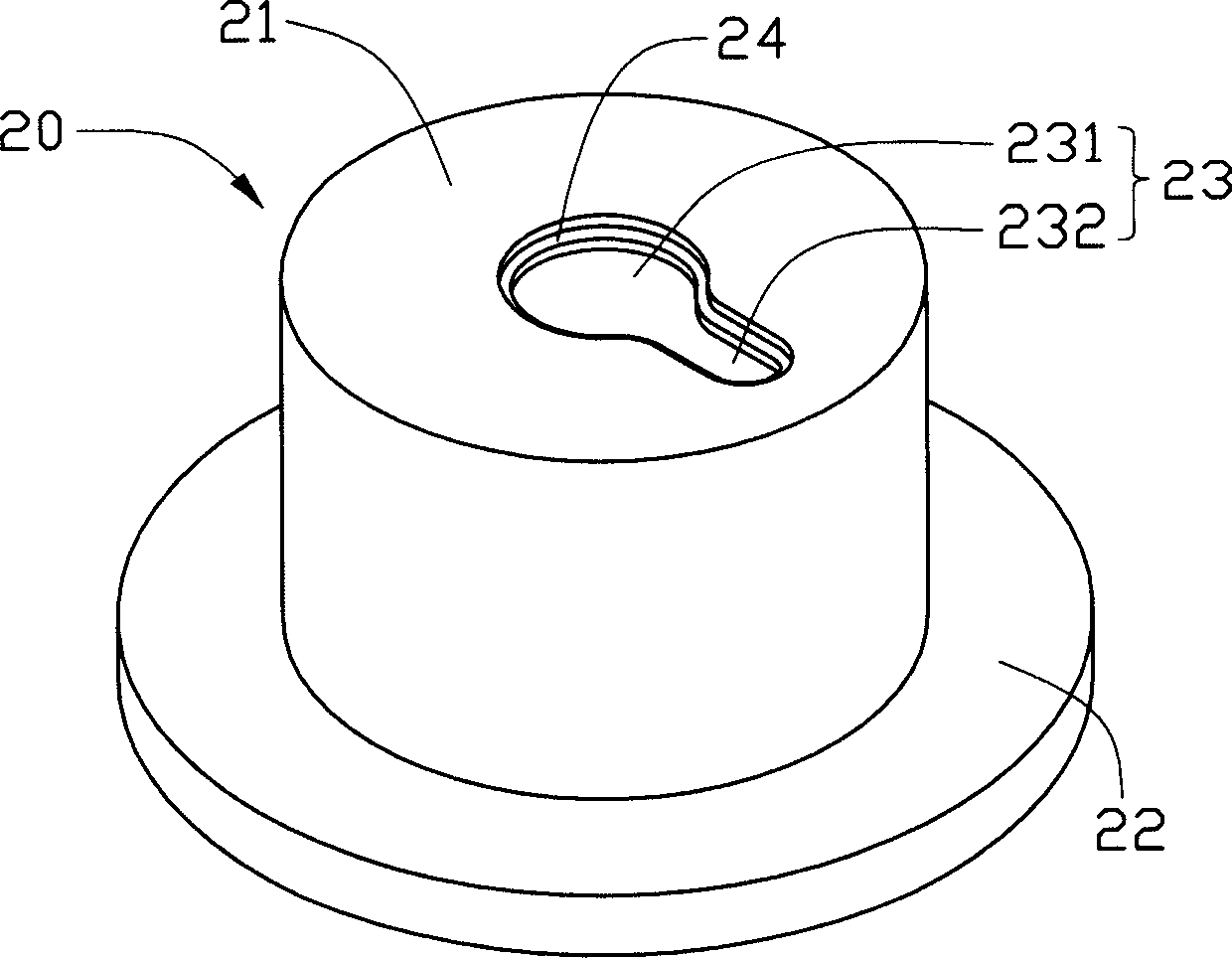

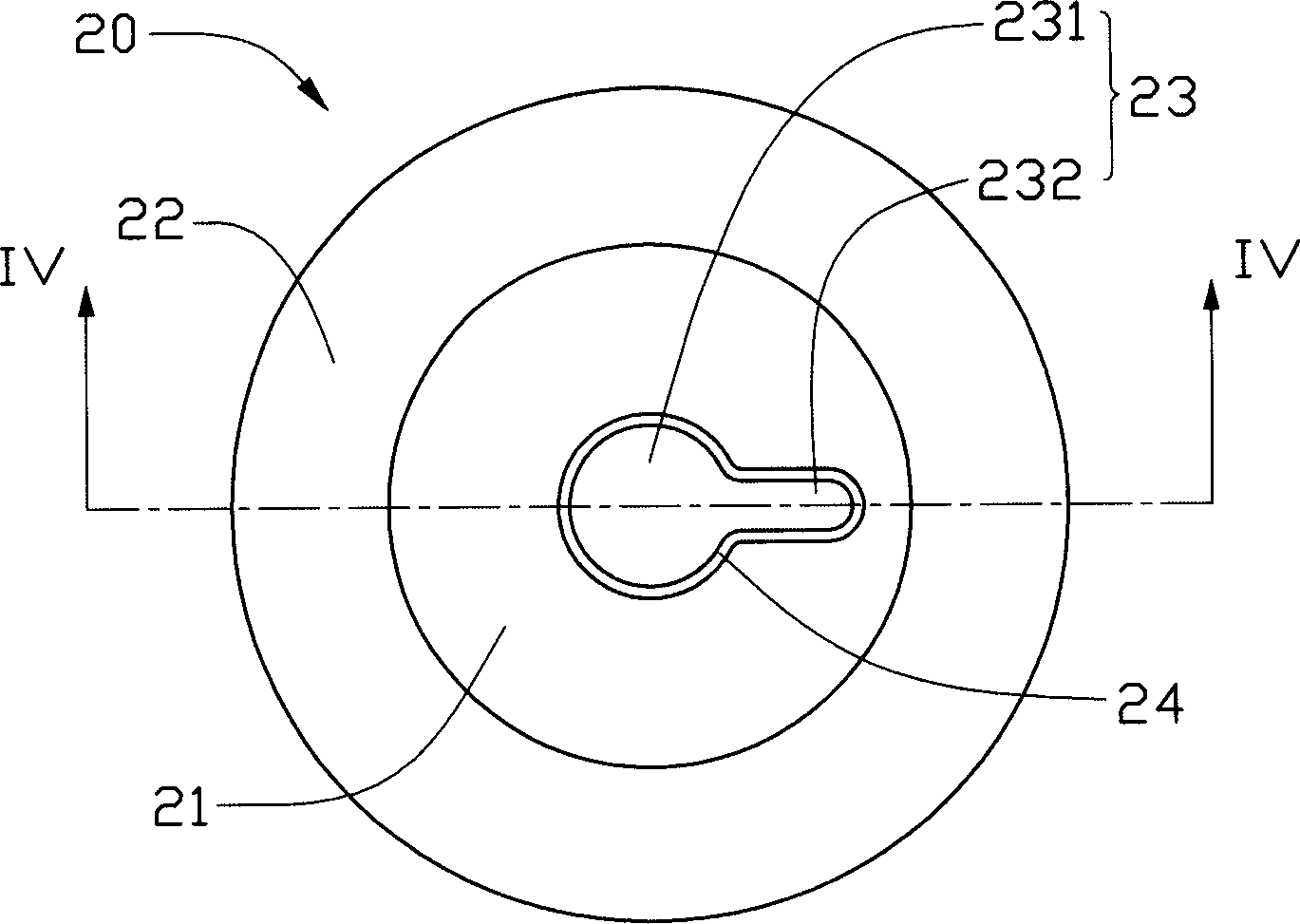

[0017] The optical device packaging cover and its manufacturing method of the present invention include the steps of providing a casing and an optical lens (described in detail later), please refer to figure 2 and Figure 6 As shown, the optical package 40 includes a housing 20 and an optical lens 31 . The casing 20 has a flat top 21 and an annular bottom plate 22 . The casing 20 is integrally formed and roughly shaped like a pot. Wherein the flat top 21 has a through optical lens mounting portion 23 , and the optical lens mounting portion 23 includes a light-transmitting opening 231 and a channel opening 232 . In addition, the ring-shaped bottom plate 22 is a brim-shaped ring-shaped bottom plate extending outward from the bottom end of the housing 20 along the edge of the housing, so that the encapsulating cover is compatible with the base (not shown) on which the optical device is placed when packaging the optical device (not shown). ) can be closely matched. The housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com