Micro-powder remover

A particle and vacuum container technology, applied in the direction of electrostatic cleaning, cleaning methods and appliances, ion implantation plating, etc., can solve the problems of reduced operating rate, huge, particle generation, etc., and achieve the effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An apparatus for removing particles according to the present invention will be described in detail with reference to the accompanying drawings.

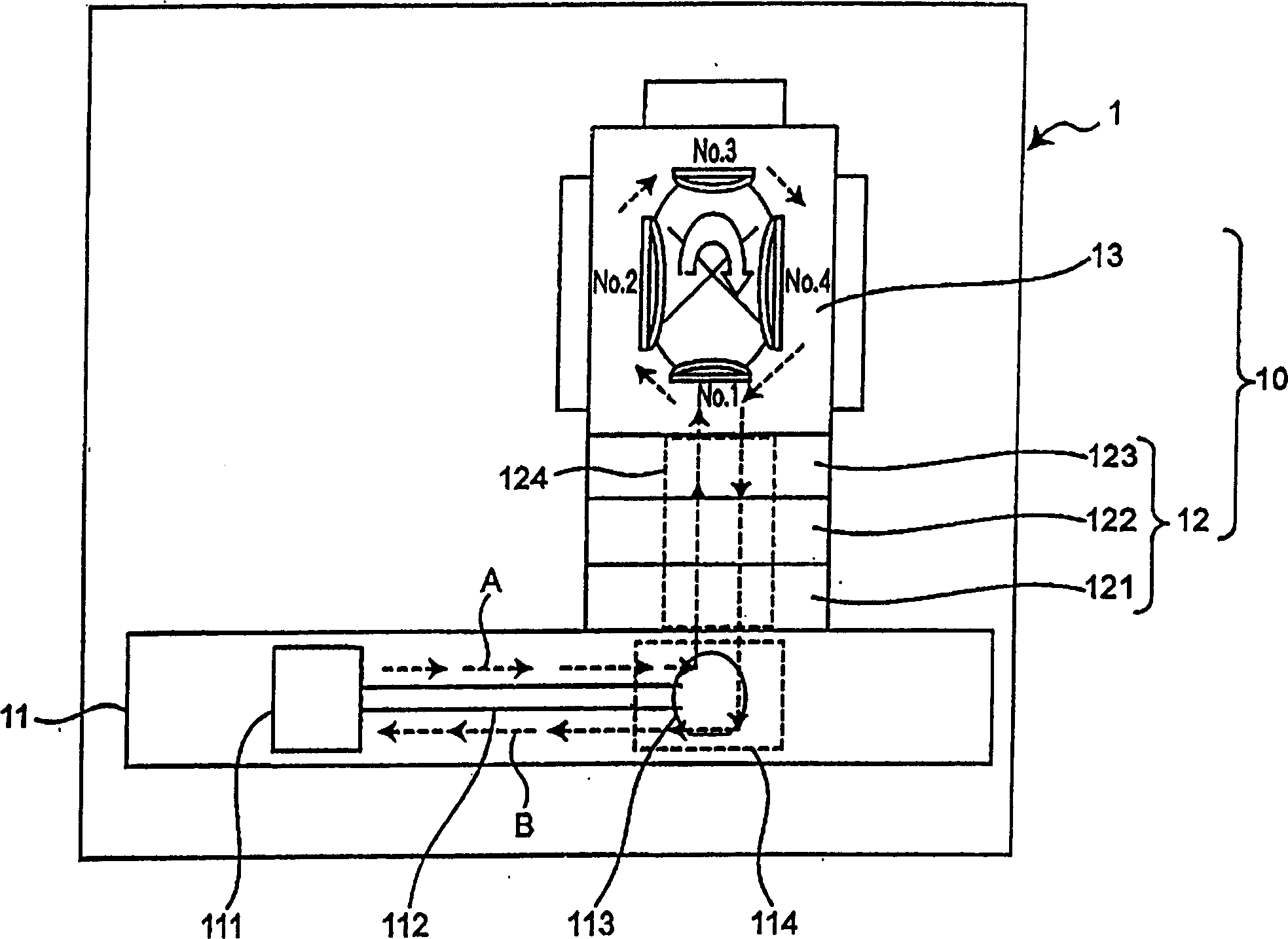

[0028] figure 1 is a plan view schematically illustrating the configuration of a sputtering apparatus including an apparatus for removing particles according to an embodiment of the present invention.

[0029] The sputtering apparatus 1 includes a transfer unit 11 for transferring a wafer; a pressure buffer unit 12 and a processing chamber 13 . The pressure buffer unit 12 and the processing chamber 13 constitute a vacuum container unit 10 . The sputtering apparatus 1 also includes a control unit, which controls the entire apparatus; a vacuum discharge system; a power supply unit and other components, although not shown in the figure, because they are not directly related to the present invention.

[0030] The transfer unit 11 transfers the wafer for thin film formation to the vacuum vessel unit 10 along an arrow A indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com