Silencer of air inlet for reciprocating type compressor

A muffler and compressor technology, applied in the field of compressor components, to achieve the effect of low cost, simple structure, and suppression of low-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

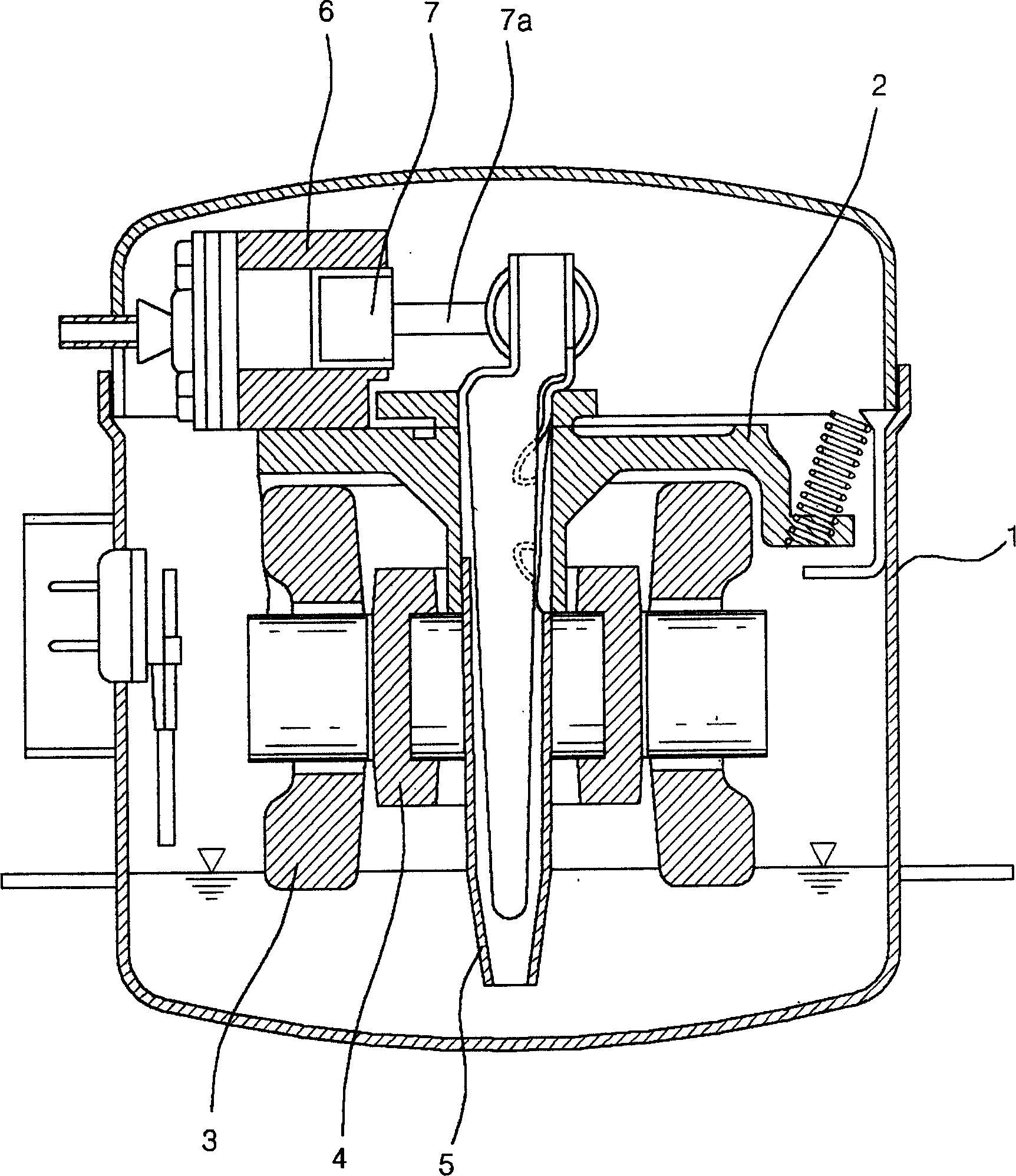

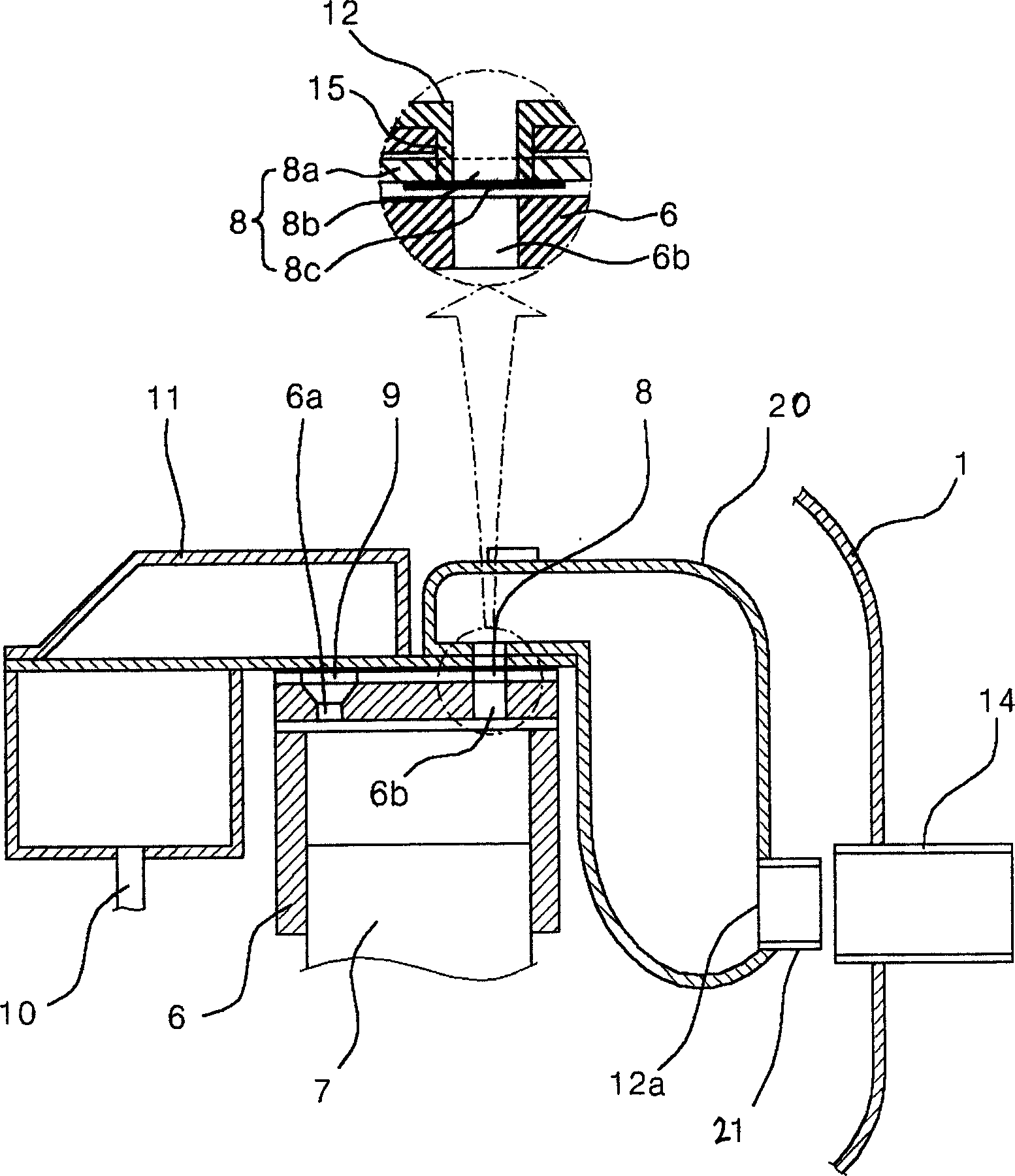

[0031] In the following, the air inlet muffler of the reciprocating compressor of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments:

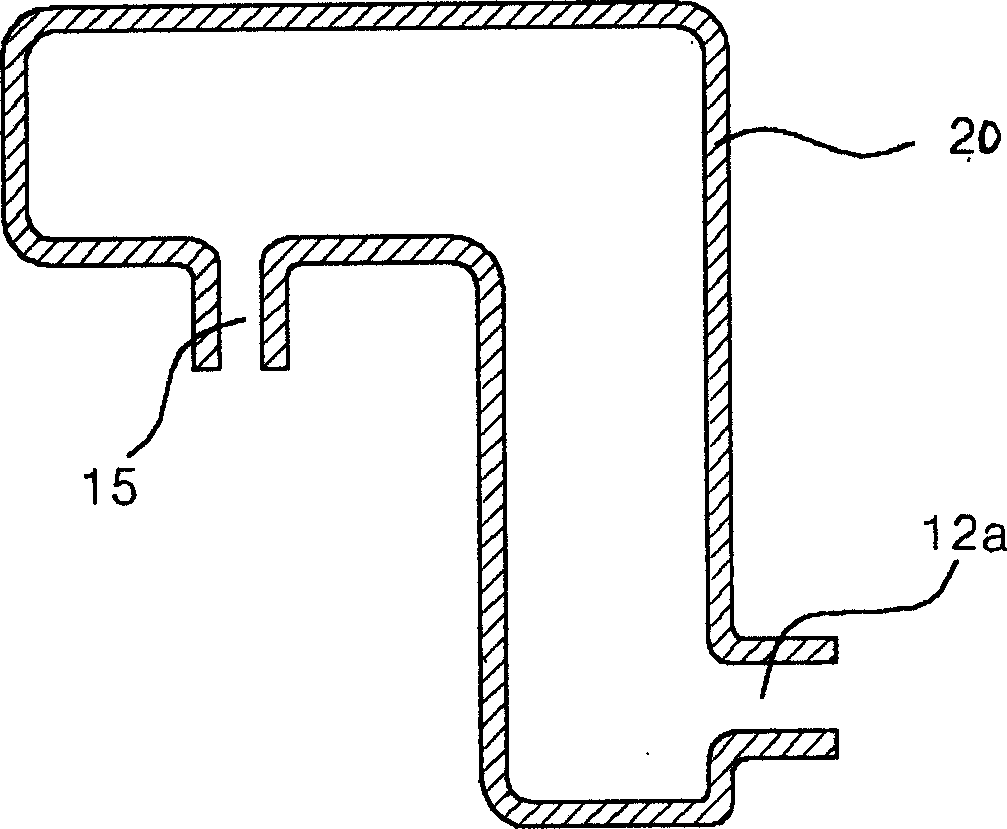

[0032] Such as Figure 4 , Figure 5 As shown, the air intake muffler 20 of the reciprocating compressor of the present invention includes: a muffler body 22, a refrigerant suction pipe 21, a number of deformable parts 23, a tubular resonator 24, and a refrigerant discharge pipe 25; the refrigerant The suction pipe 21 is provided at one end of the muffler body 22, one end of which is a refrigerant suction port 12a that extends into the internal cavity of the muffler body 22, and the other end is connected to a refrigerant pipe 14 that penetrates the airtight container 1 of the compressor; The tubular resonator 24 is arranged in the middle of the internal cavity of the muffler body 22; the deformable component 23 is a plurality of temperature-sensitive alloy material plates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com