A kind of graphene-based antioxidant and its preparation method and application

A graphene-based, antioxidant technology, applied in the production of bulk chemicals, etc., can solve the problems of no anti-aging, long reaction cycle, lack of comparative experiments, etc., achieve high initial degradation temperature, improve thermal oxygen stability, Increase the effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

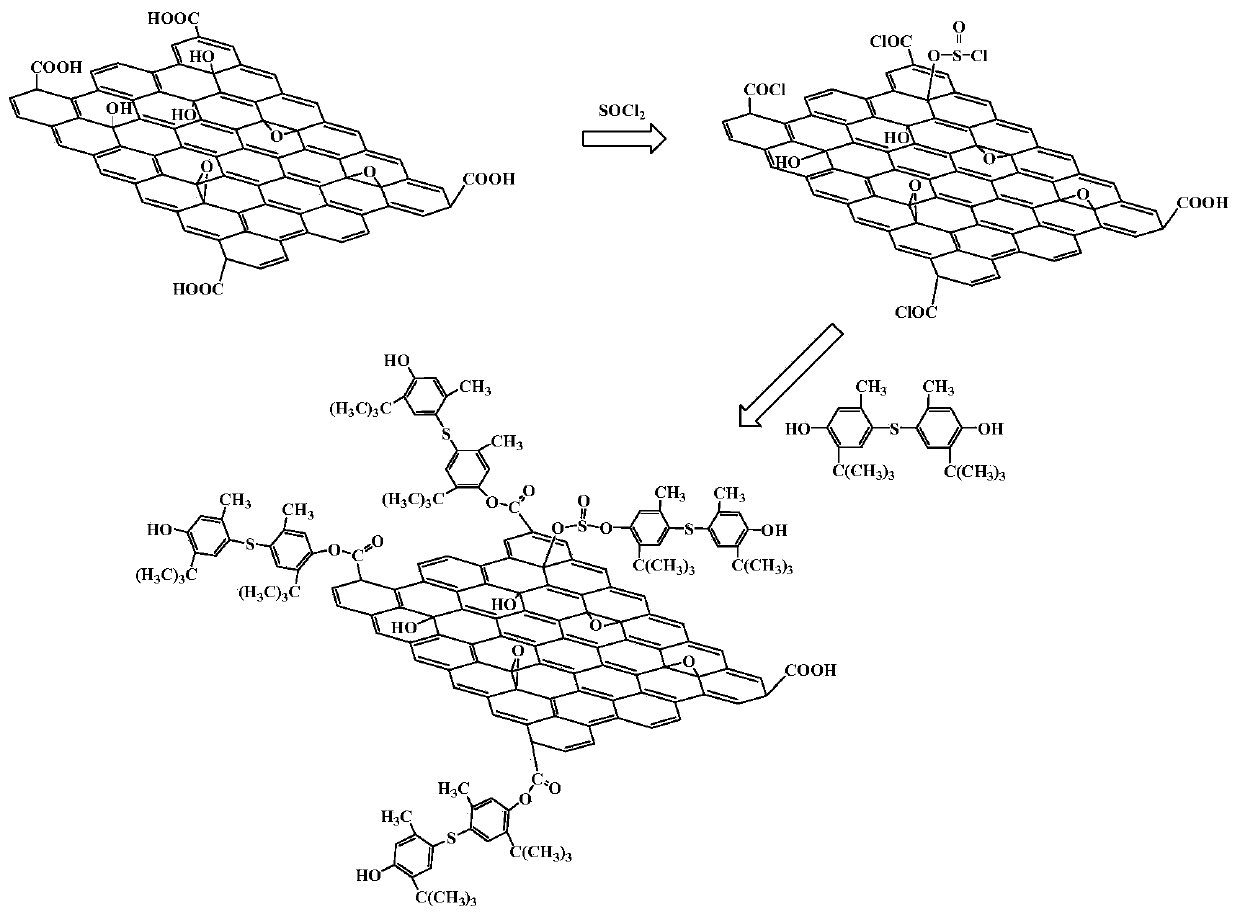

[0059] Prepare graphene-based antioxidant, the specific preparation process is as follows figure 1 shown, prepared by the following steps:

[0060] A, preparation of graphite oxide: prepare graphite oxide according to the method reported in the document "DC, M., et al., Acs Nano, 2010.4 (8): p.4806";

[0061] B. Activation of carboxyl groups: disperse graphite oxide ultrasonically (probe ultrasonic in ice-water bath) in N,N-dimethylformamide, then add thionyl chloride for reaction to obtain graphene oxide with activated carboxyl groups; ultrasonic The dispersion power is 500W; the ultrasonic dispersion time is 30min; the solid-liquid ratio of graphite oxide to N,N-dimethylformamide is 0.65:1 (mg / ml); the solid-liquid ratio of graphene oxide to thionyl chloride ( g / ml) was 1:100; the reaction was specifically stirred at 70°C for 24h under an argon atmosphere;

[0062] C, remove excess reactant: adopt underpressure distillation to remove remaining thionyl chloride in the react...

Embodiment 2

[0072] Prepare graphene-based antioxidant, the specific preparation process is as follows figure 1 shown, prepared by the following steps:

[0073] A, preparation of graphite oxide: prepare graphite oxide according to the method reported in the document "DC, M., et al., Acs Nano, 2010.4 (8): p.4806";

[0074] B. Activation of carboxyl groups: disperse graphite oxide ultrasonically (probe ultrasonic in ice-water bath) in toluene, then add thionyl chloride to react to obtain graphene oxide with activated carboxyl groups; ultrasonic dispersion power is 600W; ultrasonic dispersion time For 20min; the solid-to-liquid ratio of graphite oxide and toluene is 0.38:1 (mg / ml); the solid-to-liquid ratio (g / ml) of graphene oxide and thionyl chloride is 1:100; Described reaction is specifically adopted in nitrogen gas Stir at 70°C for 24h under atmosphere;

[0075] C, remove excess reactant: adopt underpressure distillation to remove remaining thionyl chloride in the reaction;

[0076]D,...

Embodiment 3

[0085] Prepare graphene-based antioxidant, the specific preparation process is as follows figure 1 shown, prepared by the following steps:

[0086] A, preparation of graphite oxide: prepare graphite oxide according to the method reported in the document "DC, M., et al., Acs Nano, 2010.4 (8): p.4806";

[0087] B. Activation of carboxyl groups: disperse graphite oxide ultrasonically (probe ultrasonic in ice-water bath) in N,N-dimethylformamide, then add thionyl chloride for reaction to obtain graphene oxide with activated carboxyl groups; ultrasonic The dispersion power is 500W; the ultrasonic dispersion time is 30min; the solid-liquid ratio of graphite oxide to N,N-dimethylformamide is 0.5:1 (mg / ml); the solid-liquid ratio of graphene oxide to thionyl chloride ( g / ml) was 1:100; the reaction was specifically stirred at 70°C for 24h under an argon atmosphere;

[0088] C, remove excess reactant: adopt underpressure distillation to remove remaining thionyl chloride in the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com