Electric hydraulic disassembling and assembling machine of coupling buffer device for rolling stock

A technology for railway locomotives and buffer devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in disassembling and assembling a coupler buffer device in station repairs, and achieve the effects of improving operating means, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

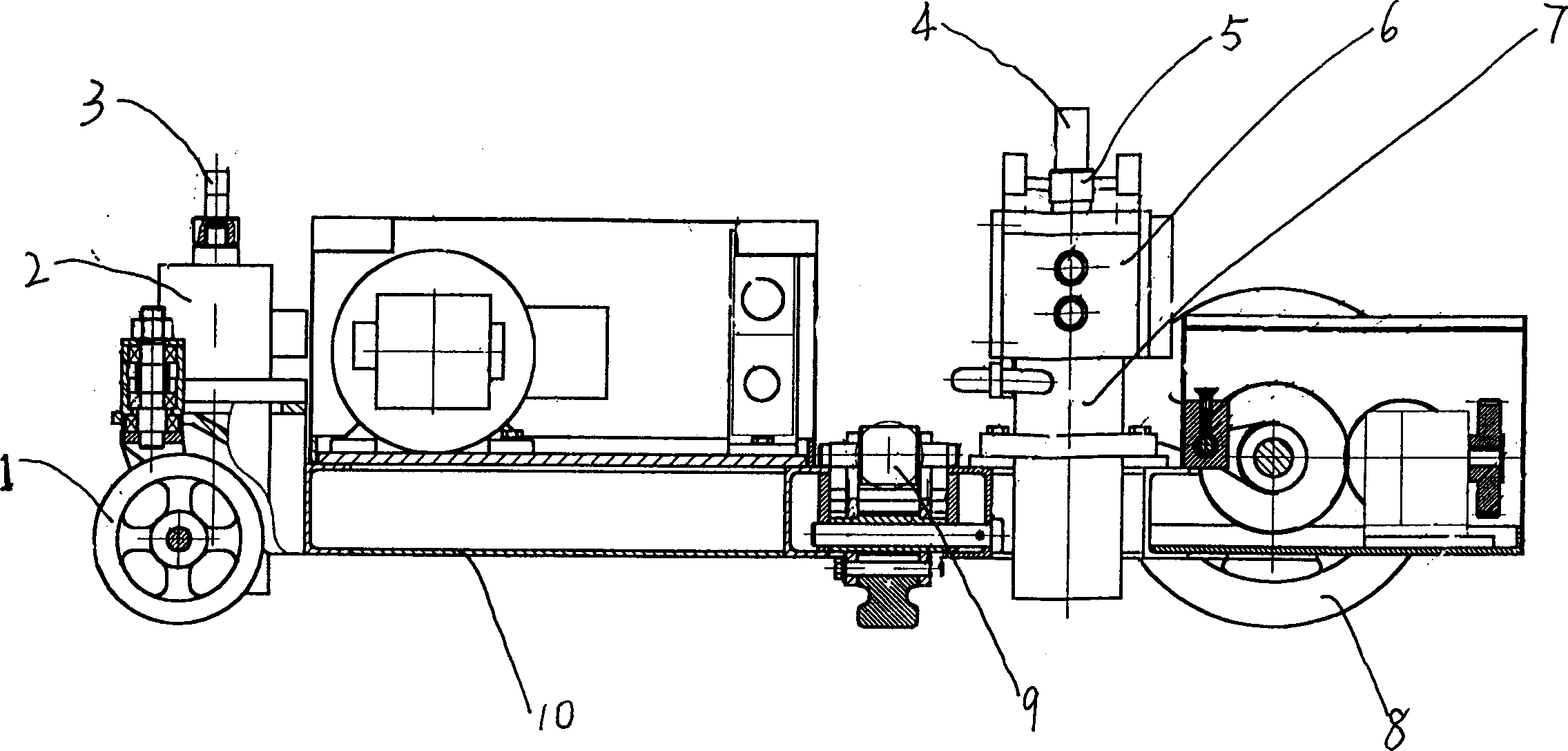

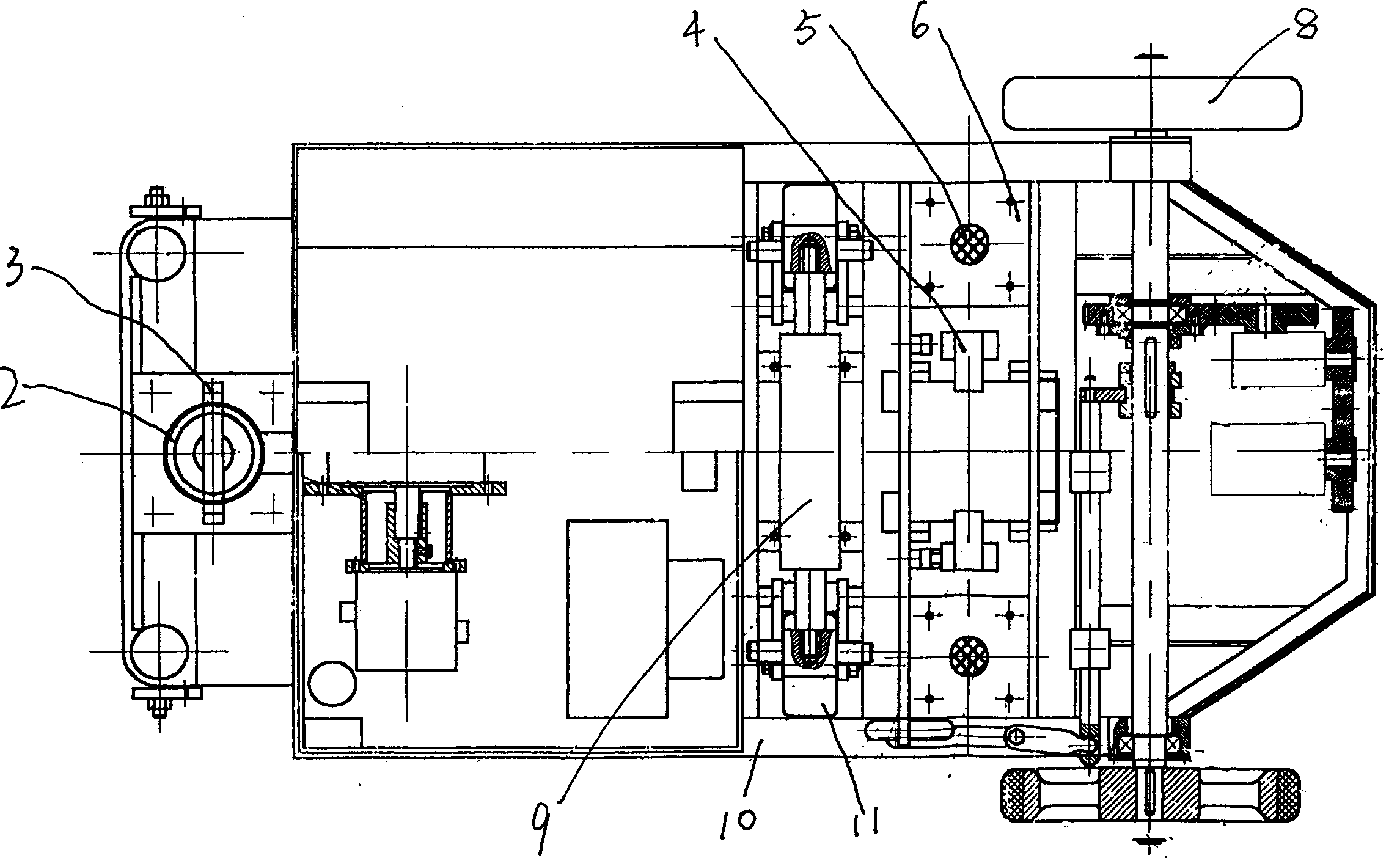

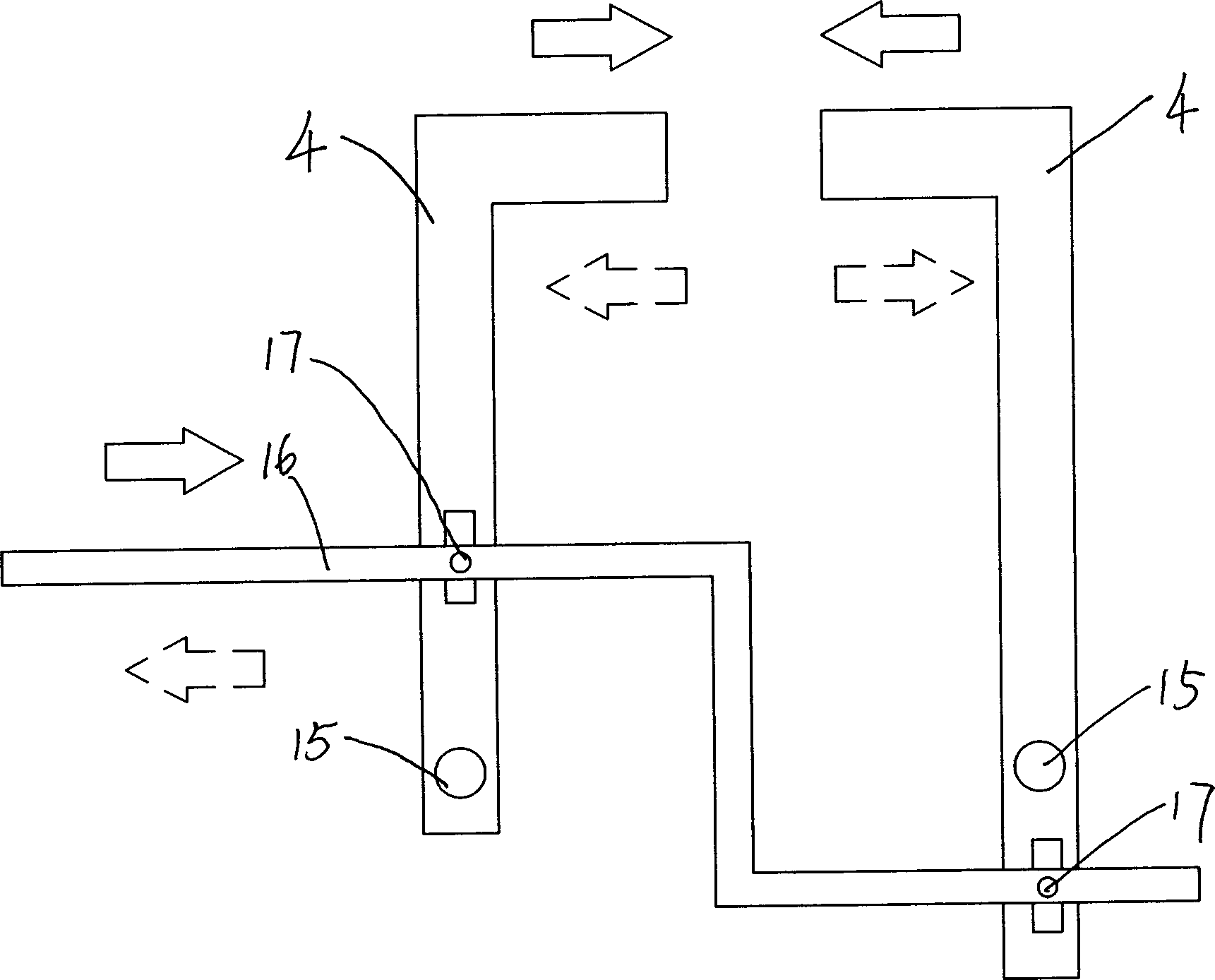

[0015] Such as figure 1 , figure 2 As shown, the electro-hydraulic dismounting machine for the coupler buffer device of the railway locomotive is composed of a driving frame 10, a hydraulic dismounting mechanism assembled at the front of the driving frame 10, and a hydraulic pressure-bearing mechanism assembled at the rear, and the rear of the driving frame 10 The front part is equipped with two universal wheels 1, and the front part is equipped with two directional wheels 8 in the front and rear directions. The front part of the car is equipped with a frame lifting mechanism. The directional wheel 11 of left and right directions, two piston rods of vehicle frame lifting oil cylinder 9 are hinged with lifting rotating support. The hydraulic cylinder of the above-mentioned hydraulic pressure-bearing mechanism adopts a double-stage double-acting telescopic cylinder 2, and the top of the piston rod of the cylinder 2 is equipped with a pressure-bearing support 3. The assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com