New enginering structure and material deformation measuring technology

A technology for engineering structure and material deformation, applied in the direction of analyzing materials, optical testing flaws/defects, instruments, etc., can solve the problem of inapplicability of large deformation measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The carrier of the deformation information is the feature point, which must first be extracted or prepared on the surface of the measured object.

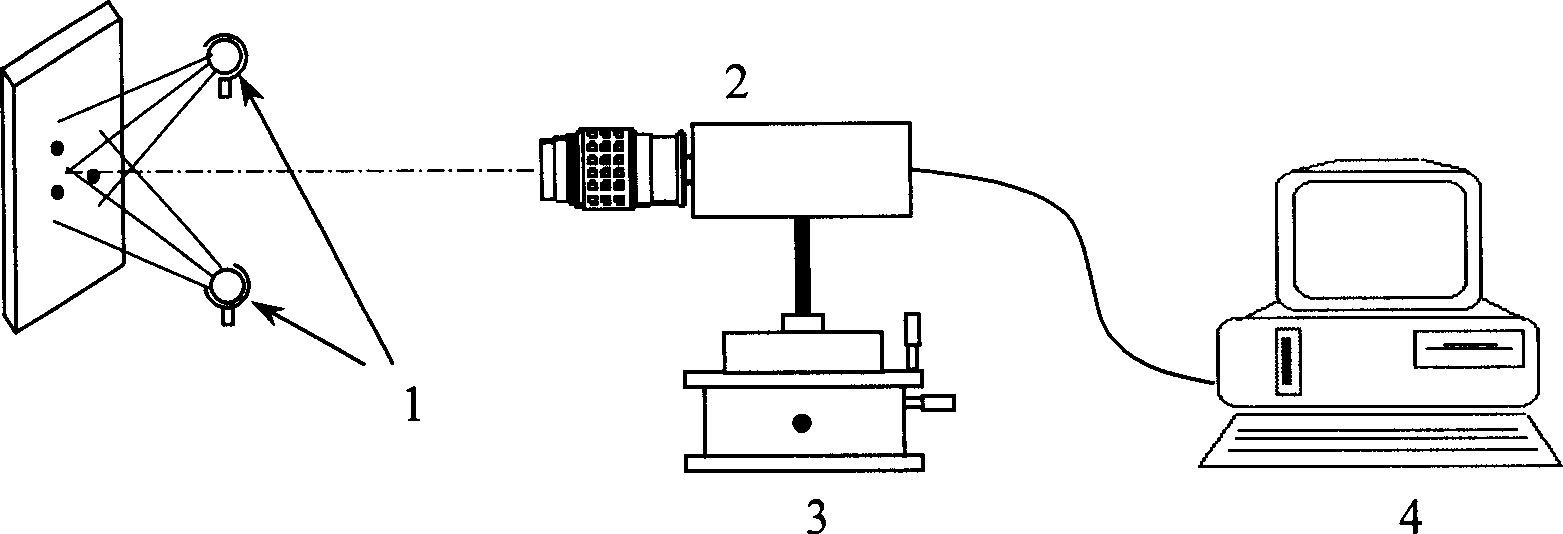

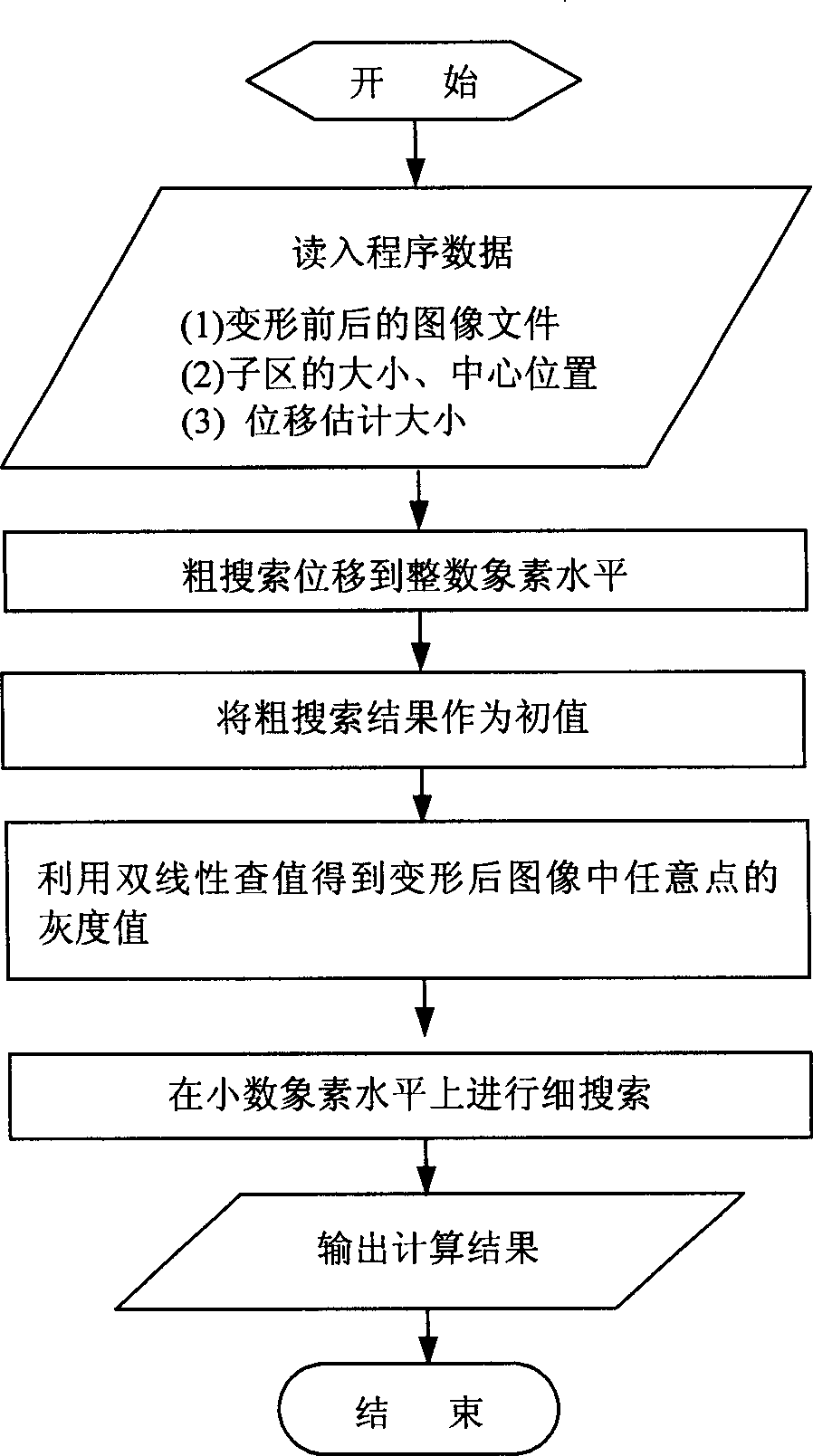

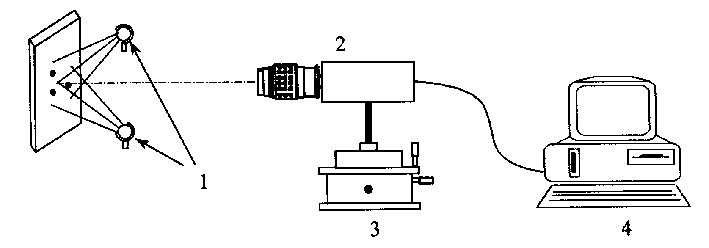

[0009] The following is attached figure 1 Describe the measurement process of this technique. The light source (1) and the CCD camera (2) are adjusted to obtain clear video signals of feature points, and the three-dimensional mobile platform (3) is adjusted so that the normal direction of the measured object is perpendicular to the axis of the CCD camera (2). Before the object is deformed, the feature point images on the surface of the object are taken by the CCD camera, and the taken images are transmitted to the control computer (4), and converted into digital images by the analog-to-digital conversion of the image acquisition card in the computer, and stored in the computer to form data files. During the detection process, all instruments and equipment cannot be moved. With the deformation of the object, the image acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com