Image sensor assembly and its mfg. method

An image sensor and component technology, applied in image communication, electrical solid-state devices, semiconductor devices, etc., can solve the problems of reducing the optical performance of the lens and expanding the refraction angle of the incident beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

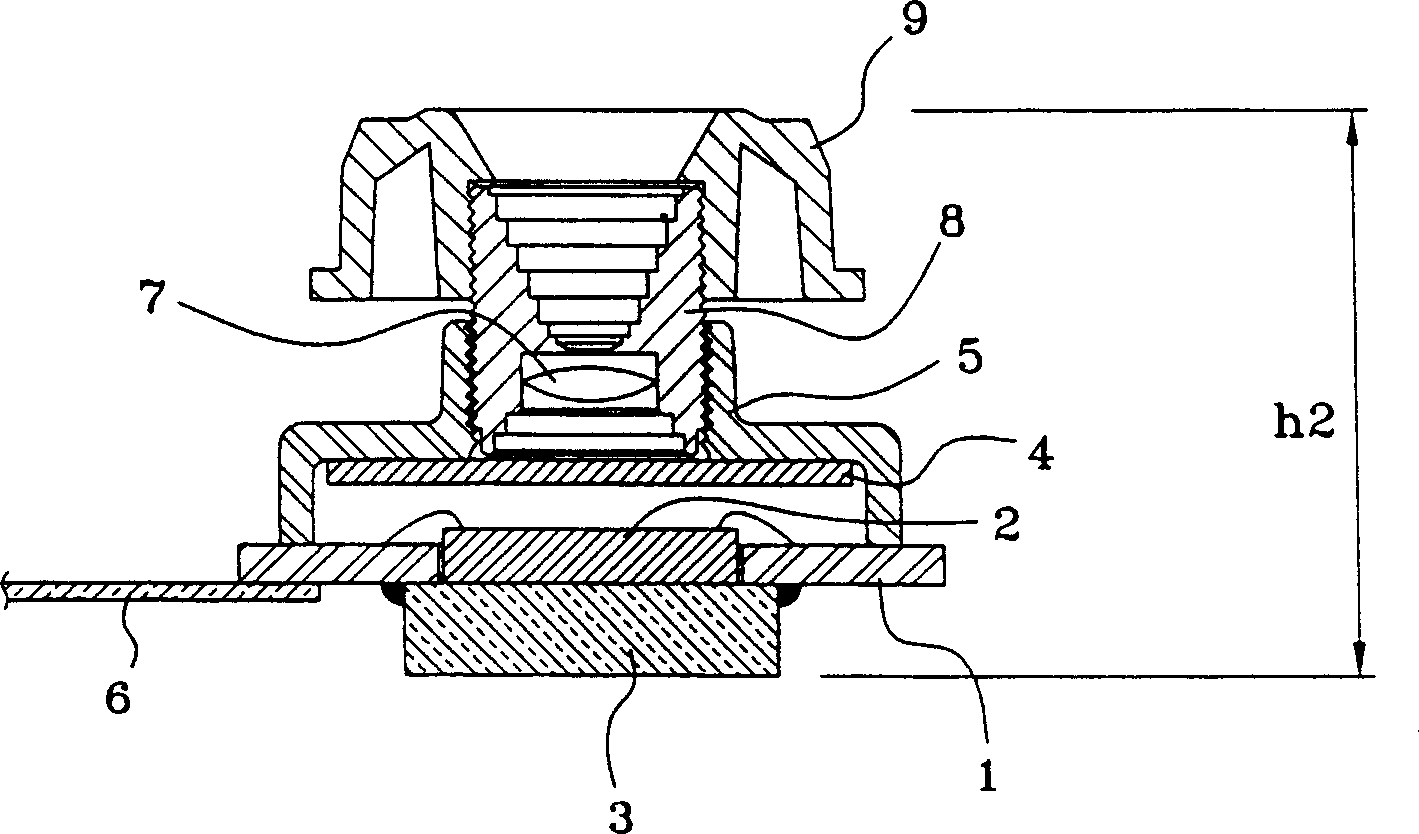

[0029] According to the second embodiment of the present invention, the camera assembly includes: an image sensor assembly, a housing 15 , a hard package 18 , a lens 17 , a knob 19 , a filter 14 and an FPCB 16 .

[0030]A hard encapsulation 18 that is threaded together is located inside the housing 15, covering the upper portion of the image sensor assembly, while a lens 17 is located within the hard encapsulation. Similar to the first embodiment, the knob 19 covers one end of the hard package, the filter 14 is located inside the housing, and the FPCB 16 is connected to the backside of the substrate 11 . At this time, the height h3 of the casing 15 of the camera module is higher than the height h2 of the casing in the first embodiment. However, the height of the camera assembly according to the second embodiment of the present invention is lower than that of the assembly in the first embodiment because the structure composed of the EMC layer 20 for sealing the back side of the...

no. 3 example

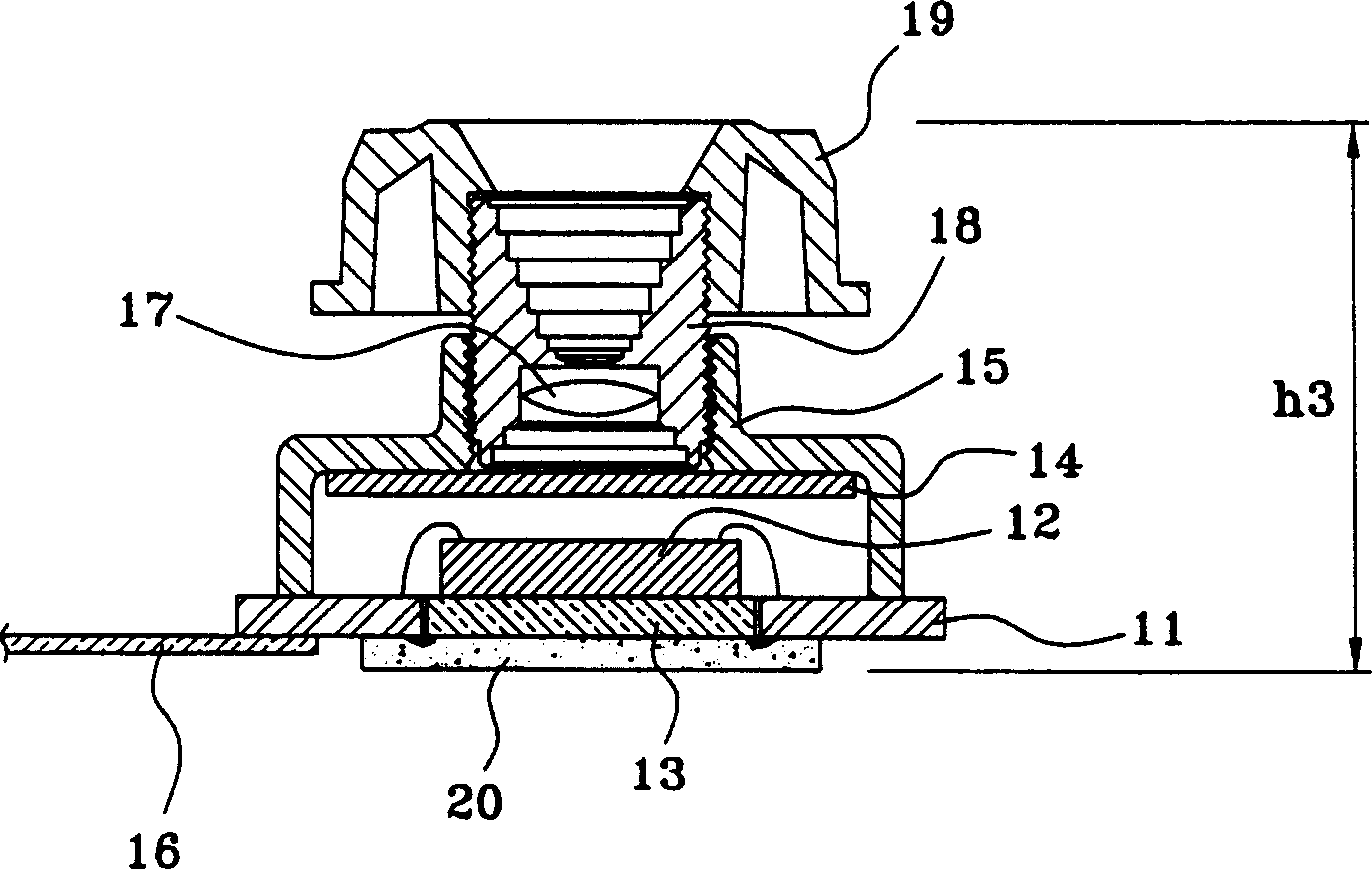

[0033] According to a third embodiment of the present invention, an image sensor assembly includes: a substrate 21 with a hole in its center; an FPCB 26 attached to the backside of the substrate 21; an ISP package 23 attached to the backside of the FPCB 26; and an image sensor 22, installed in the hole of the substrate 21.

[0034] Additionally, a camera assembly is provided. The camera assembly includes: an image sensor assembly according to the third embodiment; a housing 25 covering the upper part of the image sensor assembly; a hard package 28 engaged with threads and located inside the housing; a lens 27 located in the hard package the inner side; the knob 29, which covers one end of the hard case; and the filter, which is located on the inner side of the housing.

[0035] The process of manufacturing the image sensor assembly according to the third embodiment includes the steps of: forming a hole in the center of the substrate 21; attaching the FPCB 26 to the backside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com