Method for preprocessing black powder and its analogues

An analogue, black powder technology, applied in the field of spectral detection pre-processing, to achieve good processing effect and easy rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

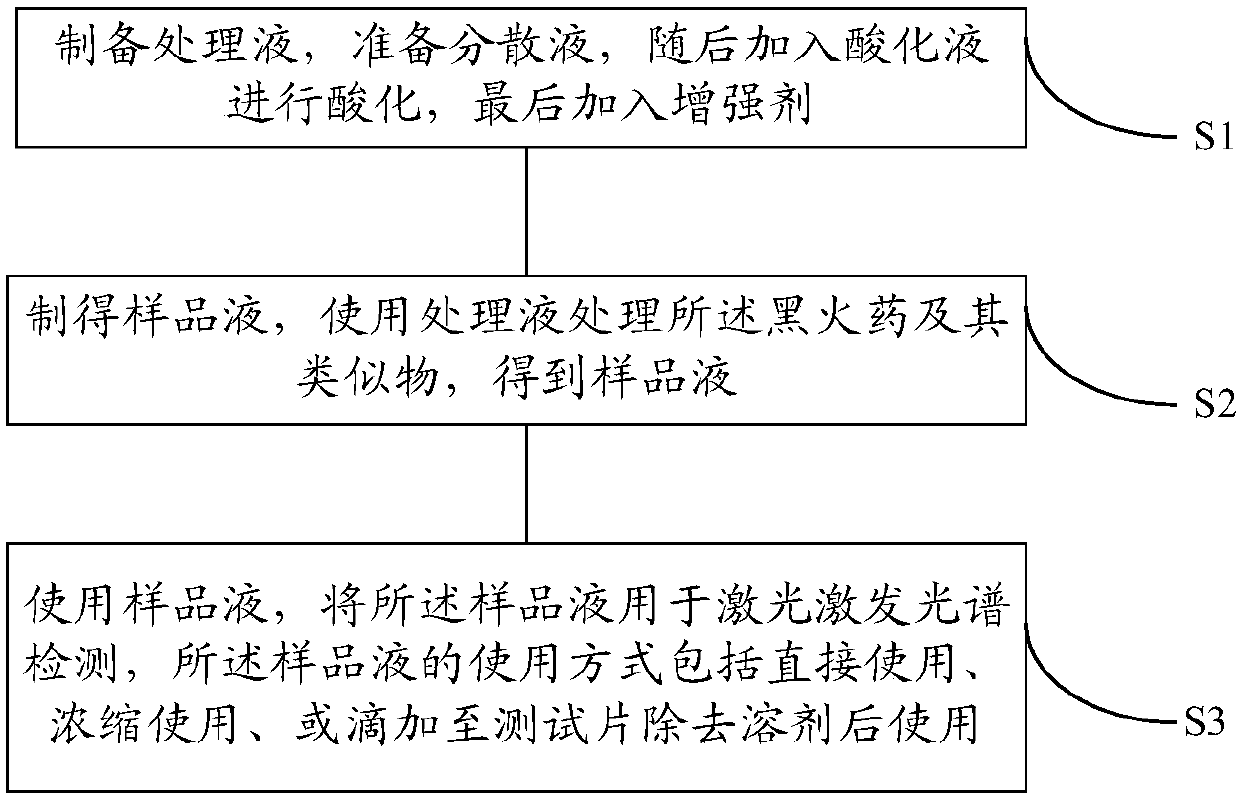

Method used

Image

Examples

Embodiment 1

[0067] Use the treatment solution to treat the black powder of experimental group 1, the treatment solution is 20g of aqueous solution, add the black powder into the beaker containing the treatment solution, heat and stir at 50°C for 2min, after fully dissolving, filter while hot to remove the precipitate, and get Sample solution 1 is set aside.

Embodiment 2

[0069] Prepare the treatment liquid, add 1 g of hydrochloric acid solution with a concentration of 2% to the dispersion liquid 19 g of water, acidify the dispersion liquid, and finally add 0.002 g of crown ether 18-crown-6; use the prepared treatment liquid treatment number as experimental group 2 Add the black powder into the beaker filled with the treatment liquid, stir and shake for 5 minutes, fully dissolve, remove the precipitate after centrifugation, and obtain sample solution 2 for later use.

Embodiment 3~8

[0071] Examples 3-8 Refer to the preparation process of Examples 1 and 2 to prepare corresponding sample solutions 1-8 for future use. Among them, during the mixing process of the treatment liquid and the black powder, one or more methods of stirring, shaking, ultrasonication, and heating can be selected, and the process of slag removal can be selected by filtration or centrifugation, and those skilled in the art can choose to use it according to the actual situation. . Generally, sonication and heating can accelerate the dissolution.

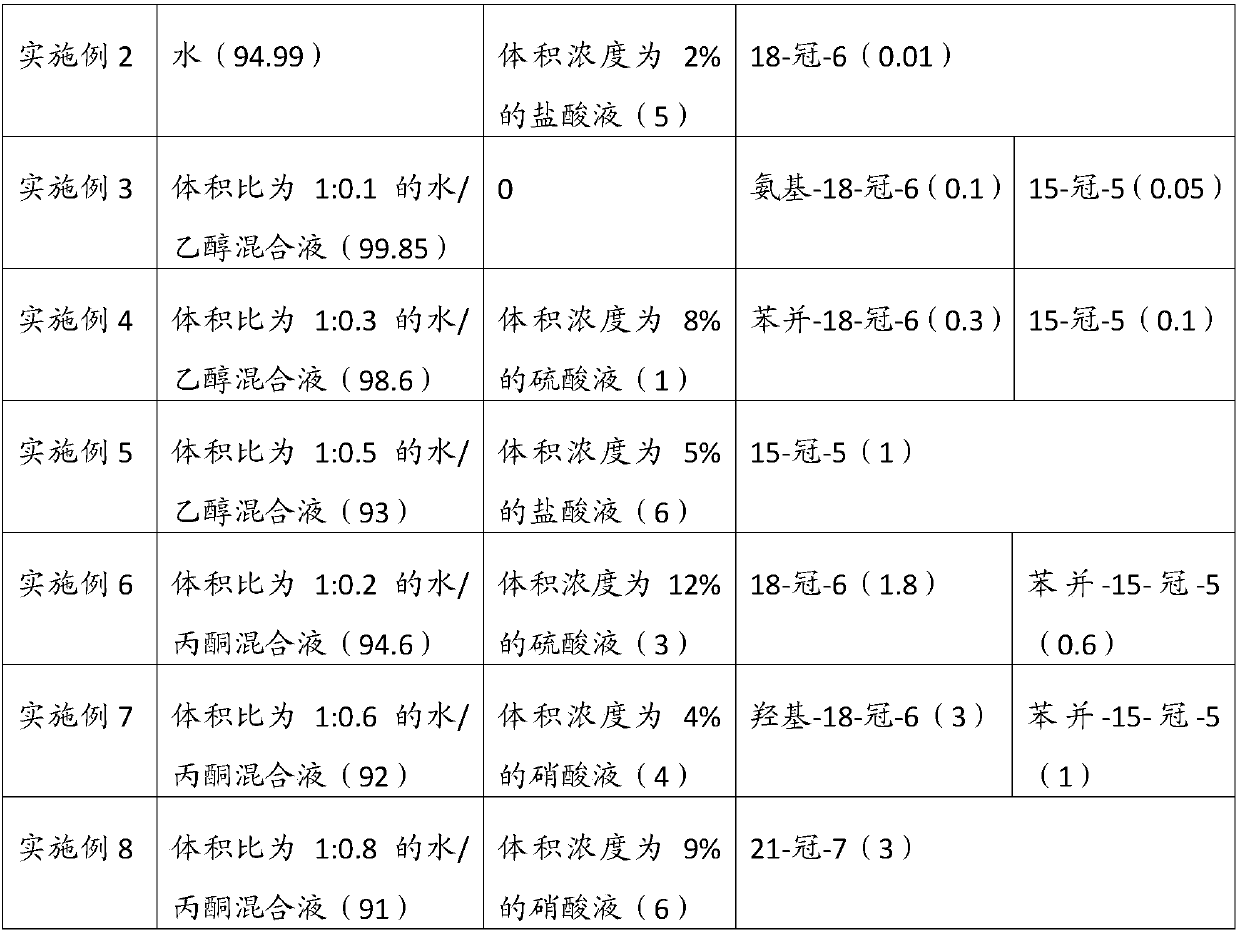

[0072] The treatment liquid quality that embodiment 1~8 uses is 20g, but the component of each treatment liquid and content change to some extent, and concrete embodiment situation is as shown in table 1:

[0073] Treatment liquid components and content list thereof in different embodiments of table 1

[0074]

[0075]

[0076] It should be noted that the values in the brackets in Table 1 are the corresponding mass percentages of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com