Composition for optical films, base having optical film, molded body and method for producing molded body

A technology of optical film and composition, applied in chemical instruments and methods, optics, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

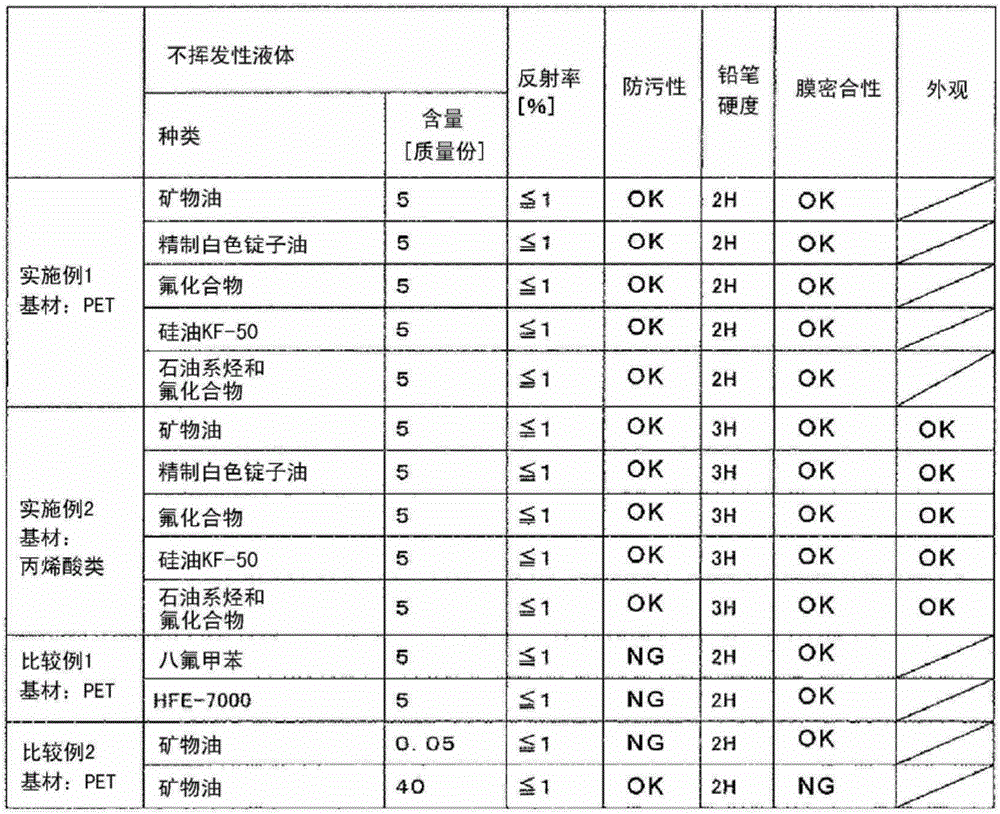

[0112] As a substrate, a colorless and transparent PET substrate (manufactured by Toray Corporation, trade name LUMIRROR U34) was prepared.

[0113] In addition, as a thermosetting resin composition containing silica-based hollow fine particles, a thermosetting resin, and a volatile solvent, ELCOM MA-1021SIC manufactured by Nikke Catalytic Chemicals Co., Ltd. was prepared. To this composition, the following nonvolatile liquids were added to prepare various antireflection film compositions.

[0114] 1) Mineral oil (manufactured by Johnson & Johnson, baby oil): The vapor pressure at 25°C is lower than the detection limit, the boiling point is 250°C or higher, the refractive index is about 1.46, and the viscosity at 23°C is 0.6 Pa·s.

[0115] 2) Refined white spindle oil (manufactured by AZ Co., Ltd., part number 035): the vapor pressure at 25°C is lower than the detection limit, the boiling point is 250°C or higher, and the refractive index is about 1.46.

[0116] 3) Fluorine c...

Embodiment 2

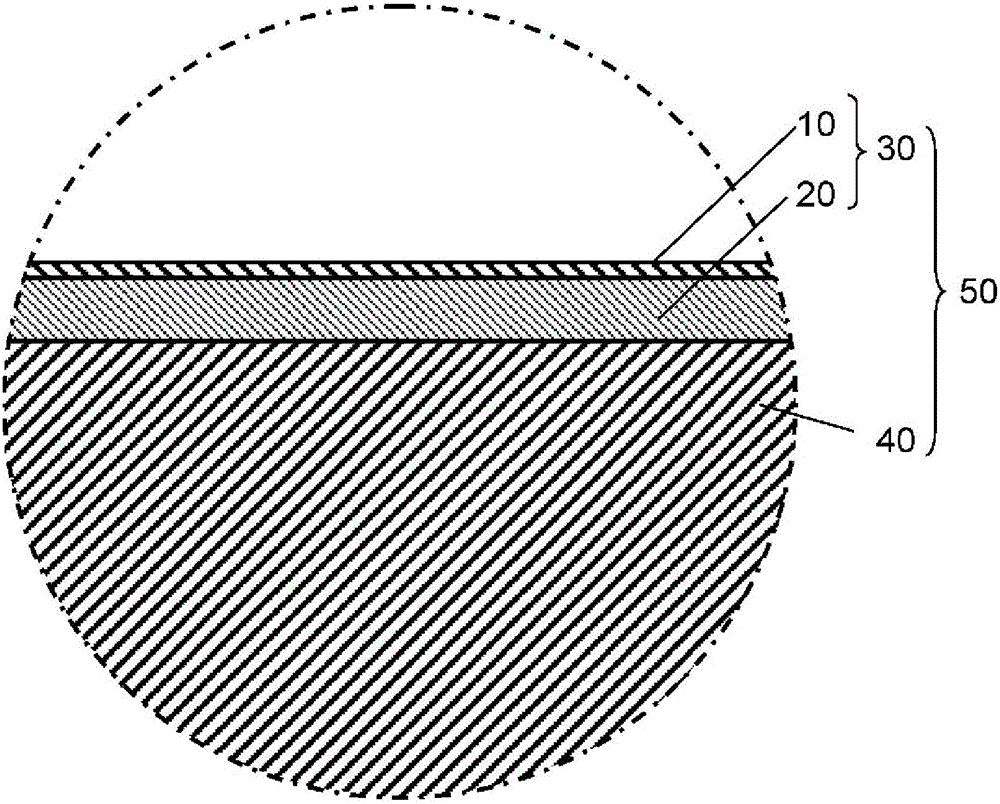

[0122] As the substrate, a colorless and transparent base material (manufactured by Teijin Corporation, trade name NJ-5100 (acrylic / polycarbonate resin film: hereinafter, APC film) was used. Until the drying treatment, it was performed in the same manner as in Example 1, and the The surface of the film forms a dry film. In the dry film, the thermosetting resin is not fully cured. The APC film that has formed the dry film is put into the mold, and the back side of the APC film (the side that does not form the film) is injection-molded with poly Carbonate resin, the molded body is integrally molded on the back of the APC film to produce a molded body with an anti-reflection film. At this time, during the molding, the APC film is deformed along the mold, and at the same time, the thermosetting resin is completely cured in the dry film To form an anti-reflection film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com