Chemical lighting bar and working method thereof

A chemiluminescence and shell technology, applied in the direction of light sources, fluorescence, lighting and heating equipment, etc., can solve the problems of easy wrinkling of adhesive tape and easy falling off of luminescent stick ink, so as to avoid dissolution and enhance the fun effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

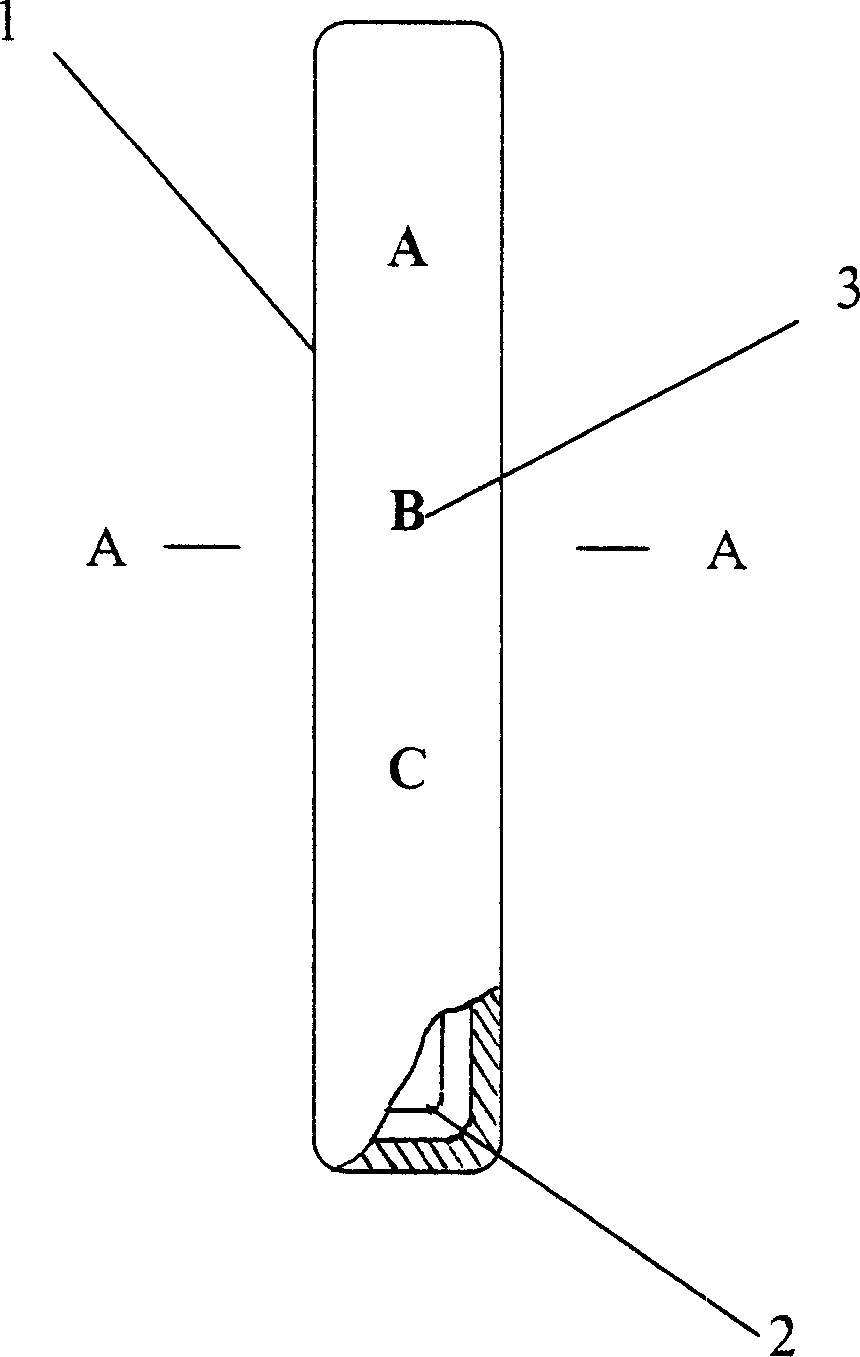

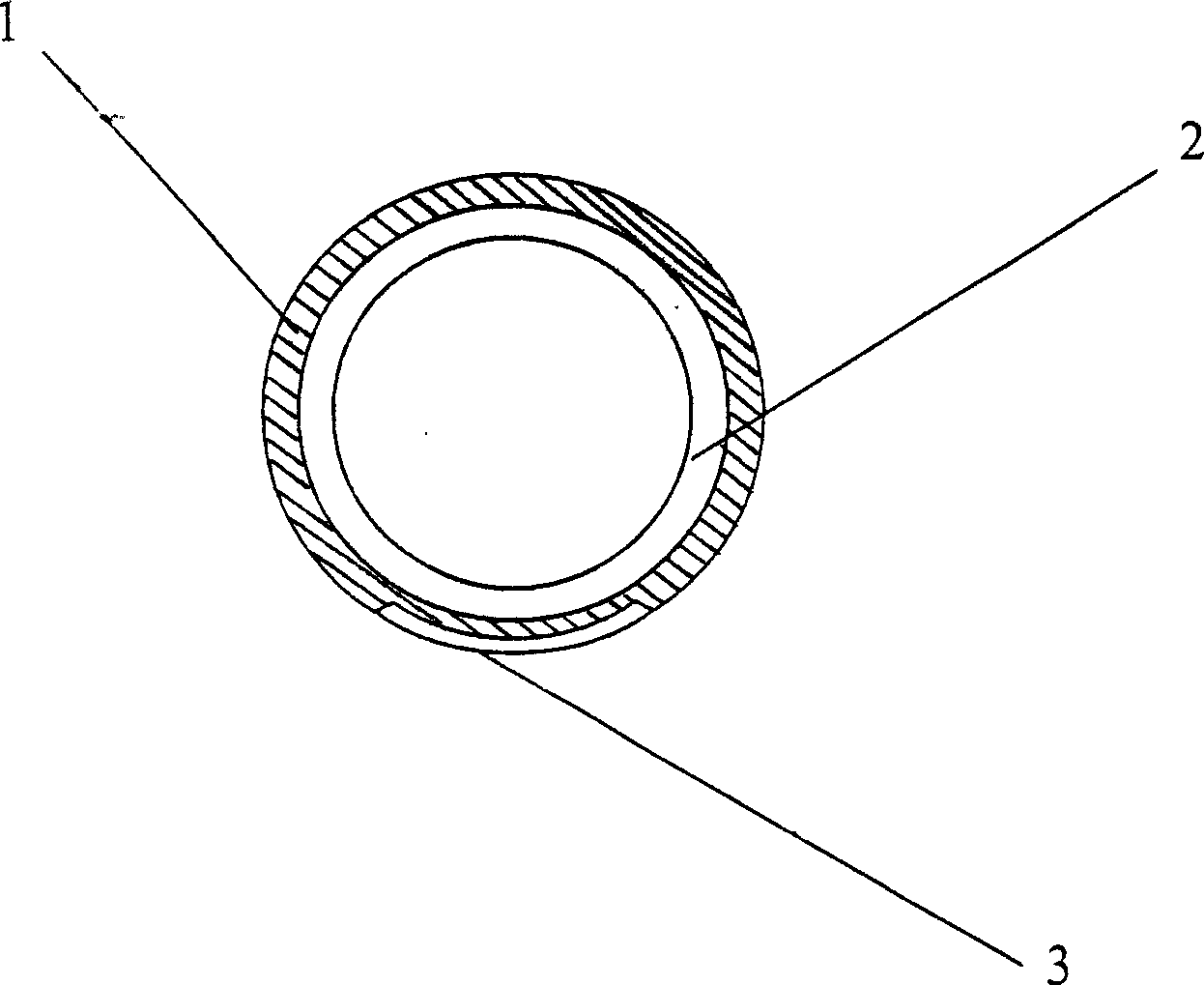

[0020] see figure 1 1 in the figure is the shell, which is made of elastic, transparent or translucent plastics, such as polypropylene, polyethylene, polyester, polycarbonate and other materials, preferably high-pressure polyethylene, and 2 is thin sealing glass. A chemiluminescent agent is installed between 1 and the sealed glass tube 2, and another chemiluminescent agent that can react with the chemiluminescent agent outside is installed in the sealed glass tube 2, and 3 is a pattern layer. The pattern in this embodiment Layer is ABC words, and its color can be one or more than one. The thickness of the pattern layer 3 is between 0.0001mm-2mm. figure 2 yes figure 1 A-A sectional view of , that is, a schematic cross-sectional view of the chemiluminescent rod of the present invention.

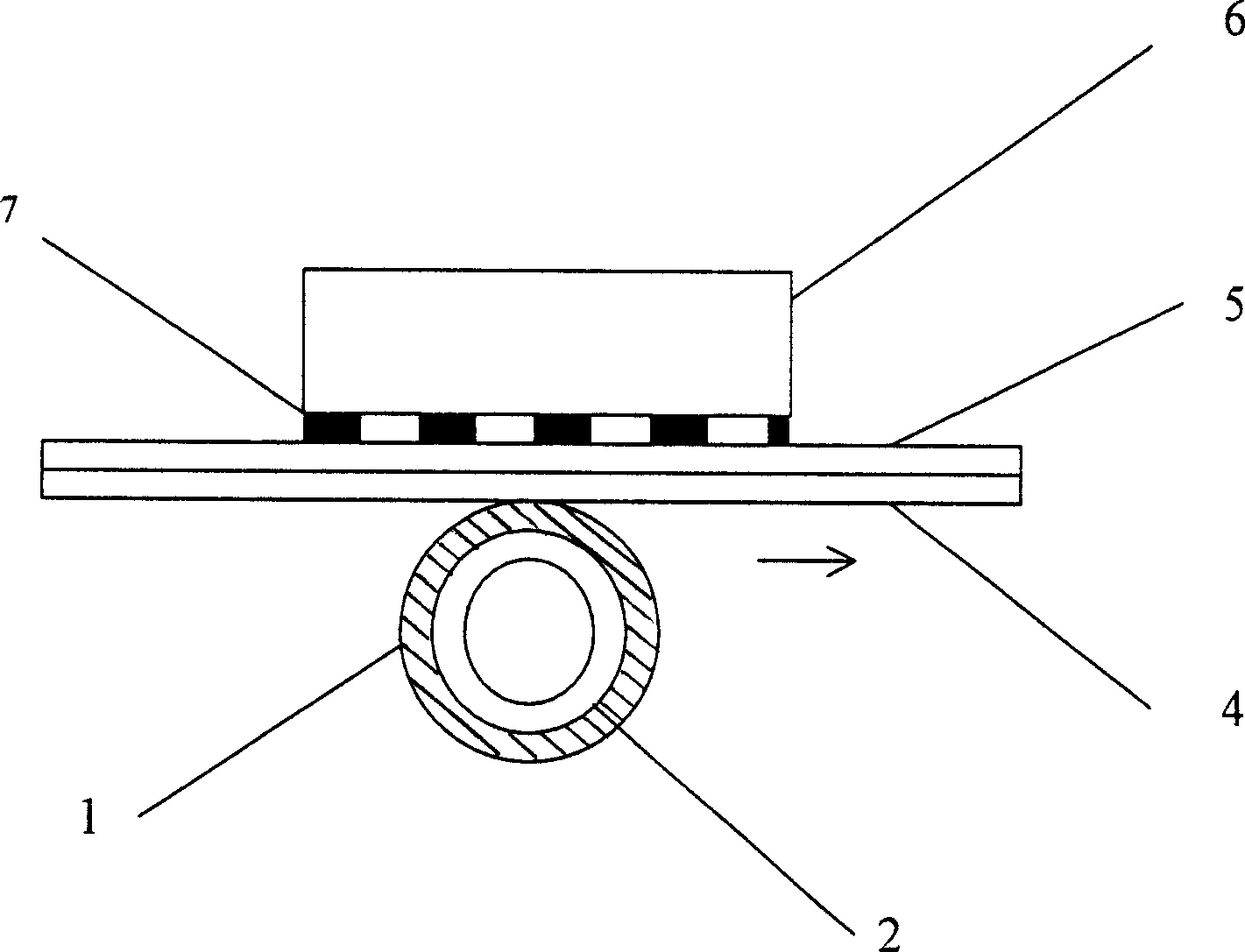

[0021] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com