Beating extractor

A technology of extraction device and barrel, which is applied in solid solvent extraction and other directions, can solve the problems of low production efficiency, unsuitable crushing of lightweight materials, wet crushing, etc., and achieves the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

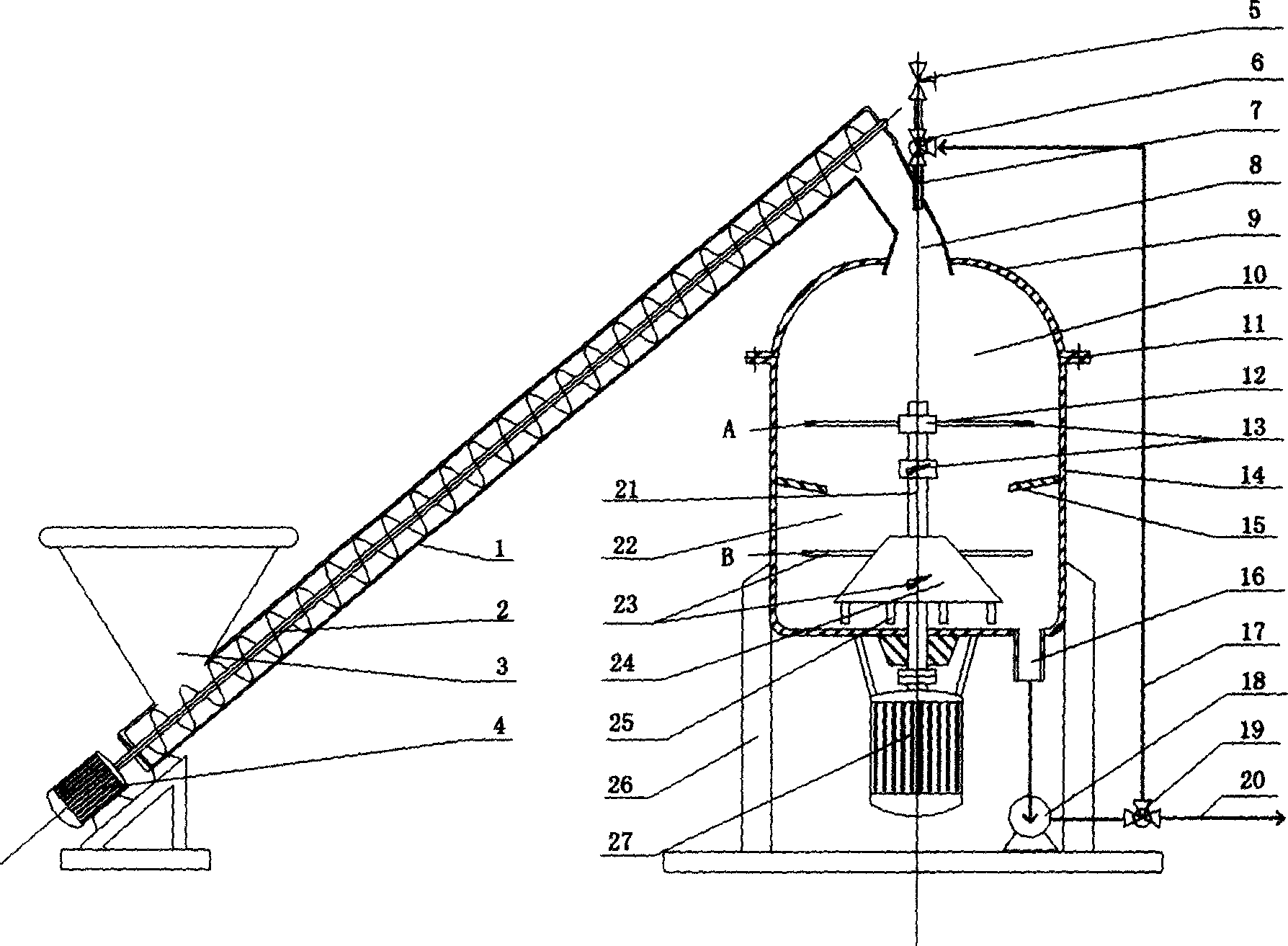

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

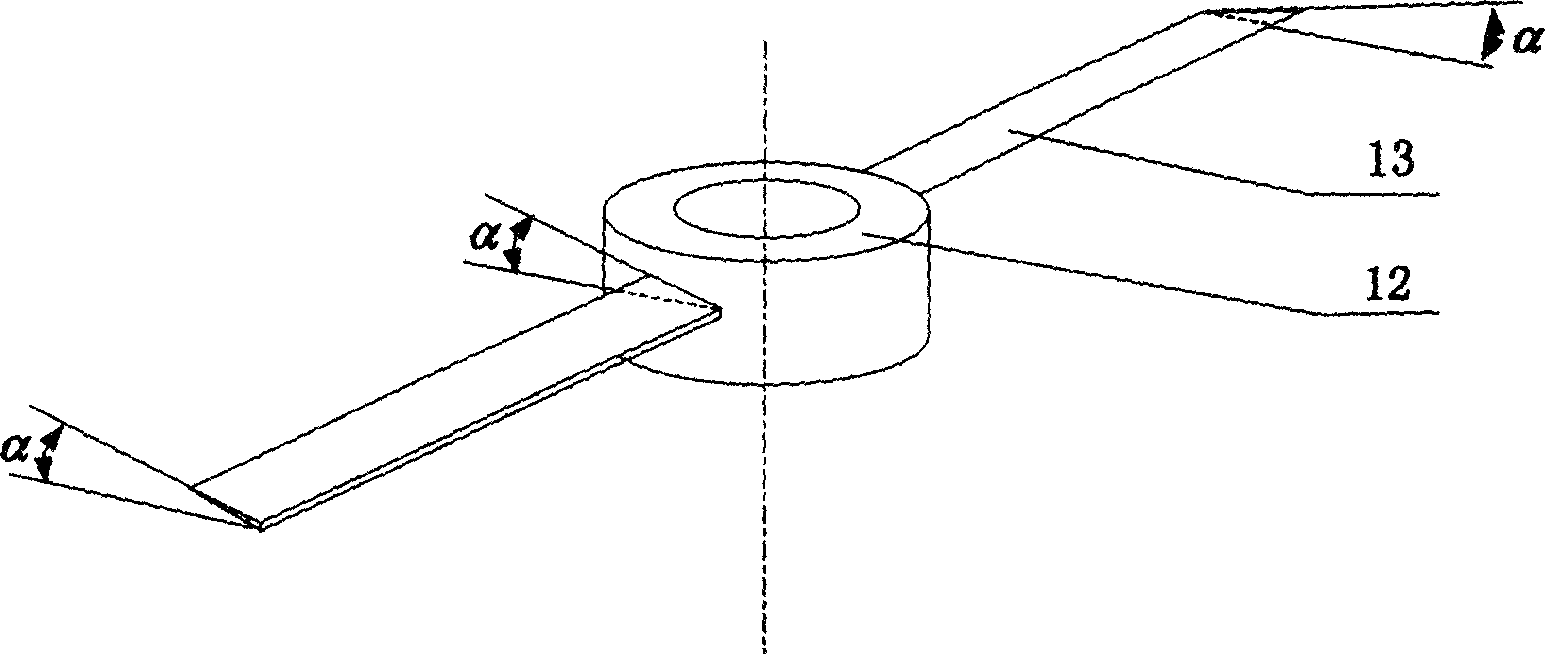

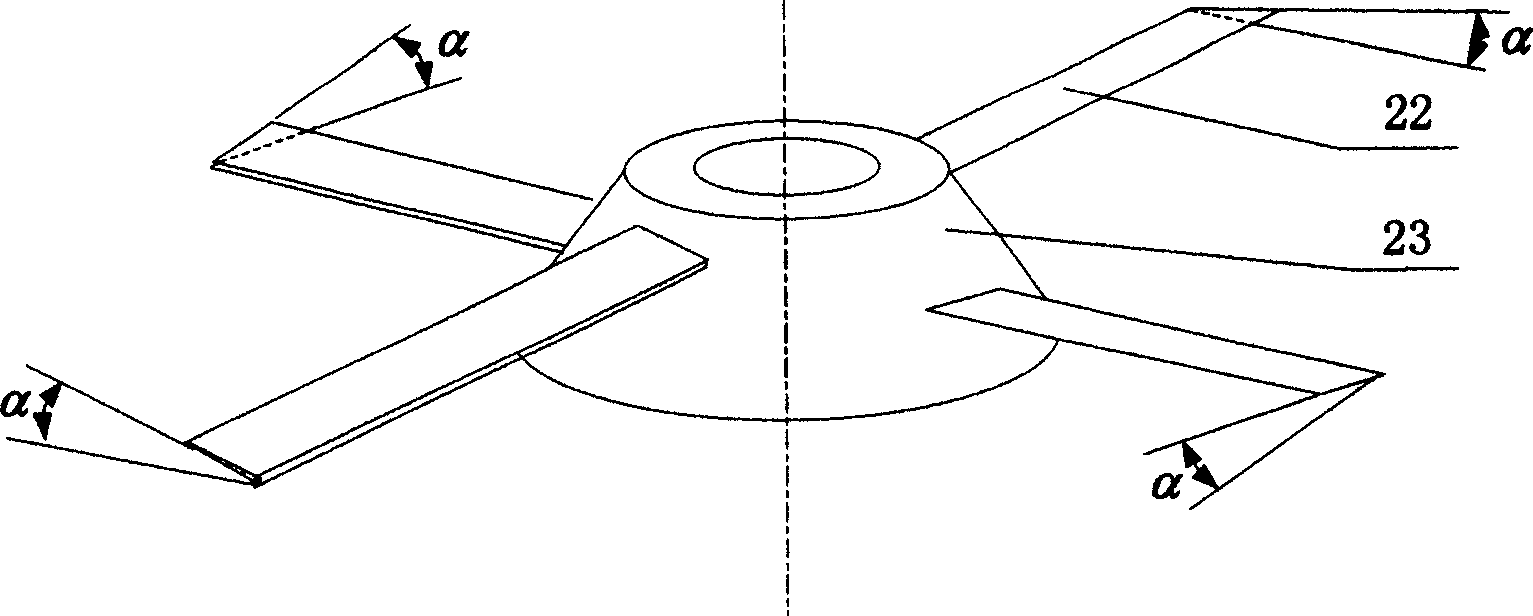

[0018] Depend on figure 1 -- Figure 4 It can be seen that the housing formed by connecting the machine cover 9 and the housing 14 is equipped with a guide baffle 15, which divides the housing 14 into two spaces, the upper space is the chopping chamber 10, and the lower space is the beating chamber 22. The bottom of the shell 14 is equipped with a concentric cutter shaft 21 connected to the motor 27. The cutter shaft 21 in the chopping chamber 10 is equipped with mutually perpendicular chopping knives 13. The cutter shaft in the beating chamber 22 is equipped with a conical cutter head. 24. A beating flat knife 23 is installed on the conical surface of the cutter head 24, a symmetrical beating vertical knife 25 is installed at the bottom of the cutter head 24, the lower part of the shell is fixed on the machine base 26, and an end The screw propu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com