Gronnd surface electric measuing method for detecting underground metal pipeline corrusion state

A metal pipeline and electrical measurement technology, applied in the fields of corrosion detection, non-destructive testing, and underground pipeline survey, can solve the problems of difficulty in detection and other problems, and achieve the effects of low detection cost, simple working method and low equipment price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

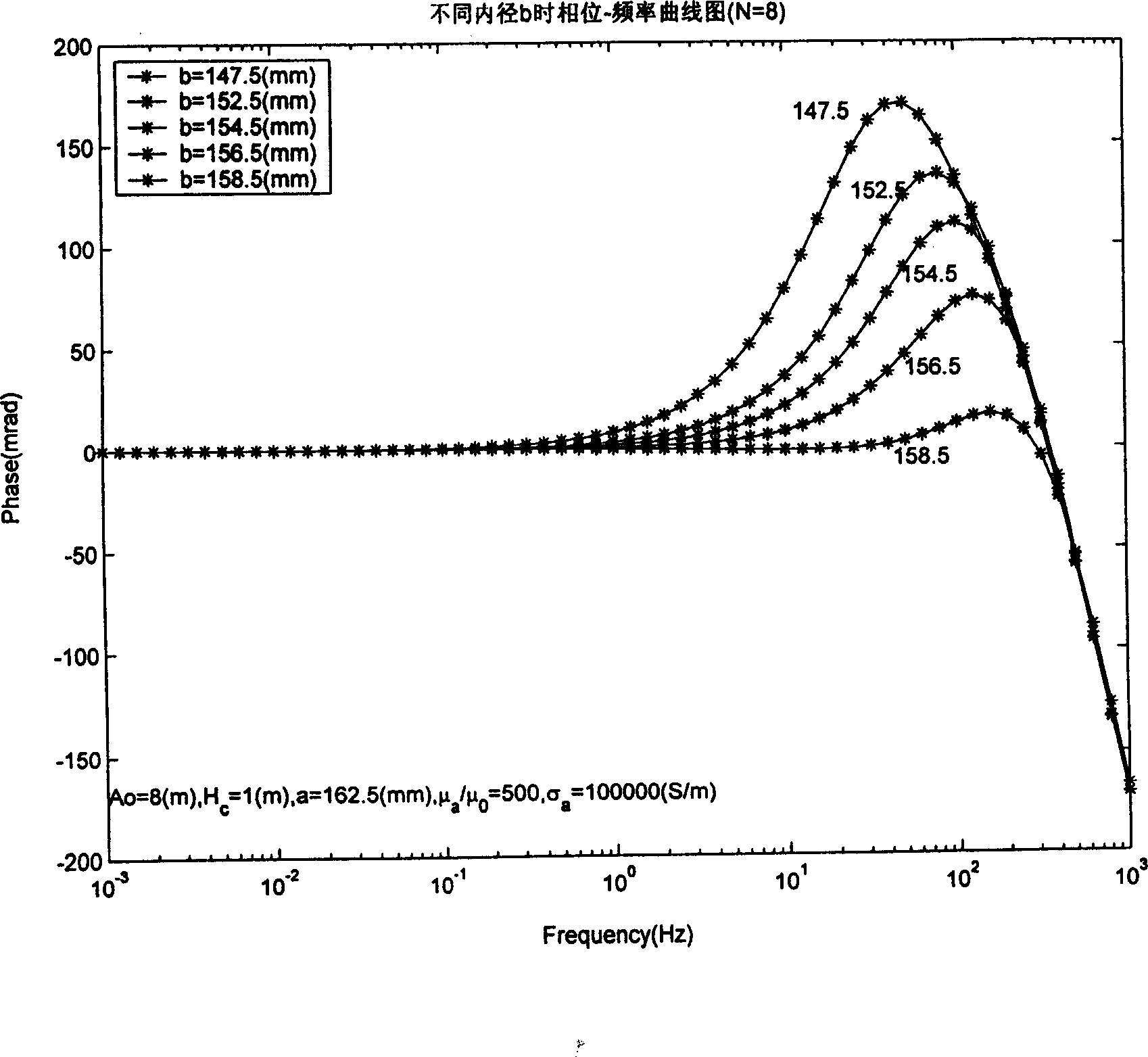

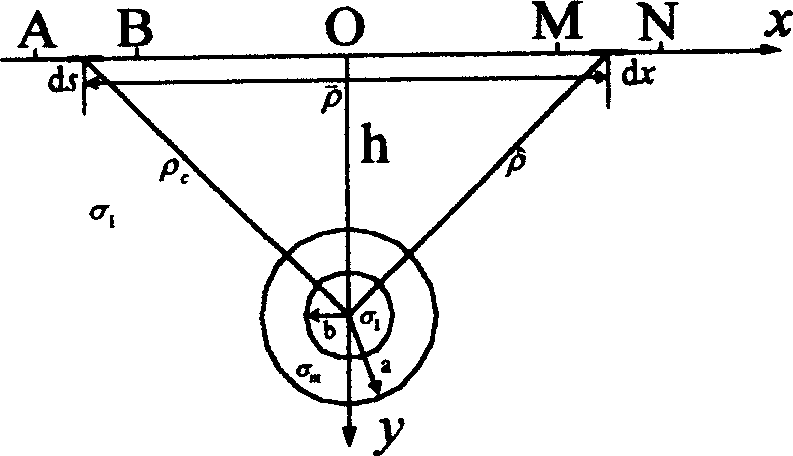

[0020] In order to study the feasibility of surface broad-spectrum electrical measurement to detect the corrosion condition of underground metal pipelines, we in Wait and Williams [2] On the basis of the deduced theoretical formula, the theoretical formula of the amplitude and phase of the alternating electric field measured by the electrode device arranged on the ground vertical to the direction of the pipeline is deduced when there is an infinitely long metal pipeline installed horizontally underground. [2] Wait, J R and Williams J T. EM and IP response of a steel well casing for a four-electrode surface array. Part I: Theory, Geophysical Prospecting, 1985, 33: 723-735. On this basis, the theoretical spectrum curves of underground metal pipelines with the same outer diameter and different wall thicknesses are calculated when the electrode device is measured.

[0021] The spatial position, coordinates and geophysical parameters of the section of the metal pipeline during cal...

Embodiment 2

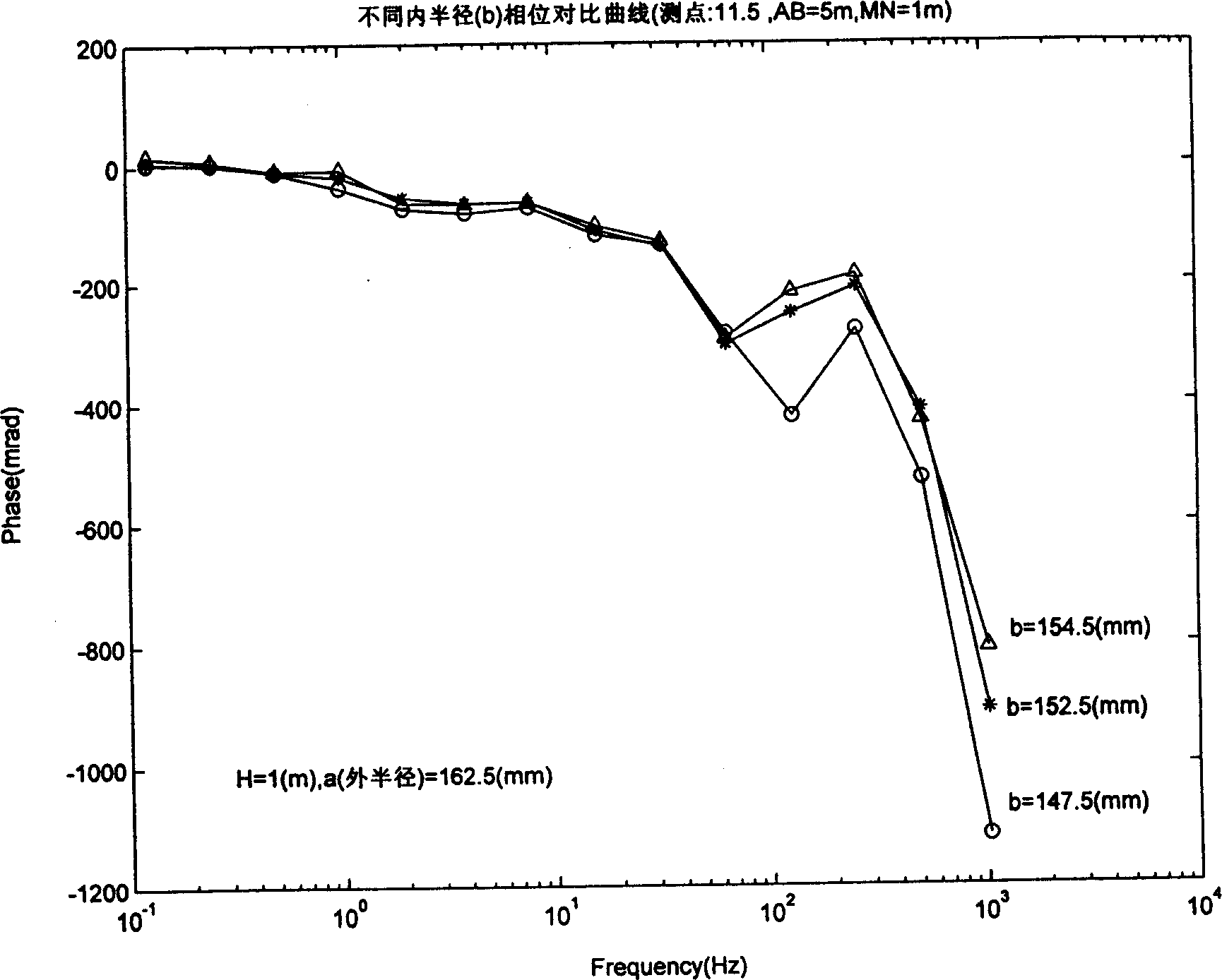

[0025] Because in practice, in order to prevent the outer surface of underground steel oil and gas pipelines from being corroded, the outside is covered with a high-resistance anti-corrosion layer. For such underground metal pipelines, the above-mentioned method of theoretical calculation and inversion to understand the corrosion status is not applicable. of. To this end, we wrapped three 20-gauge steel seamless steel pipes with a length of 10.3m, an outer diameter of 325mm, and wall thicknesses of 15mm, 10mm, and 8mm, and then buried them in three different locations underground (so that they would not Interaction), constructed three physical models, the central buried depth is 1m. On the measuring line arranged vertically through the center of the steel pipe, the power supply electrode AB is located on the left of point O, AB=5m, BO=5m; the measuring electrode is located on the right of point O, OM=1m, MN=1m, used for mineral exploration Measurements were carried out using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com