Multifunctional fuel gas stove

A gas cooker, multi-functional technology, applied in heating fuel, household appliances, household stove/stove, etc., can solve the problems of inconvenient size adjustment, inability to ensure success, inconvenient use and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

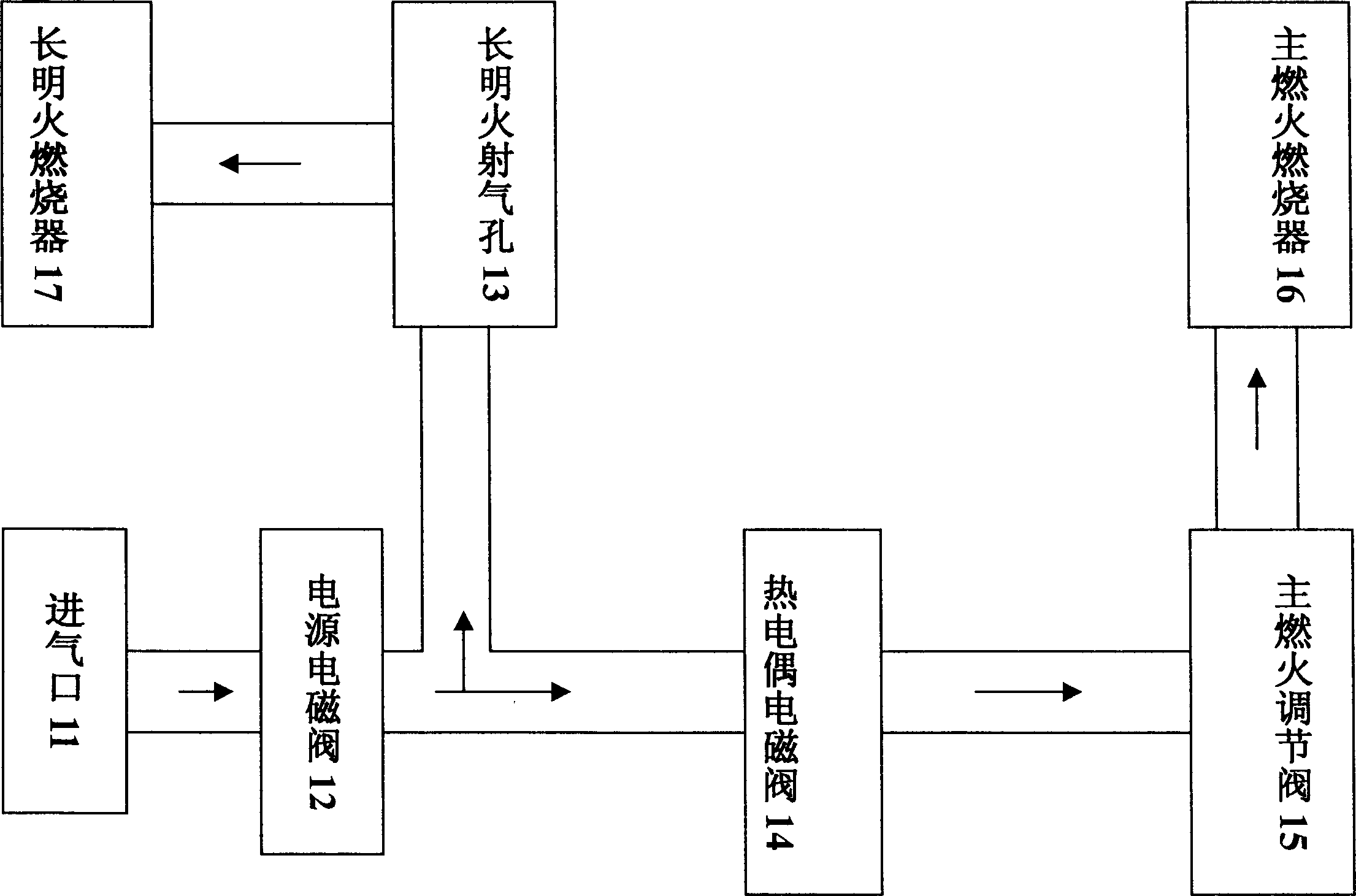

[0018] figure 1 It is the principle block diagram of the gas circuit of the whole cooker of the present invention, wherein the structure of the main ignition regulating valve 15 can be found in the application number 02111025.5 Figure 5 shown. It can be seen from the figure that the power solenoid valve 12 is arranged on the channel of the gas cooker air inlet 11, and the long open flame jet hole 13 is in the shape of a circular vent hole, and is arranged on the first branch road at the rear end of the power solenoid valve 12, quantitatively controlled The size of the constant flame fire, the thermocouple solenoid valve 14 is arranged on the second branch of the power supply solenoid valve 12 rear end;

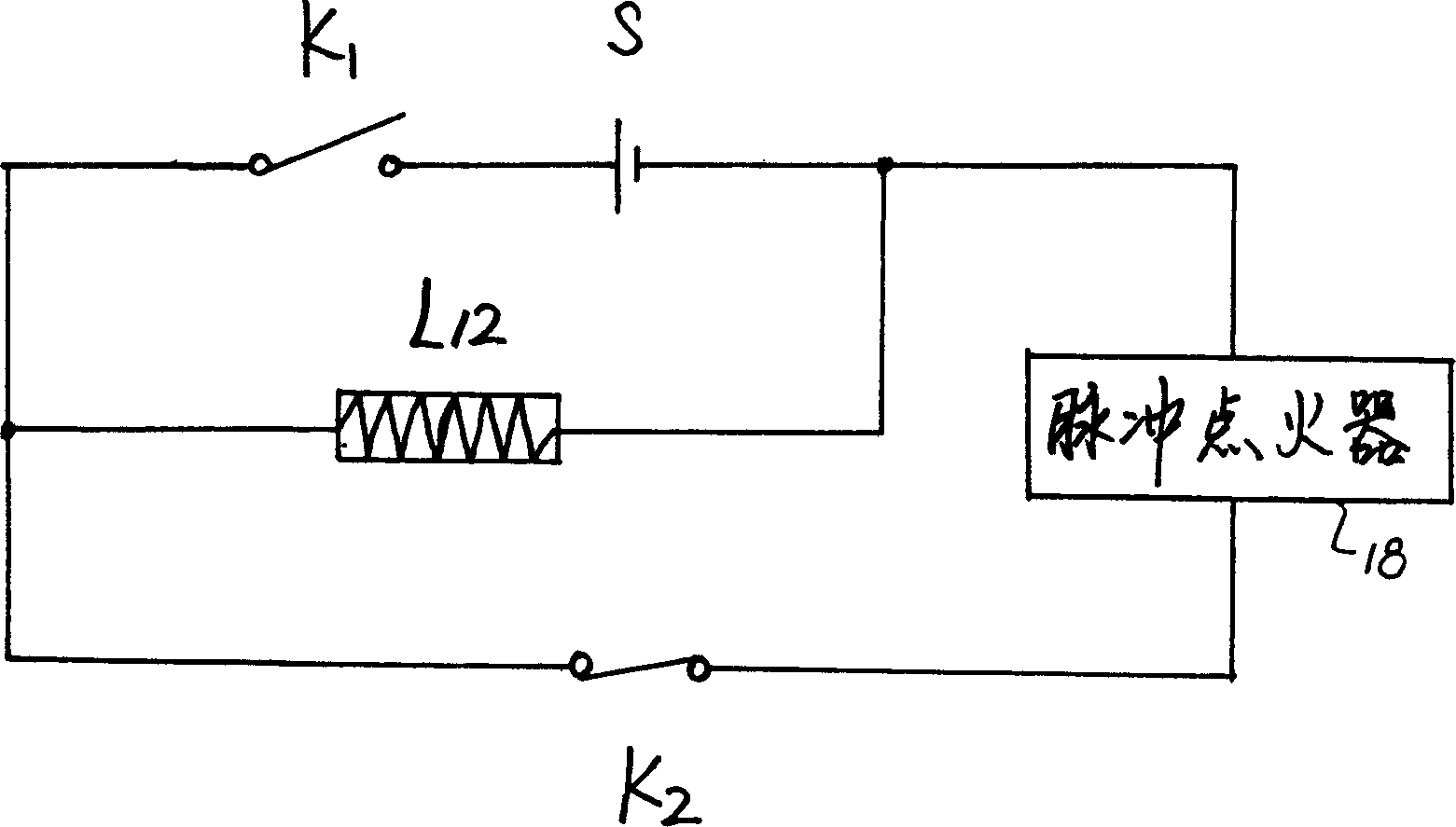

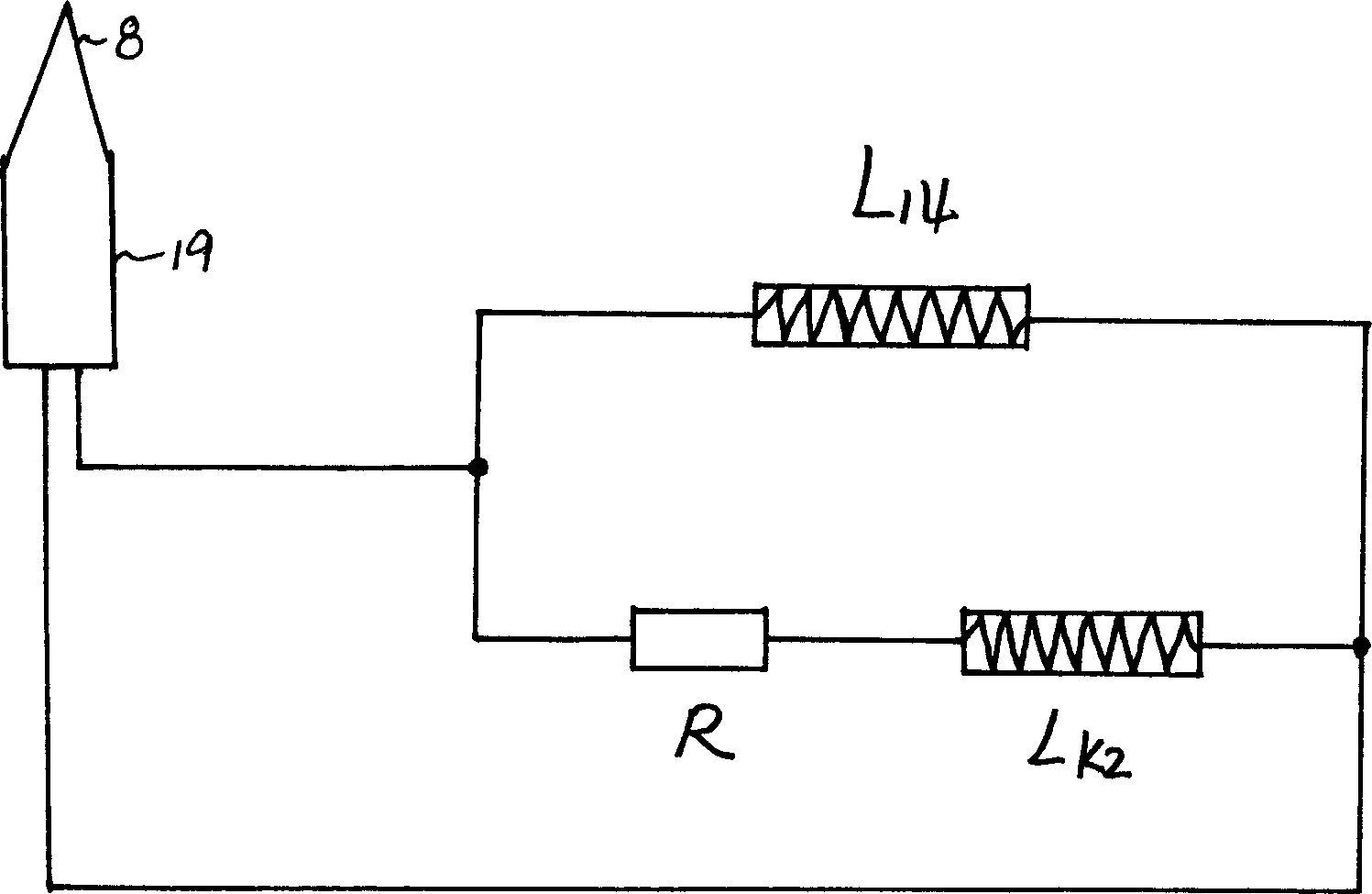

[0019] figure 2 with image 3 It is the circuit diagram of the control gas path and pulse ignition. figure 2 The first circuit composed of the medium power supply S-linkage switch K1-the inductance coil L12 of the power solenoid valve is the control circuit for controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com