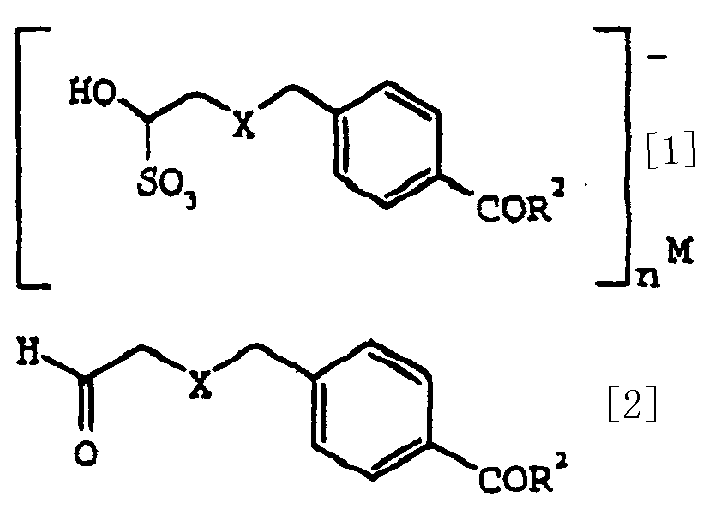

Method and intermdeiate used for manufacturing antifolic acid agent

A technology of solvents and compounds, applied in the field of synthetic organic chemistry, can solve problems such as difficult to obtain pure compounds of general formula XIV and difficult to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] plan 1

[0044] The mixture containing the compound of general formula III can be obtained by dissolving or suspending the compound of general formula II in a suitable solvent and adding the compound of general formula II in the presence of a suitable thermodynamic base and a phase transfer catalyst, optionally in the presence of a metal cation chloride. I compound and palladium catalyst. After all reactants are added together, the reaction proceeds at a temperature of at least about 0°-100°C. Within this broad temperature range, when Lg is a bromide in the compound of general formula II, the reaction mixture should be heated to at least about 50°C, preferably at least about 60°C, most preferably at least about 65°C, for about 8- 24 hours. When Lg is iodide, the reaction is enhanced, and about 0°-25°C is a typical temperature range, preferably room temperature. The reaction is preferably carried out for about 8-10 hours....

Embodiment 1

[0075] 4-(4-Methoxyphenyl)butyraldehyde

[0076] Deloxan used below THP Type 2 resin was pretreated by mixing with isopropanol (2.0 vol, 20 ml) and washing with ethyl acetate (4.0 vol, 40 ml). Filter the organic layer / resin slurry before subsequent use.

[0077] Methyl 4-bromobenzoate (60.0 g, 279.0 mmol), lithium acetate dihydrate (31.31 g, 306.9 mmol), lithium chloride (35.48 g, 837 mmol) and tetrabutylammonium chloride (41.22 g, 131.49 mmol) Add to dimethylformamide (698ml). The resulting solution was degassed by bubbling nitrogen. 3-Buten-1-ol (24.19g, 28.81ml, 334.81mmol) and palladium acetate (1.57g, 6.9gmmol) were added and the reaction mixture was heated and stirred at 65°C for about 10 hours. Completion of the reaction was indicated by HPLC monitoring of consumption of starting material (less than 0.4% methyl 4-bromobenzoate remaining) (reverse phase, 60% acetonitrile: 2.5% acetic acid buffer). The reaction mixture was cooled to 25°-30°C, water (700ml) and ethy...

Embodiment 2

[0079] 1-Hydroxy-4-(4-methoxyphenyl)butanesulfonic acid sodium salt

[0080] The ethyl acetate extract of Example 1 was concentrated in vacuo at about 37°C to 3.6 vol (8.7 ml). Alcohol 3A (3 vol, 7.2 ml) and water (0.63 vol, 1.51 ml) were added, followed by sodium bisulfite (1.04 g, 10.03 mmol). The reaction mixture was stirred for about 8 hours. After 10 minutes, the sulfonic acid started to crystallize. through 1 H NMR analysis of the filtrate of the reaction mixture verified the completion of the reaction. The resulting white slurry was filtered to afford the title compound (2.78 g, 8.98 mmol) as a white crystalline solid in about 80% yield. The filter cake was washed with ethanol (1.8 vol) and dried under vacuum at 40°C. Isomer impurities were not detected by NMR. 1 H-NMR: (d 6 -DMSO) δ7.86(d, J=8.27Hz, 2H), 7.32(d, J=8.27Hz, 2H), 5.33(d, J=2.3Hz, 1H), 3.84(m, 1H), 3.81( s, 3H), 2.63(m, 2H), 1.75(m, 1H), 1.73(m, 1H), 1.61(m, 1H), 1.48(m, 1H). 13 C-NMR: (d 6 -DMSO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com