Method of jointing plastics sheet materials

A technology of plastic materials and sheets, applied in thin material processing, manufacturing of rigid/semi-rigid containers, paper/cardboard containers, etc., can solve the problems of reduced flexibility, difficult expansion, loss of pulse energy, etc., and achieves less possibility of leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The best way to practice the invention

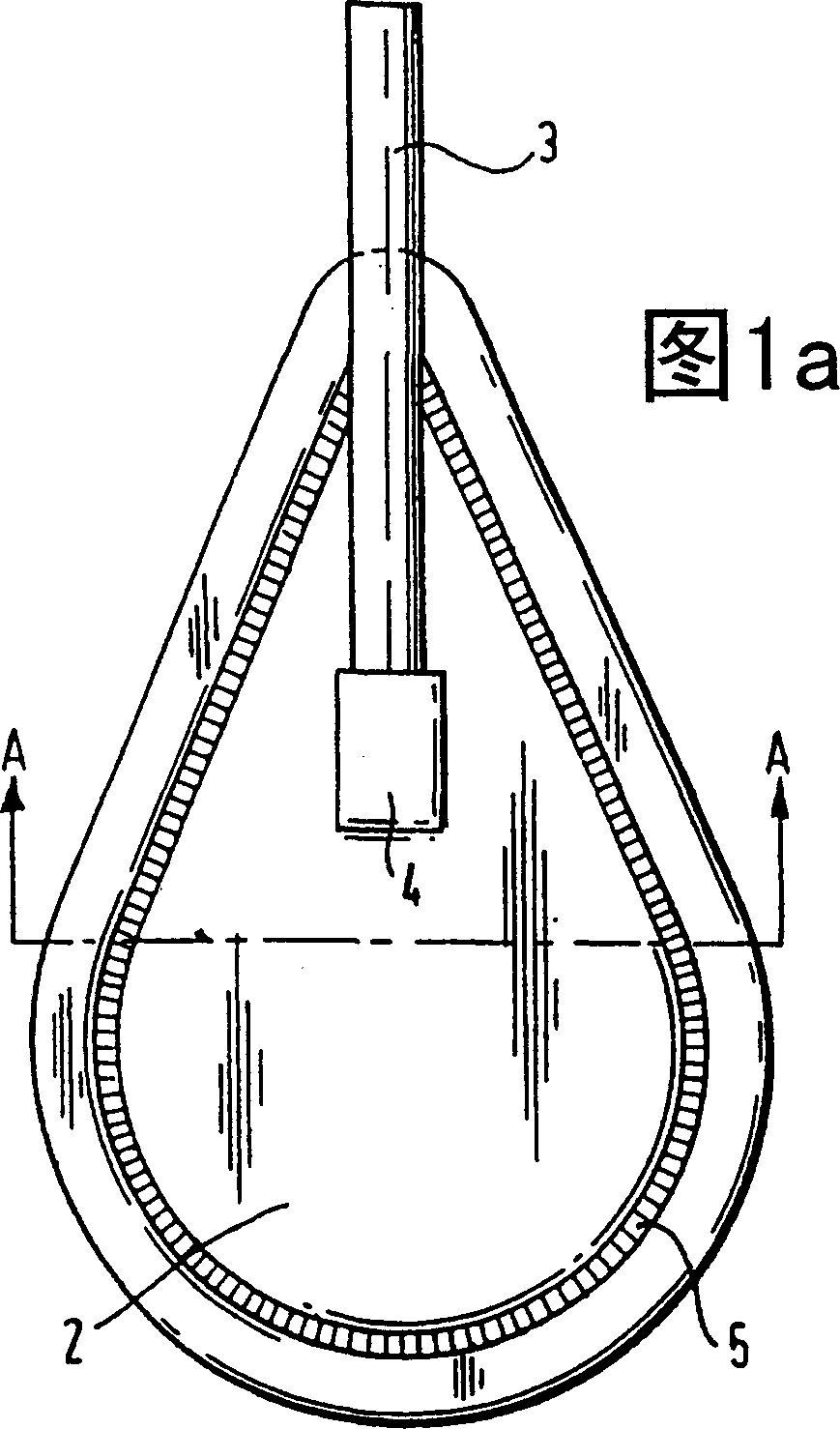

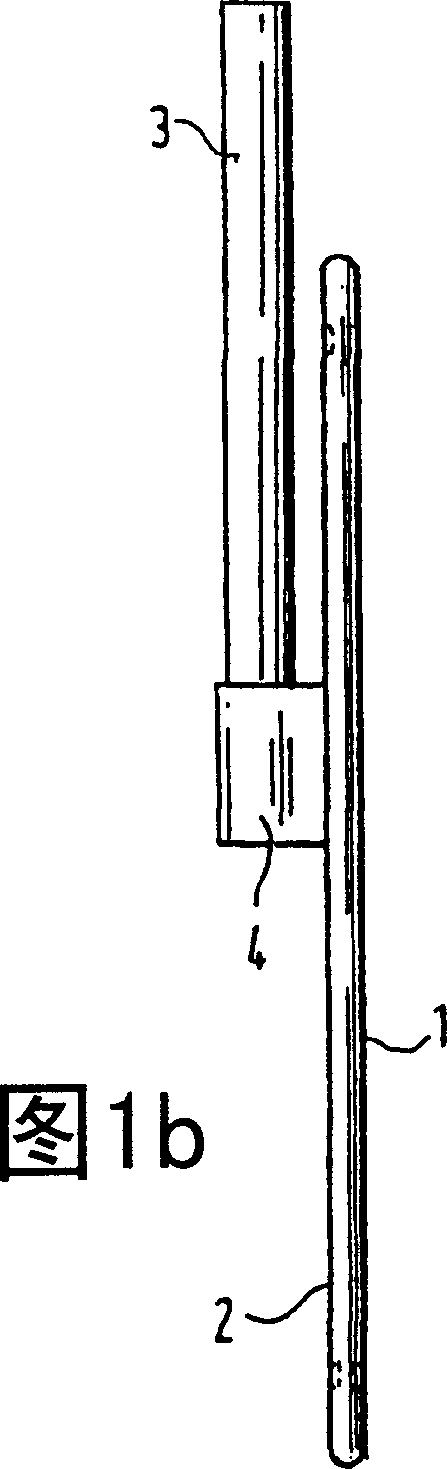

[0024] Referring to Figure 1, the figure shows the use of radio frequency welding to form the A-V Impulse System TM Common method of inflatable bladder.

[0025] The bladder shown in Figure 1 comprises two oval flexible plastic sheets 1 and 2 welded together by radio frequency welding along their overlapping outer edge portions. The bladder has an inlet duct 3 for pressurized air which is connected to a molded inlet boss 4 formed on the skin 2 .

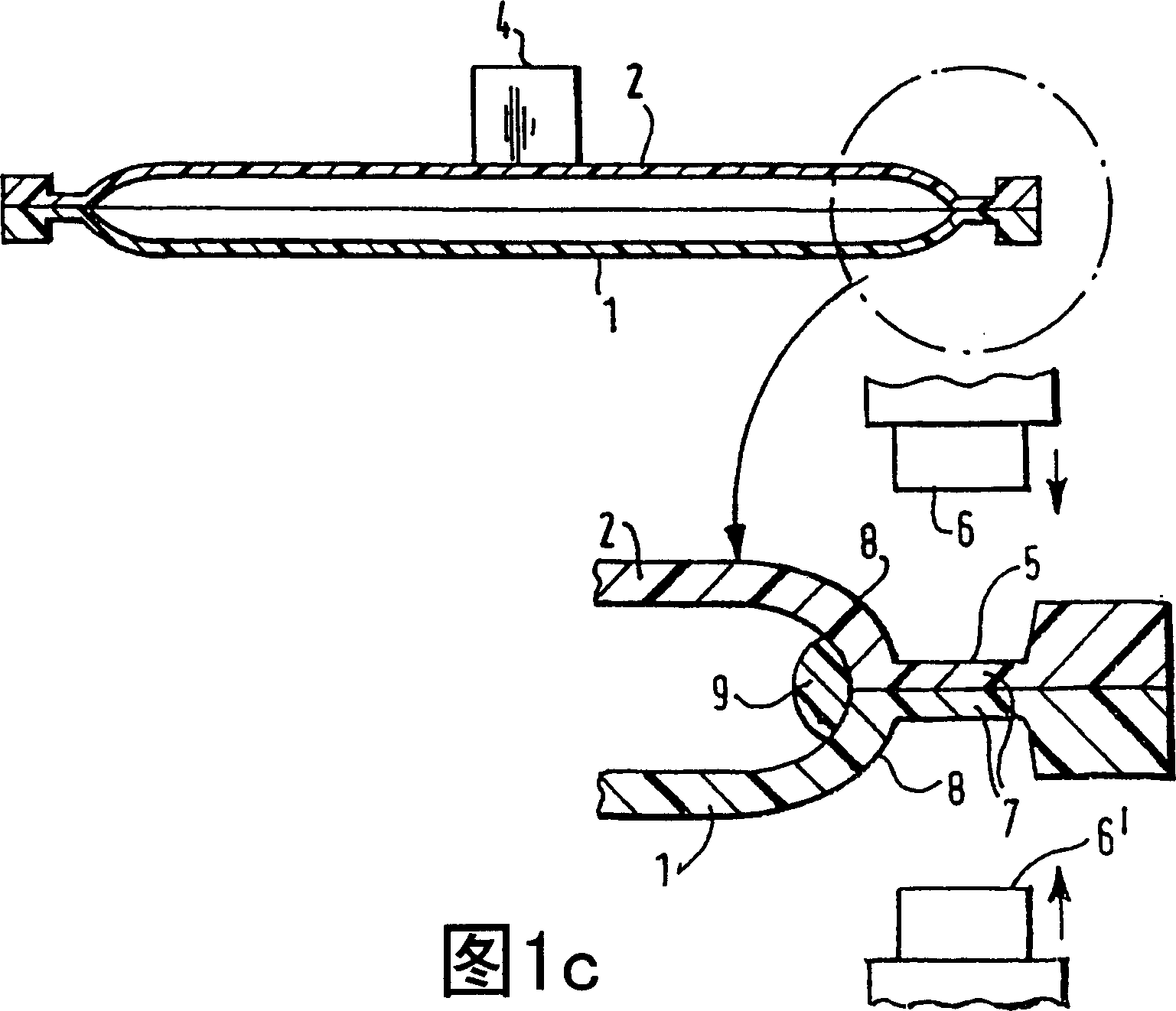

[0026] The thickness of the capsule skin used in this example was 0.25 mm. The edge portions of bladders 1 and 2 are held in overlapping relationship as shown, and radiofrequency welding is applied in region 5 at a distance from the peripheral edges of skins 1 and 2 by bringing electrodes 6, 6' closer together so that at 7 Form a cross-section of reduced thickness, typically 50%-70% of the original thickness.

[0027] The result of the weld is that at 8 of the two materials, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com