Vorticity compression pump

A technology of turbo compressor and compression mechanism, applied in the field of turbo compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

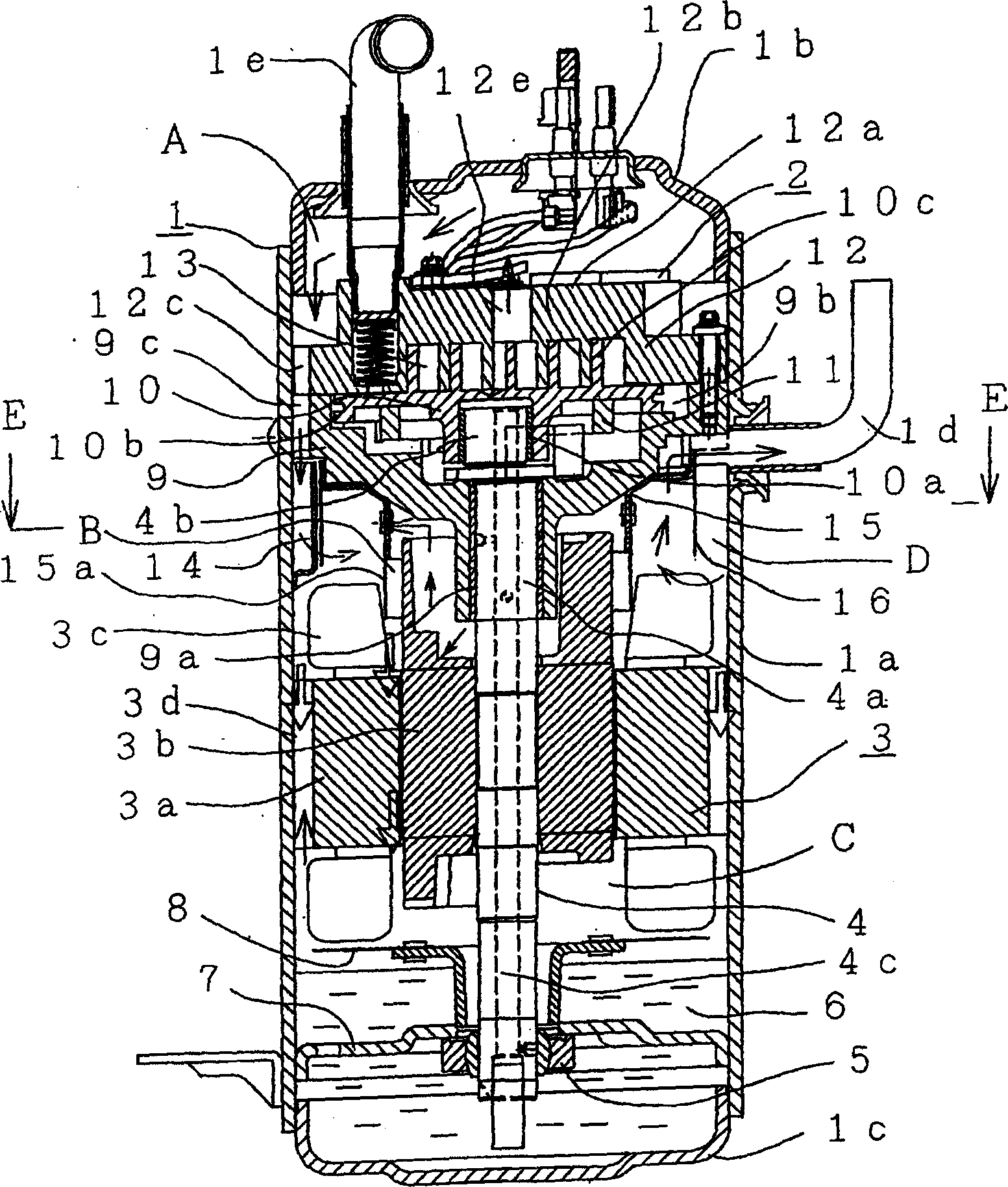

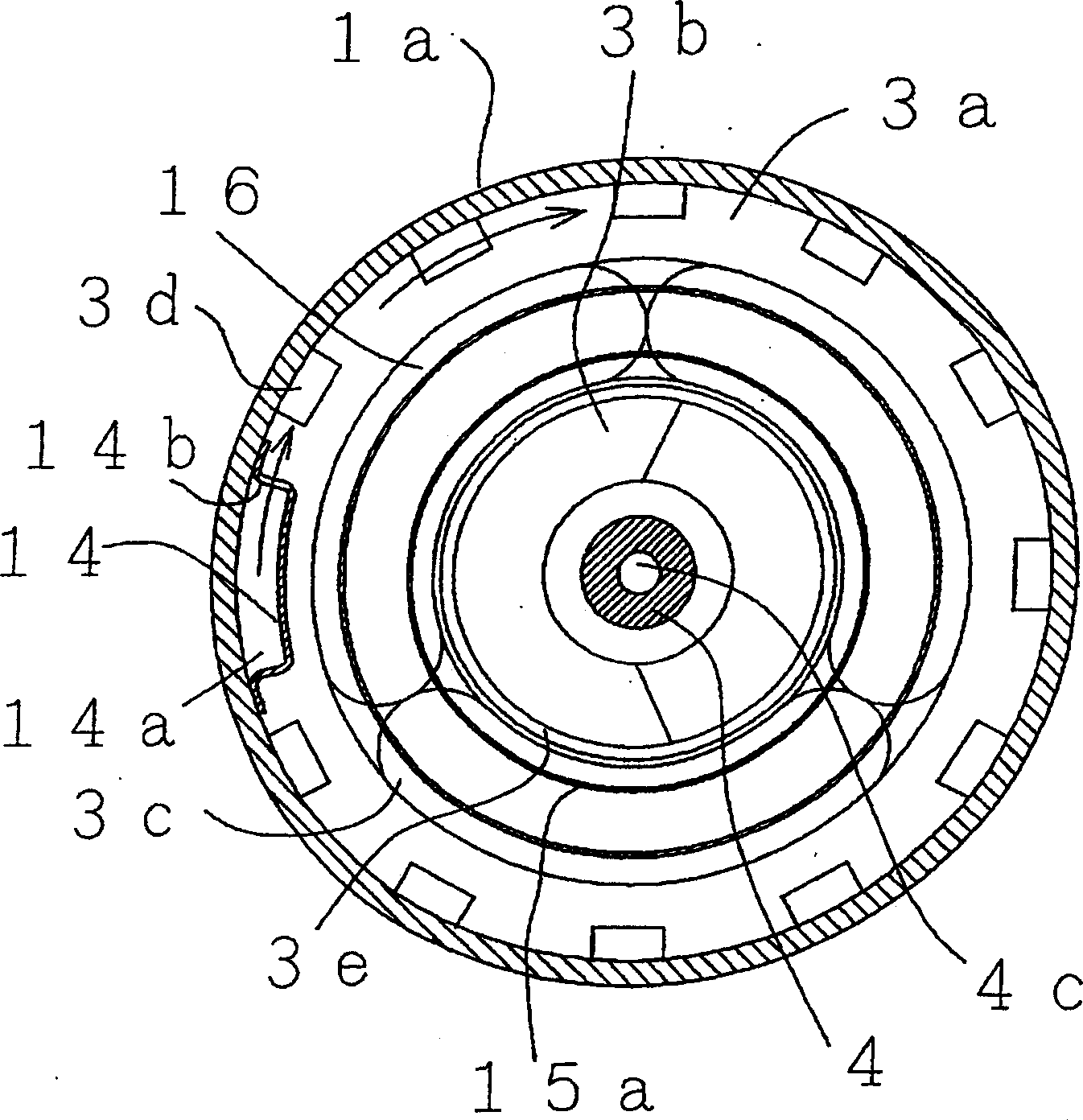

[0015] Below, refer to Figure 1 to Figure 6 One embodiment to which the turbo compressor of the present invention is applied will be described. exist figure 1 Among them, the compression mechanism 2 is arranged on the upper part of the airtight container 1, the electric motor 3 is arranged on the lower part, and the crankshaft 4 is connected up and down. The stator 3a of the electric motor 3 is fixed in the case 1a of the airtight container 1 by heat fitting or the like, and the rotor 3b of the electric motor 3 is fixed by, for example, the crankshaft 4 being press-fitted.

[0016] The airtight container 1 is based on a cylindrical shell 1a, a double chamber 1b is welded on the upper part, and a bottom chamber 1c is welded on the lower part. An exhaust pipe 1d is installed on the side of the casing 1a, and a suction pipe 1e is installed on the double chamber 1b to connect the respective compression mechanisms 2.

[0017] The compression mechanism 2 has a frame 9 on which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com