Package structure of surface adhesive light -emitting diode and its producing method

A technology for light-emitting diodes and packaging structures, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as inability to meet, and achieve the effect of reducing the thickness of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A light-emitting diode (Light-Emitting Diode; LED) acts like a small light bulb that emits light when current passes through it. In the switches of many electrical appliances, light-emitting diodes are used to represent whether the power is on or not. For example, a computer panel usually has a Turbo indicator light, a power indicator light, a hard disk access light, etc., all of which use light-emitting diodes as display components.

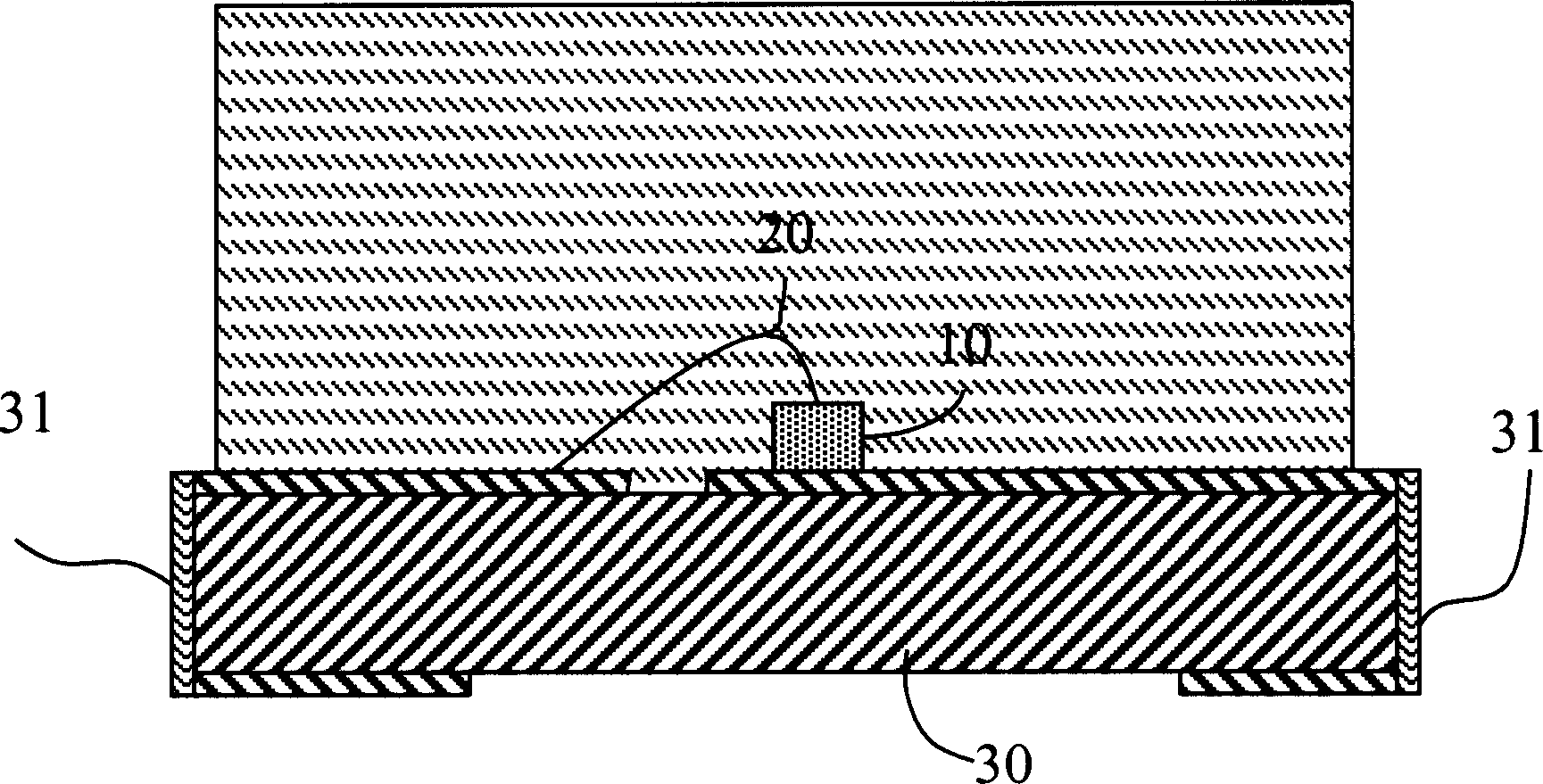

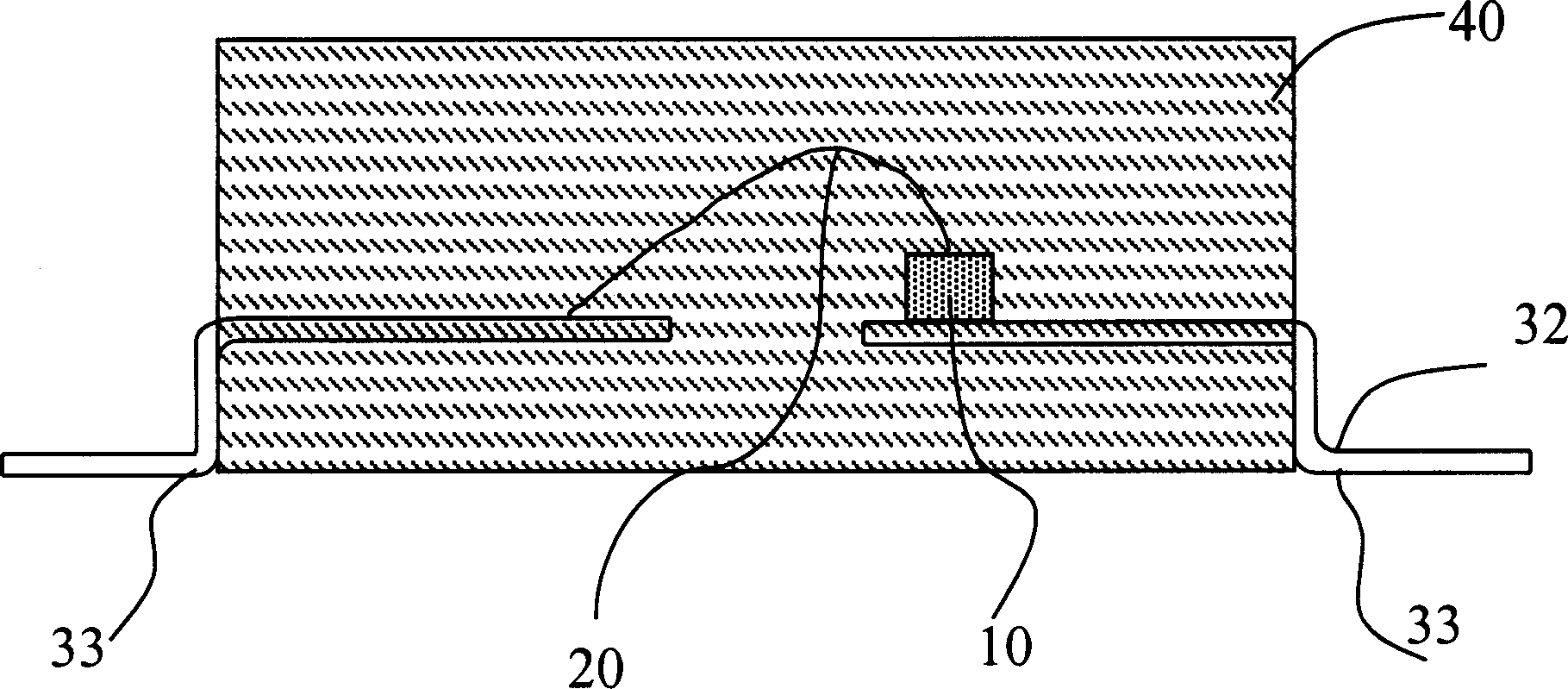

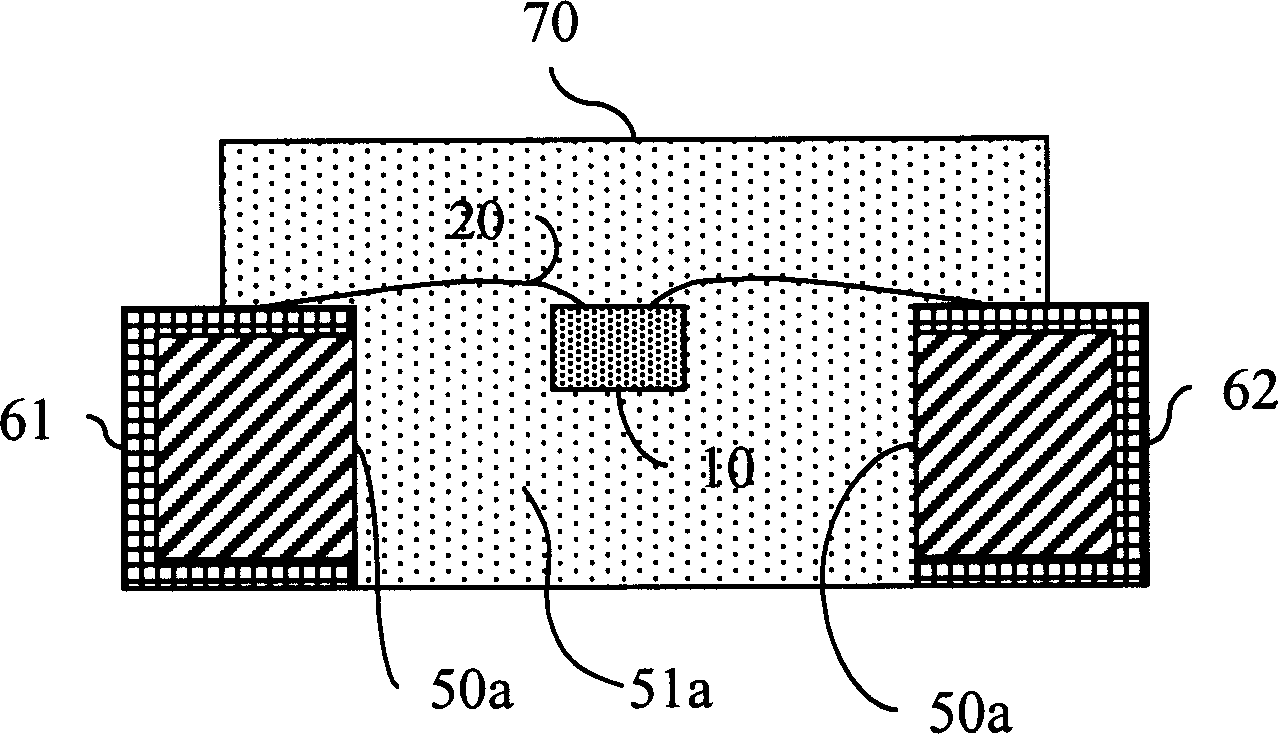

[0023] The light-emitting diode has the advantages of strong mechanical strength, long service life, high brightness, high electro-optical conversion efficiency, and low voltage function. It is used as an indicator light to gradually replace the status of the previous tungsten lamp; There are several types of light-emitting diodes in the practical stage, each with its own advantages and application occasions. One of the surface-mounted light-emitting diodes is a light-emitting diode that can be directly bonded to a predetermined position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com