Die-casting die of 3D columnar fin type radiator and its die-casting method

A technology for die-casting molds and radiators, which is applied in the field of manufacturing methods and the molds used, can solve the problems that are not suitable for the processing of columnar radiators, and achieve the effects of fast connection speed, elimination of gaps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The die-casting three-dimensional finned columnar radiator includes the following steps:

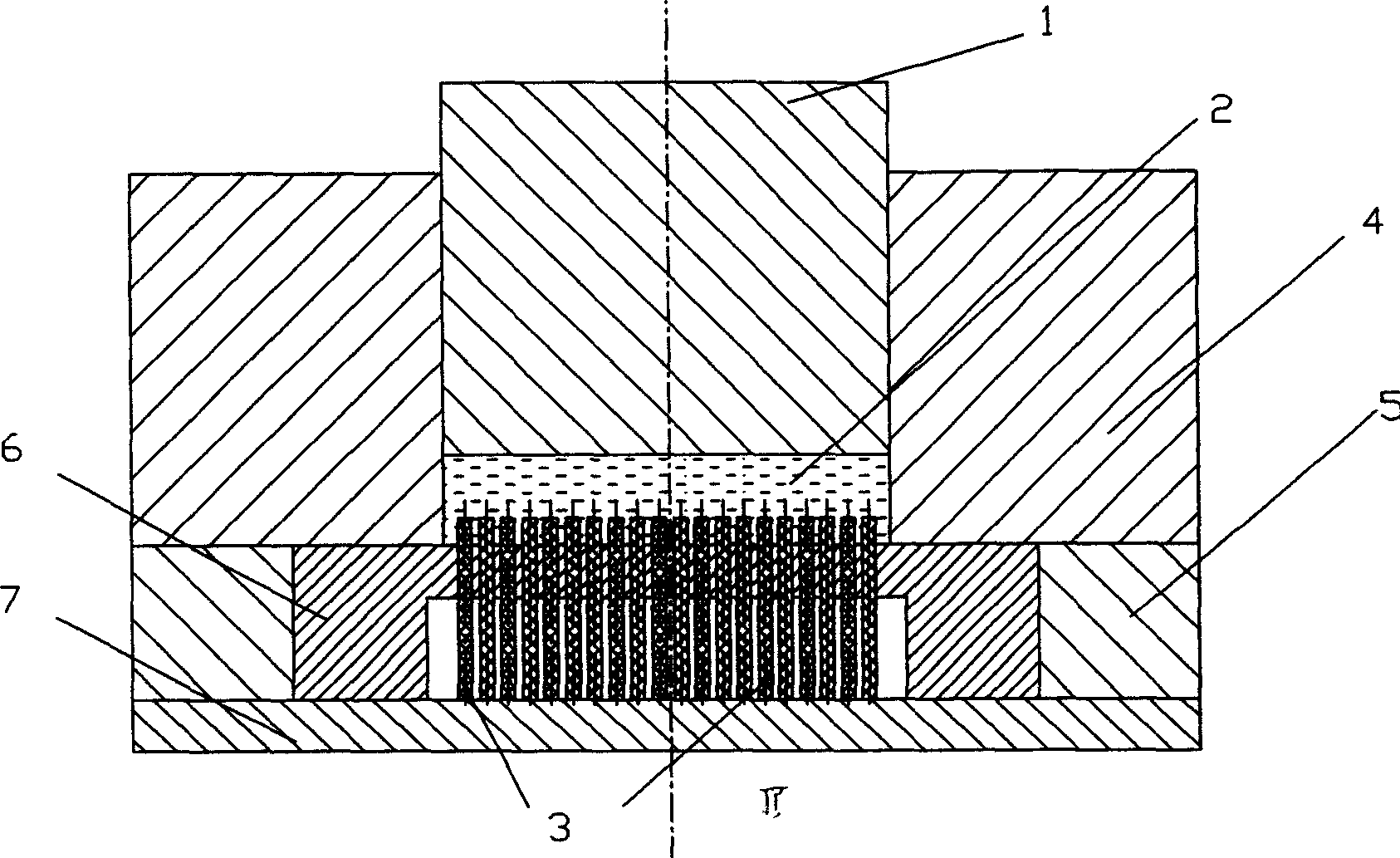

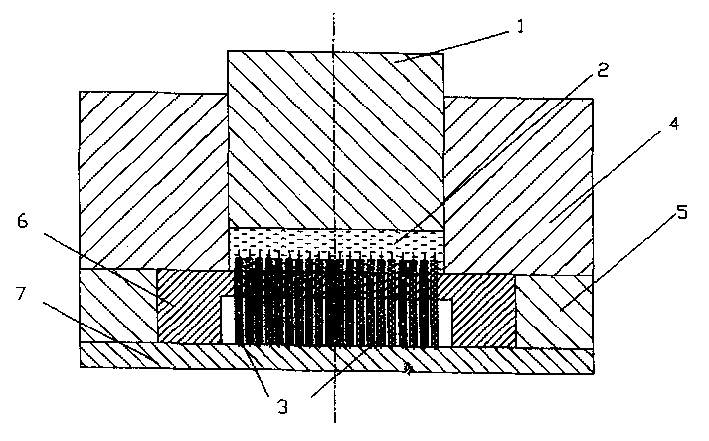

[0036] (1) Insert the three-dimensional finned column into the figure 1 In the molding die 6 of the shown die-casting mold, and keep it can be plugged freely in the model;

[0037] (2) metal powder is filled in the cavity of molding die 6;

[0038] (3) Drive the ejector pin 1 to press down through the hydraulic press, and the pressure is 5MPa to realize the die-casting connection of the CPU radiator;

[0039] (4) Heating the molding die 6 after die-casting, the temperature is controlled at 1000° C. to sinter the metal powder inside;

[0040] (5) The three-dimensional finned columnar radiator is demoulded from the molding die 6, and finally polished and trimmed.

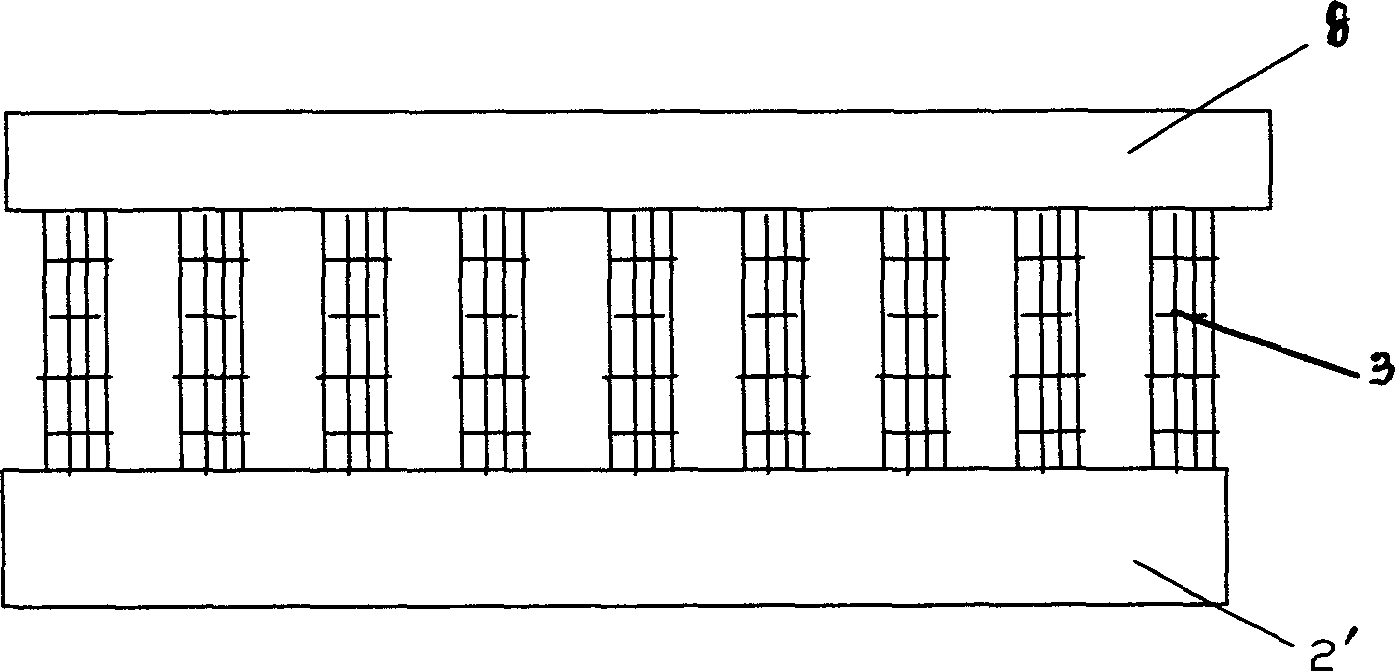

[0041] The three-dimensional finned columnar heat sink structure is demoulded, such as figure 2 As shown, several three-position finned columns 3 are casted between the fan 8 and the base plate 2 ′.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap