Capacitance sensor interface circuit based on frequency switching

A capacitive sensor and interface circuit technology, applied in the direction of logic circuit interface device, logic circuit connection/interface layout, pulse shaping, etc., can solve application limitations, susceptibility to interference by temperature, noise and external factors, and poor accuracy and sensitivity High-level problems, to achieve the effect of reducing processing time, improving work efficiency and response speed, suppressing low-frequency noise and external factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific examples and with reference to the accompanying drawings.

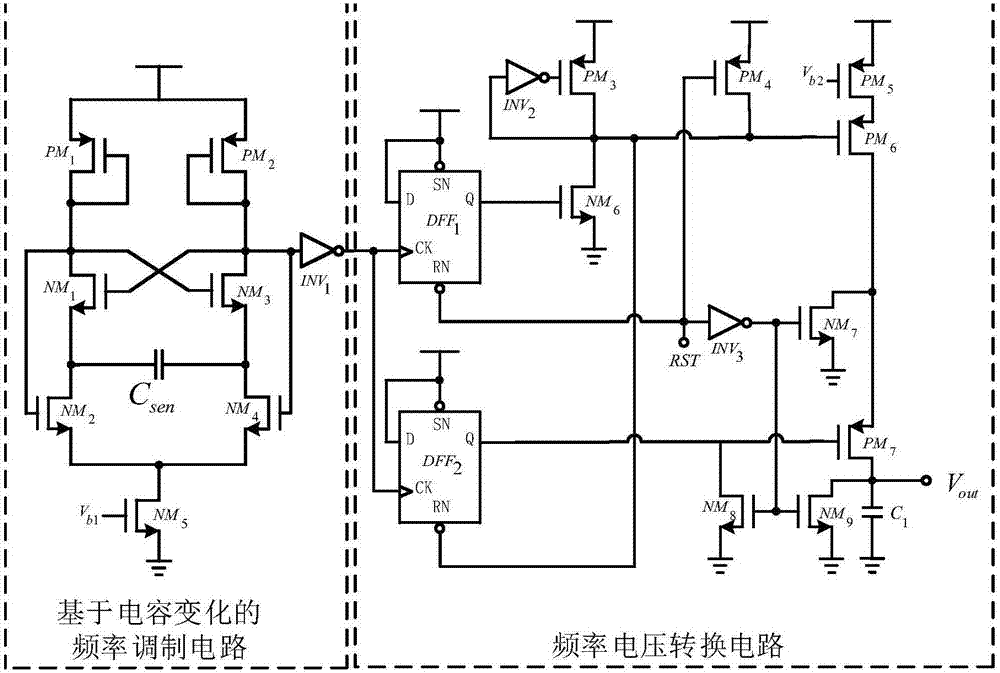

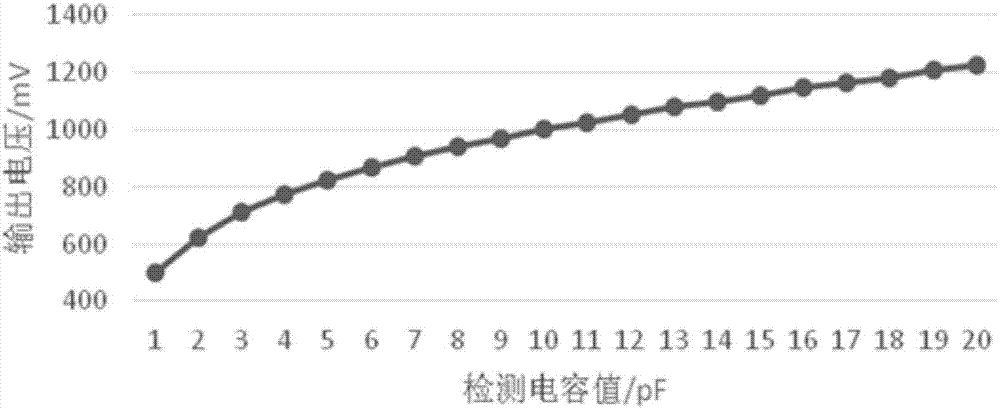

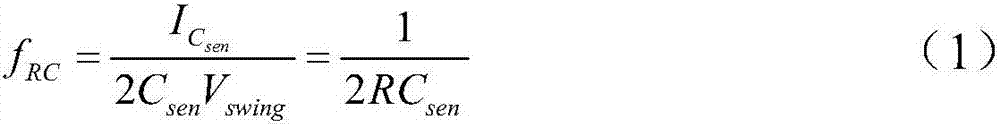

[0017] The present invention proposes a capacitive sensor interface circuit based on frequency conversion, such as figure 1 As shown, it is composed of frequency modulation circuit based on capacitance change and frequency voltage conversion circuit. The frequency modulation circuit based on capacitance variation converts different capacitance values into square waves with different frequencies and a duty cycle of 50%. The frequency-to-voltage conversion circuit converts square waves of different frequencies into corresponding voltage signals after one input signal cycle, so that the generated voltage signal has a certain proportional relationship with the detected capacitance.

[0018] The above-mentioned frequency modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com