Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, wheels, etc., and can solve the problems of increasing the wear speed and abnormal wear of the end part of the tire surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

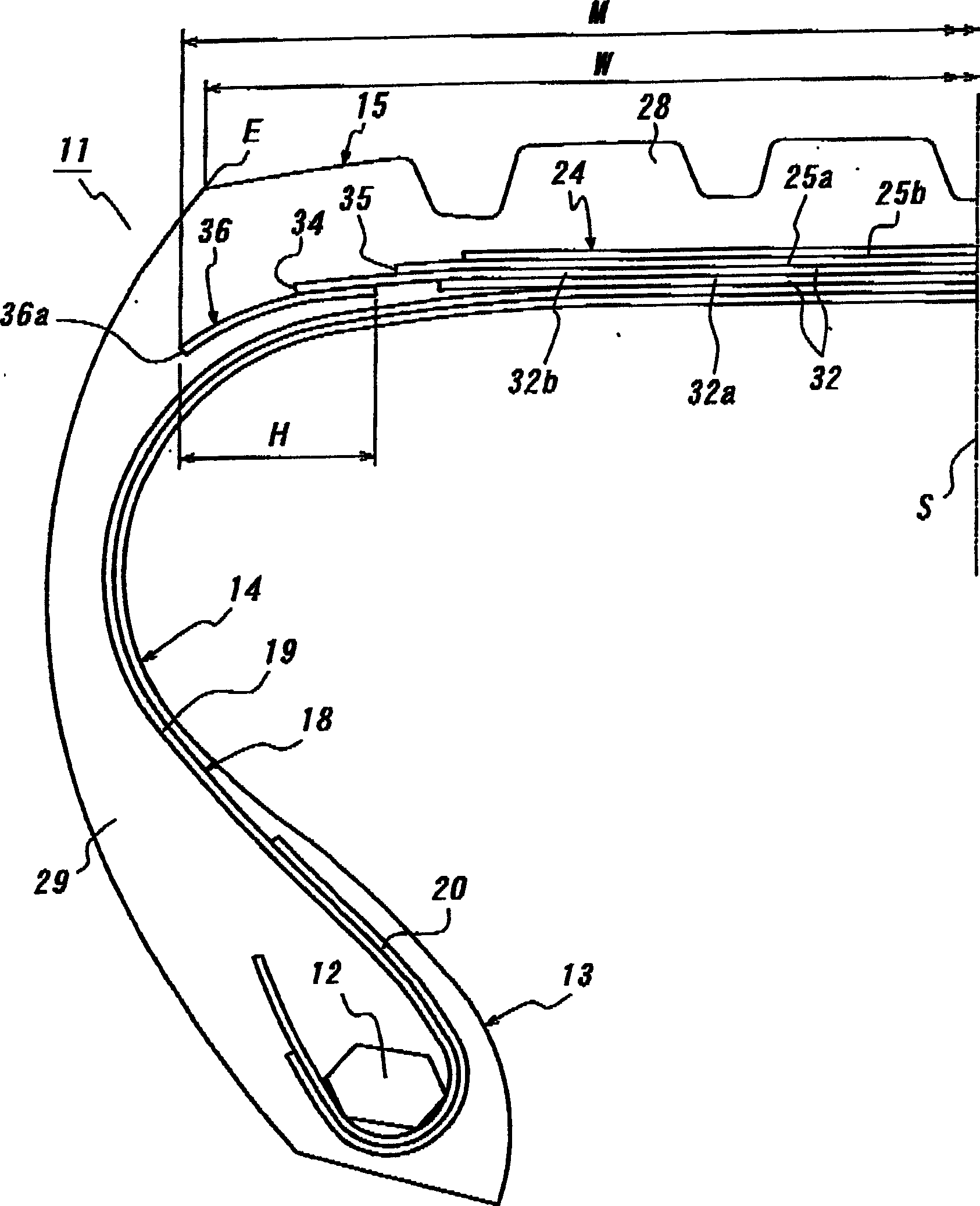

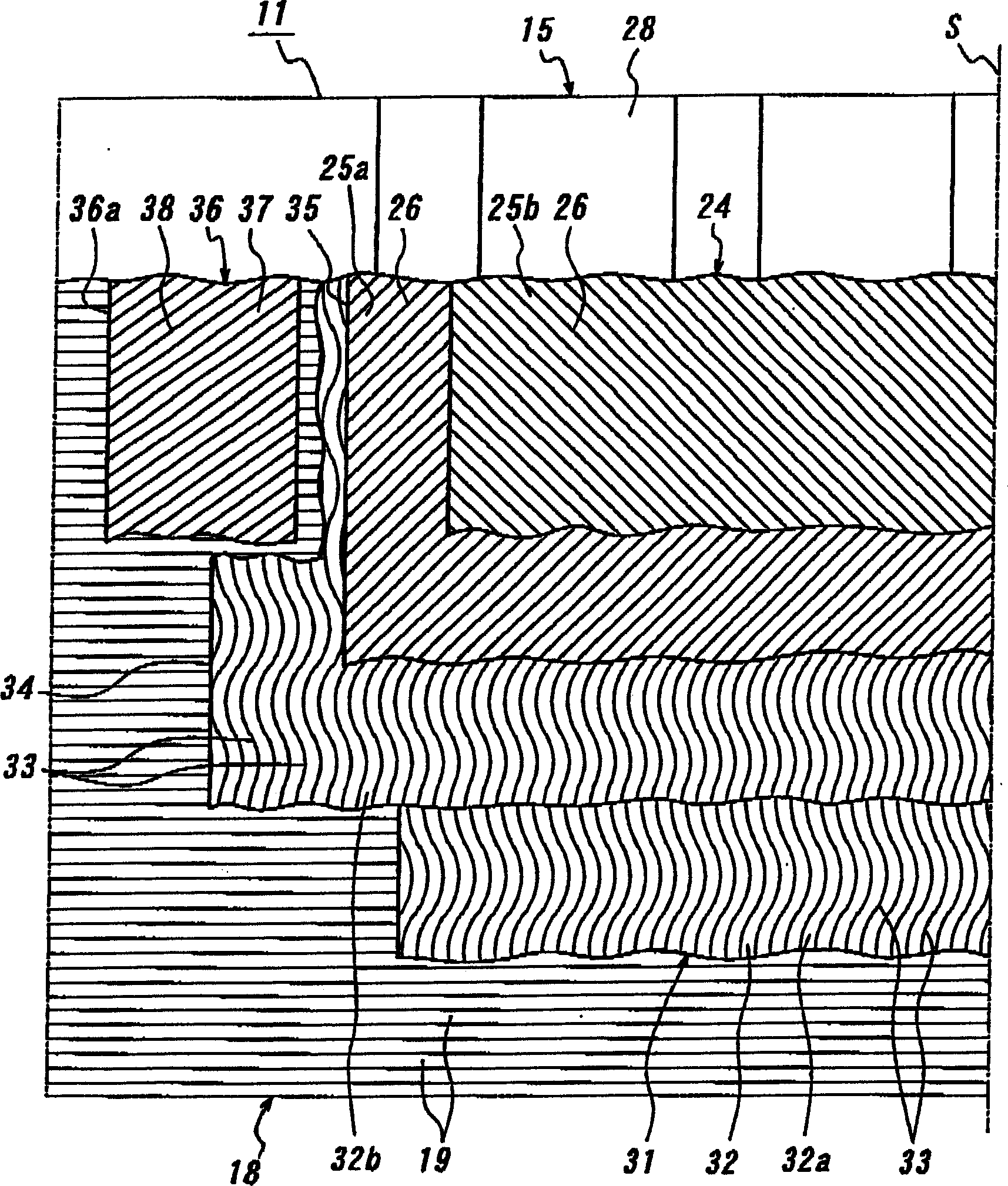

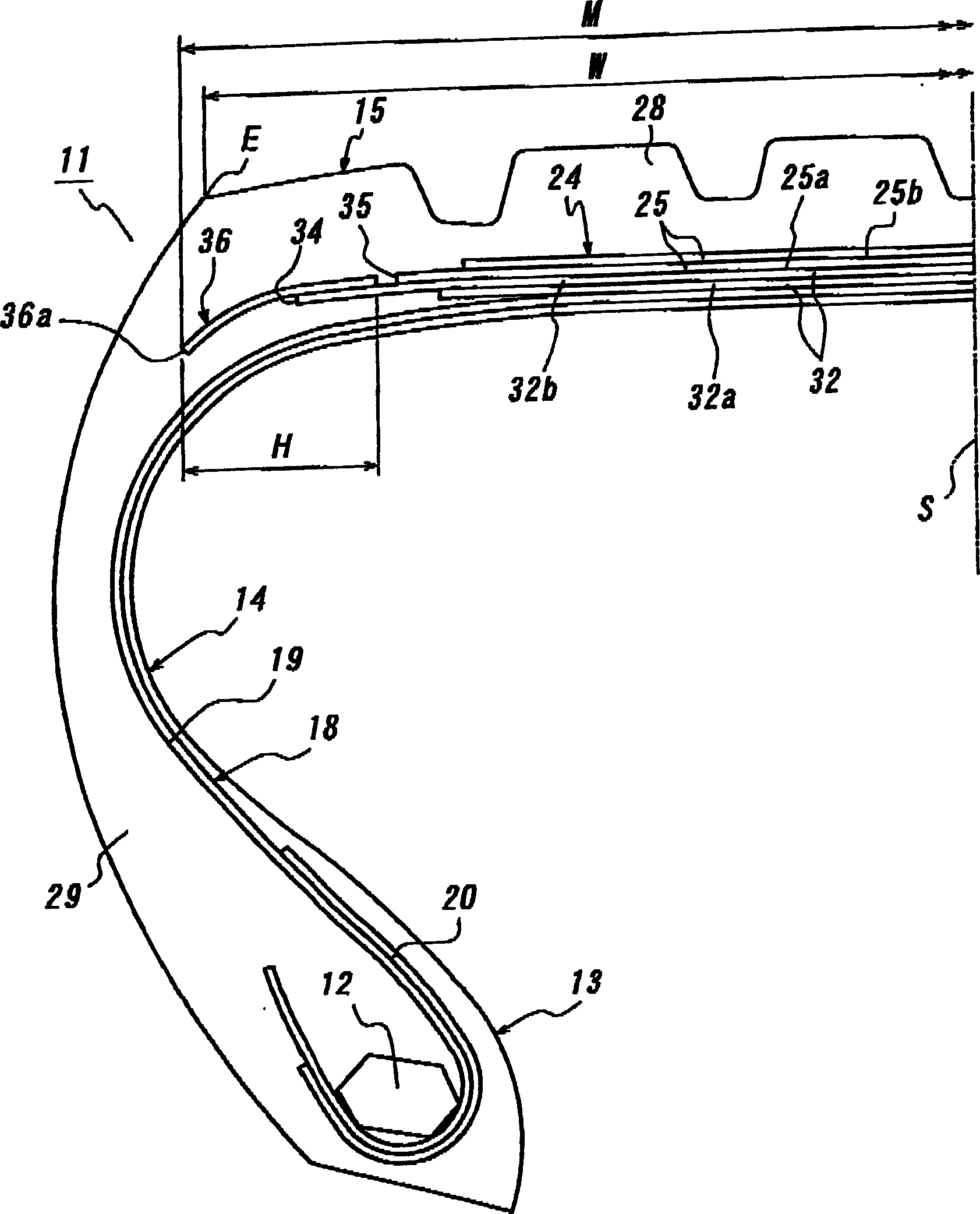

[0055] In order to verify the effect of the present invention, a test was carried out on 31 tires with a size of 435 / 45R22.5 and an axial distance W from the equatorial plane S to the tread end E of 185 mm. Among these tires, a conventional tire has Figure 4 The belt construction shown, except that there is no separate auxiliary belt ply; a control tire has the same belt construction as the conventional tire except that one of the belt plies is the widest. On the other hand, the tires in Examples 1 to 29 had Figure 1-9 Belt construction for the indicated belt layers, belts for the reinforcement layer of dimensions indicated in Table 1, and separate auxiliary belt layers.

[0056] Each test tire was then fitted to a 14.00 x 22.5 rim, internally inflated to a pressure of 900 kPa, and mounted to the drive wheels of a large bus with a 2-D wheel system. Afterwards, the tire ran 10,000km on the expressway at a speed of 80km / h under the condition of a load of 49.0kN. After running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com