Drilling bit structure for enlarging hole

A technology of drill bit and drill bit sleeve, which is applied in the direction of drill bit, earth-moving drilling, drilling equipment, etc., can solve the problems of not being able to be pulled out, hindering the reverse rotation of the extended drill bit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are shown in the accompanying drawings.

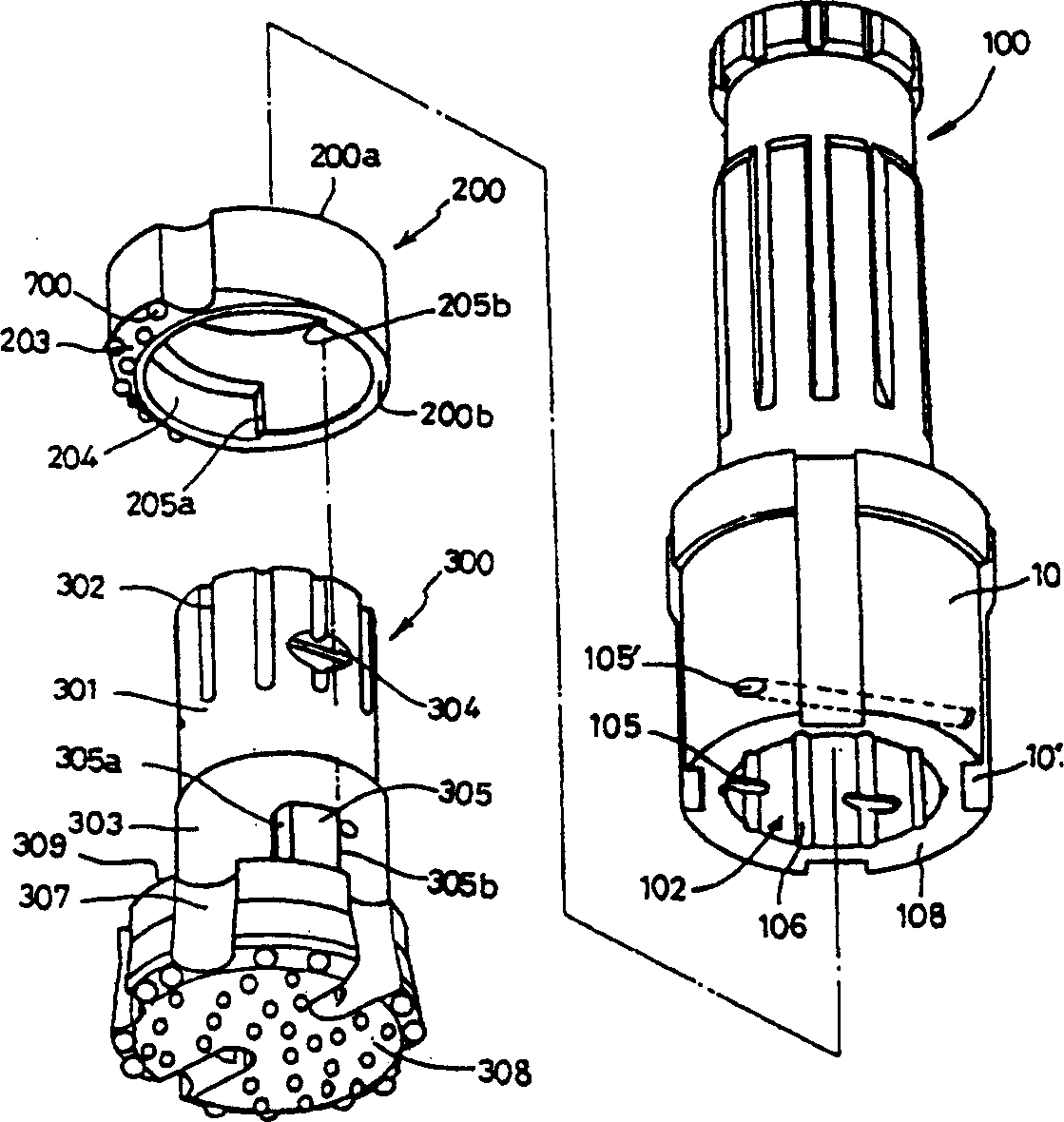

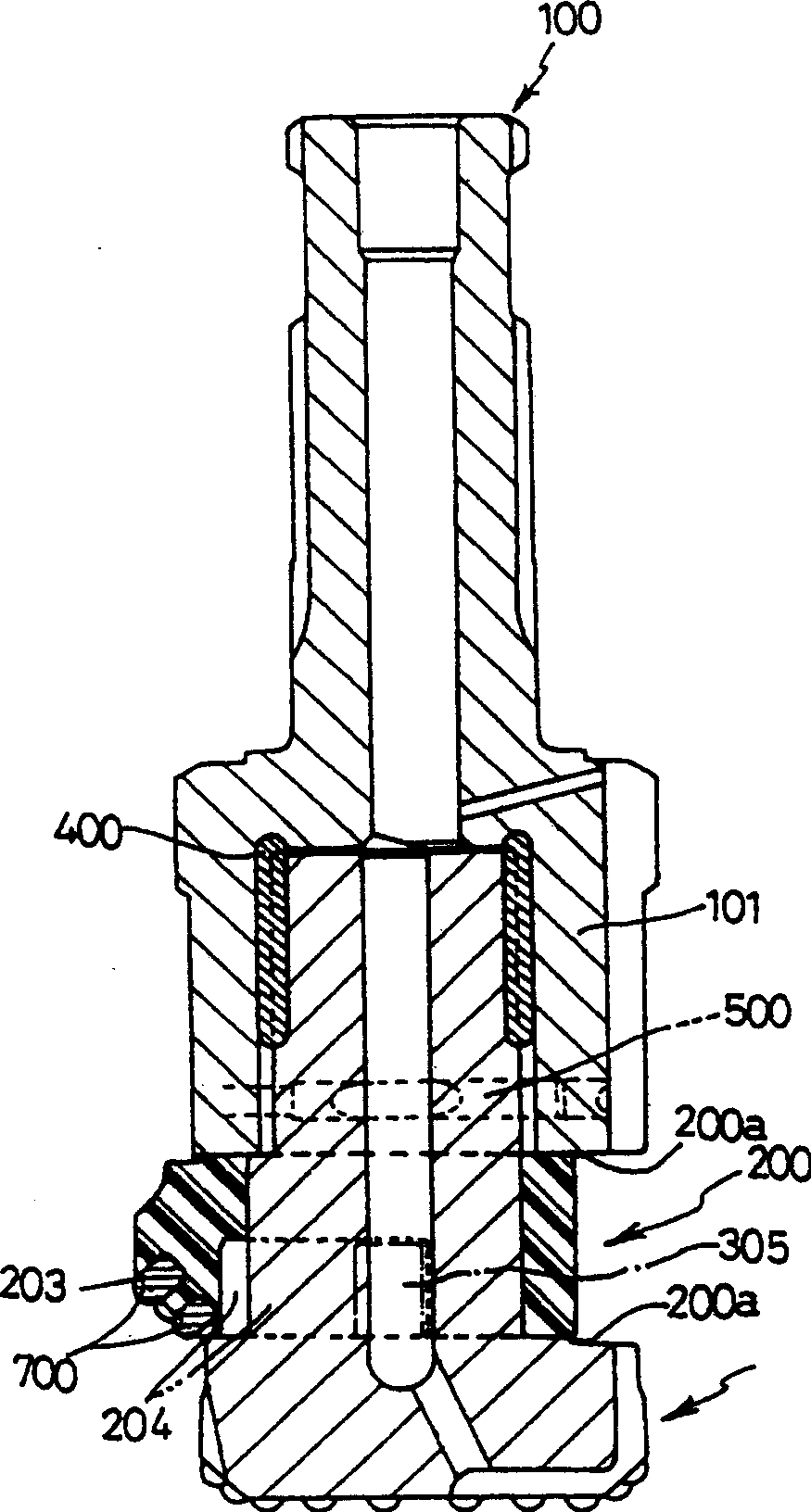

[0017] As shown, the drill sleeve 100 has a body 101 with a pilot connection opening 102 eccentrically formed therein. The body 101 is also provided with vertical pin slots 106 and horizontal pin holes 105, 105' at regular intervals in its inner periphery.

[0018] The pilot bit 300 is connected in the pilot connection opening 102 by inserting the locking pin 500 followed by the rotation stop pin 400, while the expansion bit 200 is connected between the pilot bit 300 and the bit holder 100, thereby basically constituting a hammer drill.

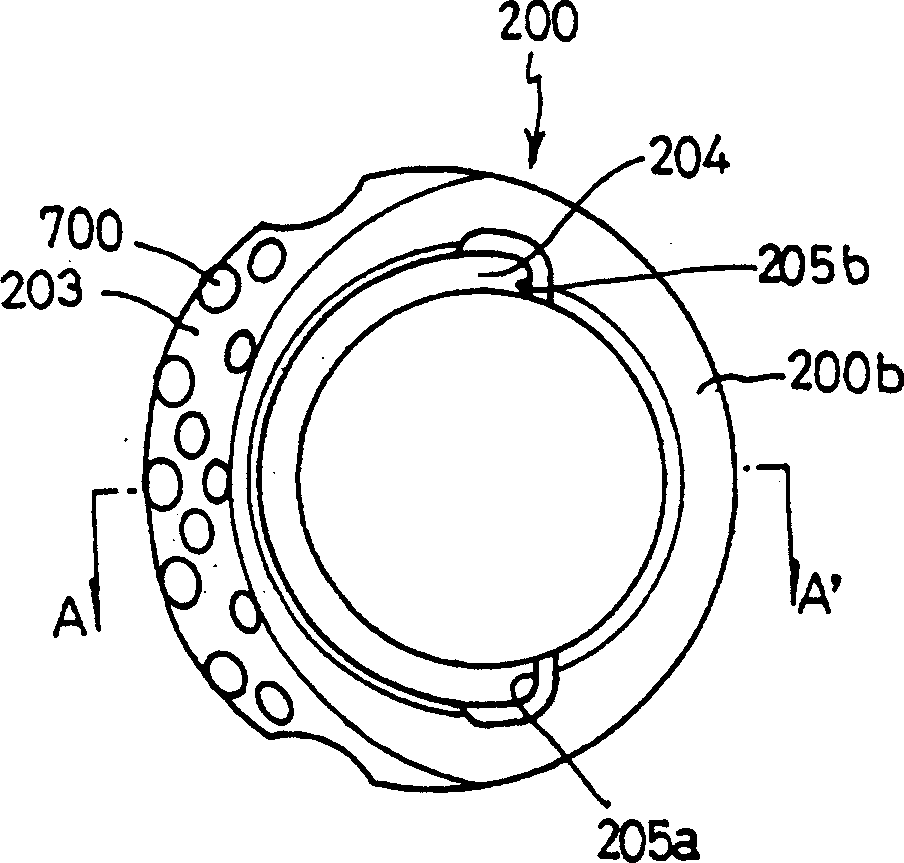

[0019] The expanding drill bit 200 is a half-stroke driving body, which is used to substantially expand a hole through the bit housing 100 and the pilot bit 300 . The expansion drill 200 performs a hole reaming operation as it rotates eccentrically to the guide drill 300 .

[0020] The extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com