Multi-linkage reciprocating extrusion type trace extraction-separation integrated device and using method

An extraction and micro-volume technology, which is applied in the field of multi-reciprocating extrusion-type micro-extraction-separation integrated devices, can solve the problems that samples cannot be extracted and have complex structures, so as to avoid material loss and cross-contamination, easy to operate, and improve The effect of test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

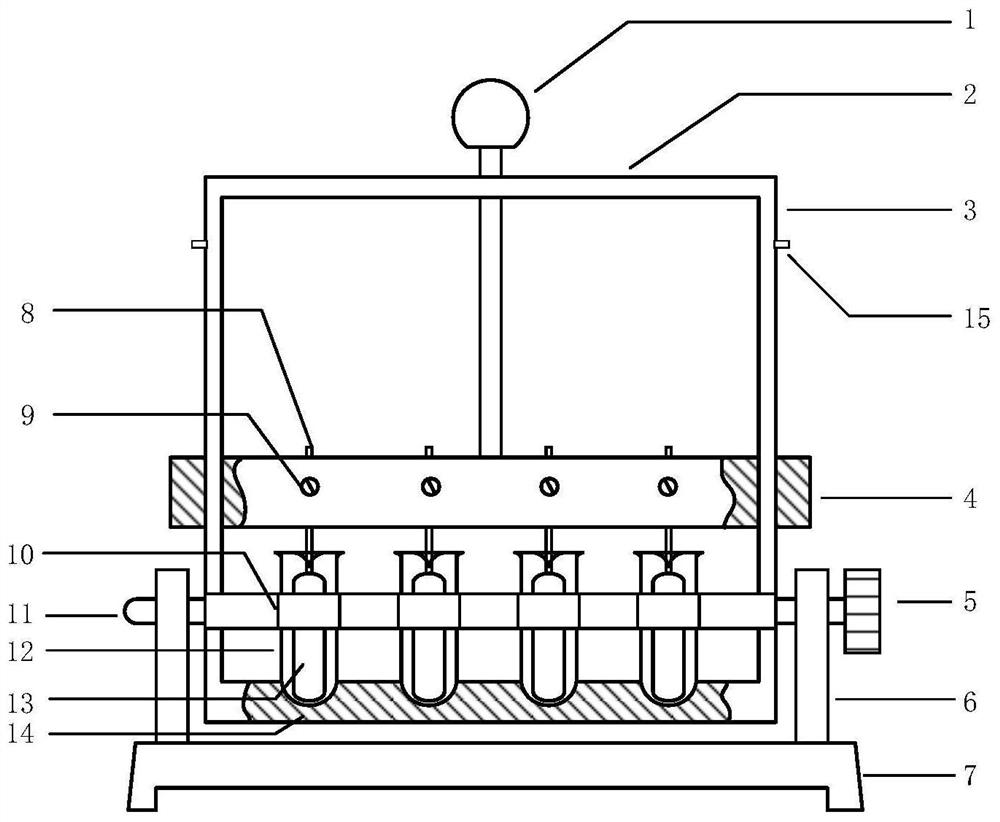

[0048] refer to figure 1 , the present embodiment provides a multi-connected reciprocating extrusion type micro-extraction-separation integrated device, including a tube rack assembly, a lifting assembly rotating shaft 11 and a bracket 6,

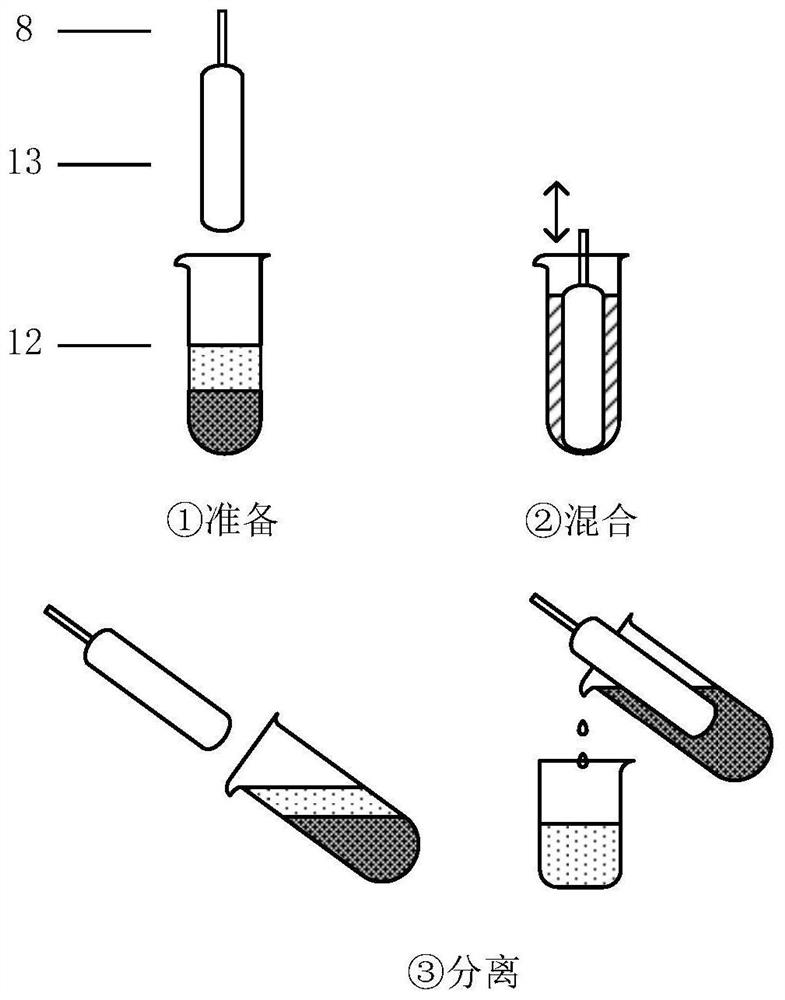

[0049] The tube frame assembly includes side guide rods 3 on both sides and a tube frame 10 connected between the two side guide rods 3, the tube frame 10 is provided with an extraction tube 12, and the extraction tube 12 is used for The place where the extraction and separation are carried out,

[0050] The pulling assembly includes a slider 4 connected between two side guide rods 3, the slider 4 is connected with a stirring and extruding column 13, and the slider 4 can slide up and down along the side guide rods 3, to drive the stirring and squeezing column 13 into and out of the extraction tube 12,

[0051] The outer side of the side guide rod 3 is connected to the bracket 6 through the rotating shaft 11, and the pipe frame assembly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com