Black magnetic fingerprint display powder using graphene-modified stearic acid and its preparation

A technology of graphene modification and stearic acid, which is applied in the fields of application, medical science, diagnosis, etc., can solve the problems of lack of lubrication, etc., and achieve the effects of good fingerprint display, easy preservation, and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

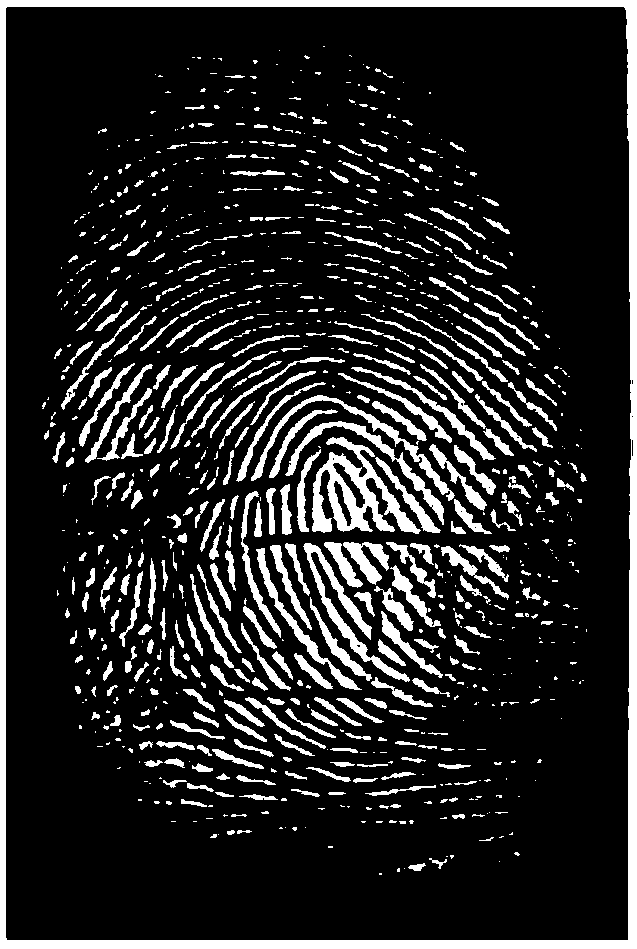

[0036] Magnetic powder Fe 3 o 4 Powder (the mesh number is controlled between 800-5000 mesh), stearic acid powder and graphene (the mesh number is controlled between 6000-10000 mesh) are mixed according to the ratio of 32:16:1 by weight, and ball milled. The parameters of the ball milling process are: the ratio of ball to material is 3:1, the speed is 120 rpm, and the time is 30 minutes. The powder obtained after ball milling was sieved with a 100-mesh sieve to obtain the desired powder, and dried in an oven at 50° C. for 2 hours.

[0037] The resulting black magnetic fingerprint display powder on the iron plate covered with blue paint shows the effect of fingerprint display on fresh fingerprints. figure 1 shown.

[0038] The resulting black magnetic fingerprint display powder on the glass surface for fingerprint display of fresh fingerprints is shown in the figure figure 2 shown.

[0039] The resulting black magnetic fingerprint display powder on the black electrostatic...

Embodiment 2

[0044] Magnetic powder Fe 3 o 4 Powder (the mesh number is controlled between 800-5000 mesh), stearic acid powder and graphene (the mesh number is controlled between 6000-10000 mesh) are mixed according to the weight ratio of 40:15:2, and then ball milled. Ball milling process The parameters are: the ratio of ball to material is 6:1, the speed is 250 rpm, and the time is 20 minutes. The powder obtained after ball milling was sieved with a 100-mesh sieve to obtain the desired powder, and dried in an oven at 50° C. for 2 hours.

[0045] The black magnetic fingerprint display powder obtained in this example has a clear display effect and is easy to preserve.

Embodiment 3

[0047] Magnetic powder Fe 3 o 4 Powder (the mesh number is controlled between 800-5000 mesh), stearic acid powder and graphene (the mesh number is controlled between 6000-10000 mesh) are mixed at a weight ratio of 60:25:5, and then ball milled. Ball milling process The parameters are: the ratio of ball to material is 4:1, the speed is 150 rpm, and the time is 25 minutes. The powder obtained after ball milling was sieved with a 100-mesh sieve to obtain the desired powder, and dried in an oven at 50° C. for 2 hours.

[0048] The black magnetic fingerprint display powder obtained in this example has a clear display effect and is easy to preserve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com