Shoe having a fabric outsole and manufacturing process thereof

A technology for fabrics and shoe outsole, applied in textiles and papermaking, shoe soles, shoe uppers, etc., can solve the problem of not realizing the price benefit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

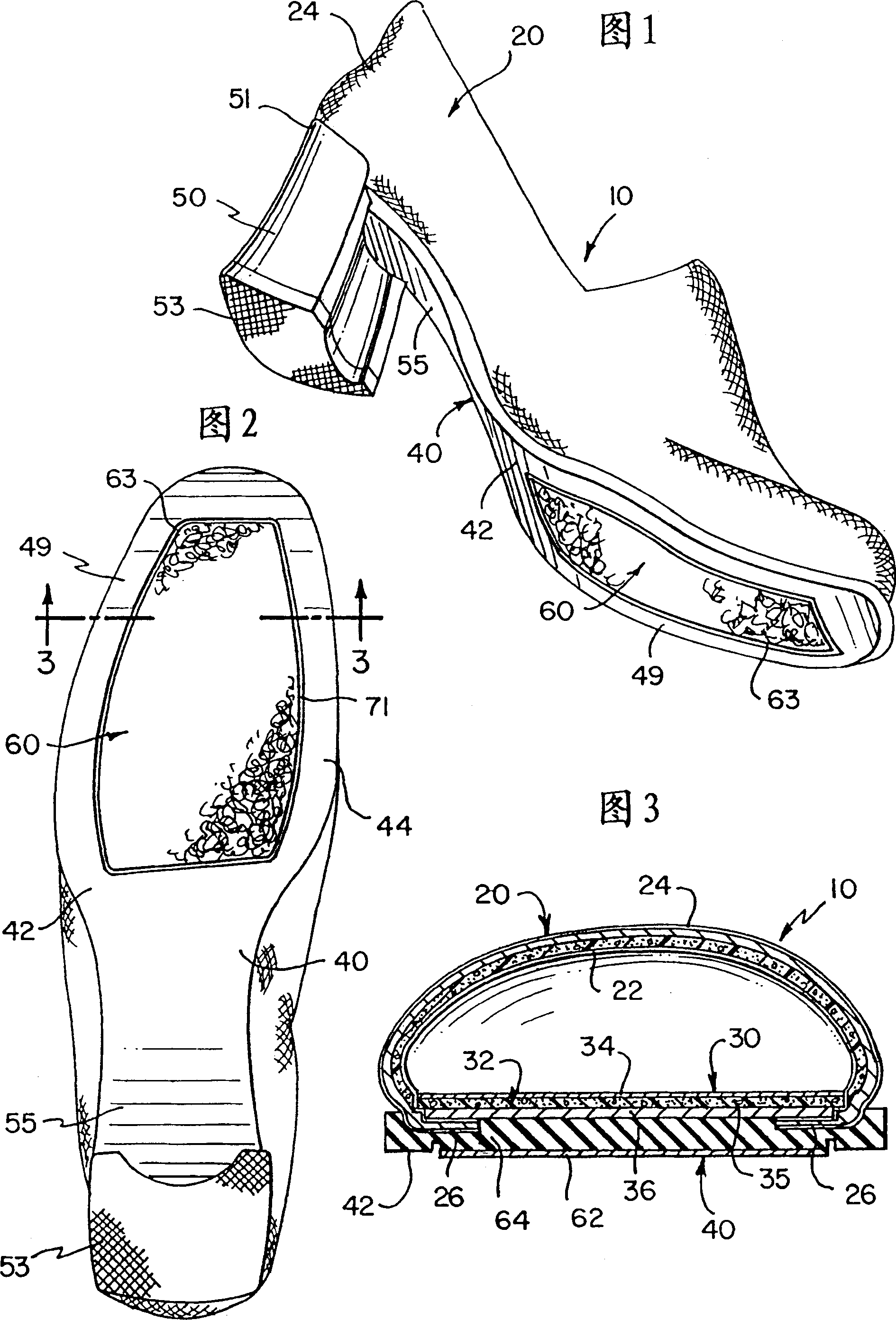

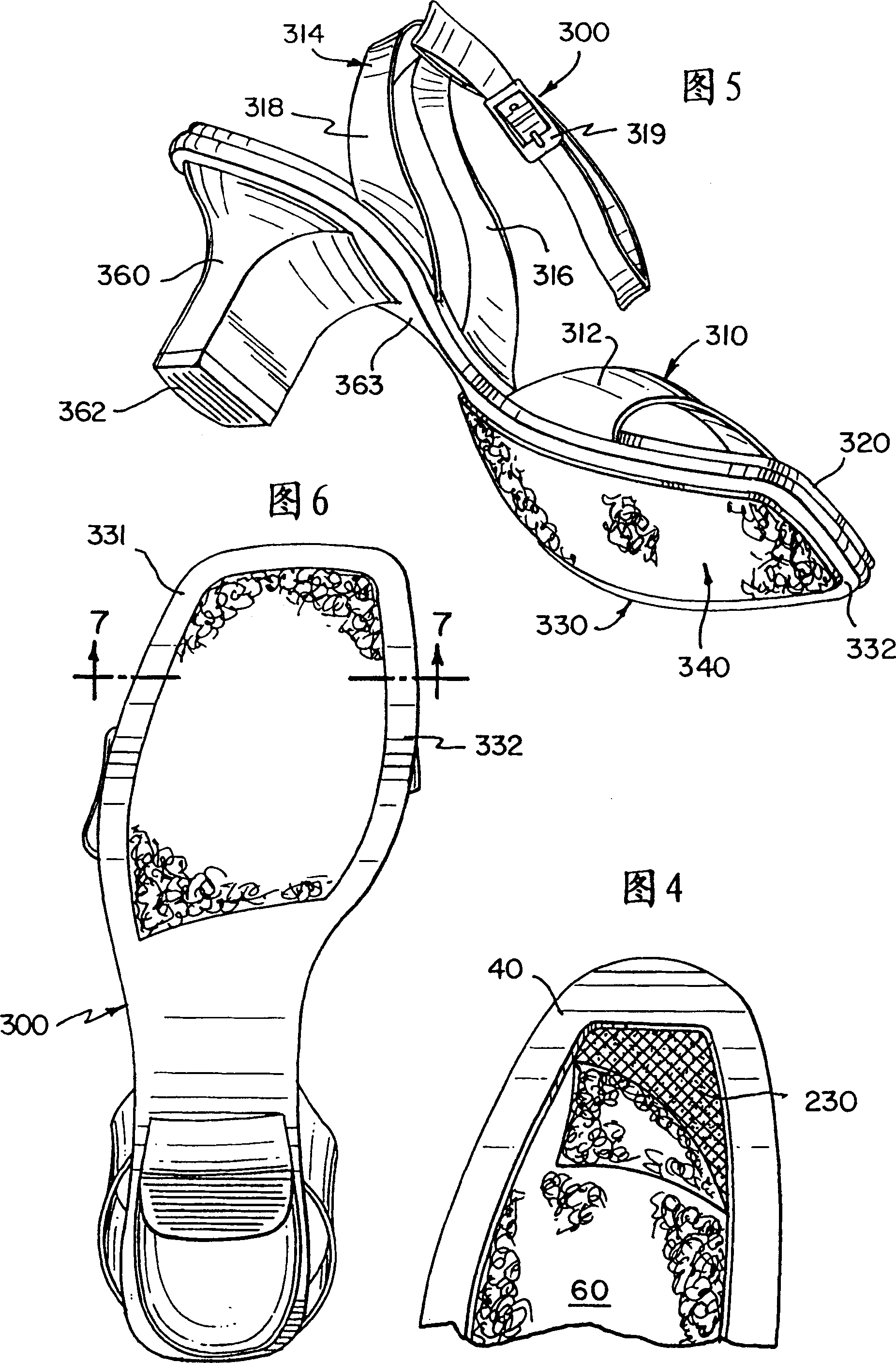

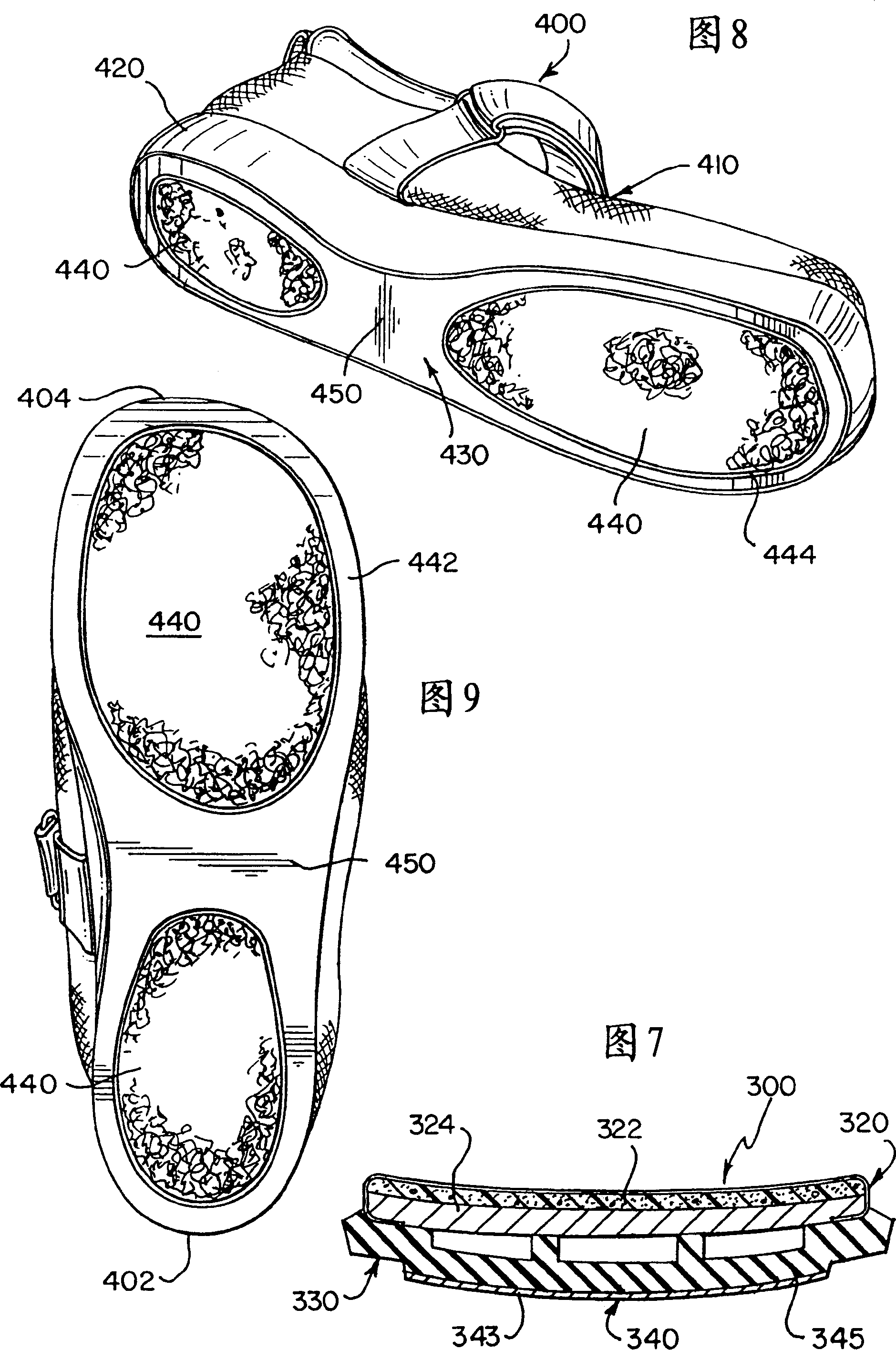

[0038] The invention will first be described with reference to FIGS. 1-4. FIG. 1 depicts an example version of a shoe 10 having an upper 20 , a lower portion 30 attached to the upper 20 , and an outsole 40 attached to the lower portion 30 . The shoe 10 is of a style commonly worn by women on the workplace and social occasions. The style and nature of shoe 10 are illustrative only, and it is understood that the present invention is applicable to a wide variety of shoe types, including, but not limited to, men's, women's, and children's shoes.

[0039] FIG. 3 is a cross-sectional view of shoe 10 showing the shoe structure in great detail. Upper 20 includes a layer of soft padded base material, such as fabric-backed foam 22, on the interior of shoe 10 for resiliently fitting the wearer's foot. In this way, the function of the fabric-backed foam 22 is to add a layer of padding to the wearer's foot during use to provide support to the foot and reduce the impact of the foot and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com